Table of Contents

Results of the study of titanium binary and ternary alloys containing vanadium and cobalt show that:

- Vanadium additions up to 16 weight-percent were insufficient to completely retain beta on water-quenching.

- Cobalt additions up to 4 weight-percent do not affect retention of the beta phase on water quenching Ti-V-Co alloys containing up to 16 weight-percent vanadium.

- While the alloys of Ti-8V-Co, Ti-12V~Co, and Ti-16V-Co responded slightly to aging at 450° C,; there was no stability of these alloys at aging times up to 24 hours.

- Although none of the alloys showed response to aging at 500° C., stability as indicated by hardness was greater for longer aging times at 500° C. than at 450° C.

- Cobalt additions to Ti-V alloys tend to strengthen the alloys more than an equal weight-percentage of vanadium.

- In alloys containing alpha at large beta-gram boundaries there was no apparent brittleness except for a Ti-8V-4Co alloy having a Vickers hardness of 317.

Titanium-vanadium-cobalt alloys solution-treated at 700° C. followed by aging 4 hours at 500° C, were characterized by moderate strength and elongation.

Although a number of investigations have been concerned with titanium-vanadium alloys, there is little reported work on the titanium-cobalt system. No published information was found on the combination of these three metals.

The transformation characteristics and the mechanical properties of titanium-vanadium alloys have been investigated for a series of alpha-beta ratios by R. J. Quigg and coworkers. It was found that at least 50 percent of the quenched structure should be metastable beta in order to obtain any sizable age-hardening response. The greater the amount of vanadium present in beta the more sluggish was the response, and each combination of solution temperature and cooling rate possessed a unique aging behavior.

Other investigators have shown that in titanium binary alloys, the beta solid solution is not retained by quenching unless the concentration of the alloying element is above a certain critical value. The critical composition is given as 15 percent for vanadium and 6 to 8 percent for cobalt. While both vanadium and cobalt are beta stabilizers, a eutectoid is formed with titanium at 9 to 10 percent cobalt.

According to Margolin, limited amounts of eutectoid formers may be used with an element, such as vanadium or molybdenum, without obtaining a titanium compound. Titanium alloys are reported to tolerate up to 5 percent chromium with 8 percent vanadium before TiCr2 is encountered.

Orrell and Fontana in their investigation of the titanium-cobalt system state that alloys below 6 percent cobalt showed only the typical acicular transformed-beta structure after quenching from a homogenization temperature of 930° C.

The alloys of this investigation were surveyed primarily to furnish information relative to the effect of cobalt on the transformation and properties of titanium containing up to 16 percent vanadium. The objective was to develop a high-strength beta-stabilized titanium alloy with smaller total alloy additions than required in a binary system, by using two beta stabilizers.

This same approach was taken by Carew and coworkers in an investigation of the titanium-vanadium-molybdenum system. It was reported that stability of the beta phase, with respect to transformation at temperature below the beta transus, was not achieved with 15 to 24 percent vanadium plus molybdenum nor with 30 percent vanadium alone.

In the present investigation, 16 titanium alloys, containing 4 to 16 per-cent vanadium and 0 to 4 percent cobalt, were studied. Assuming that a straight line in a ternary system joins the retained beta boundary points of the binary systems and that no compounds would form at compositions containing 4 percent cobalt, beta would apparently be retained in the 8-percent vanadium alloy containing 4 percent cobalt, in the 12-percent vanadium alloys containing 2 and 4 percent cobalt, and in all alloys containing 16 percent vanadium.

Materials and Experimental Procedures

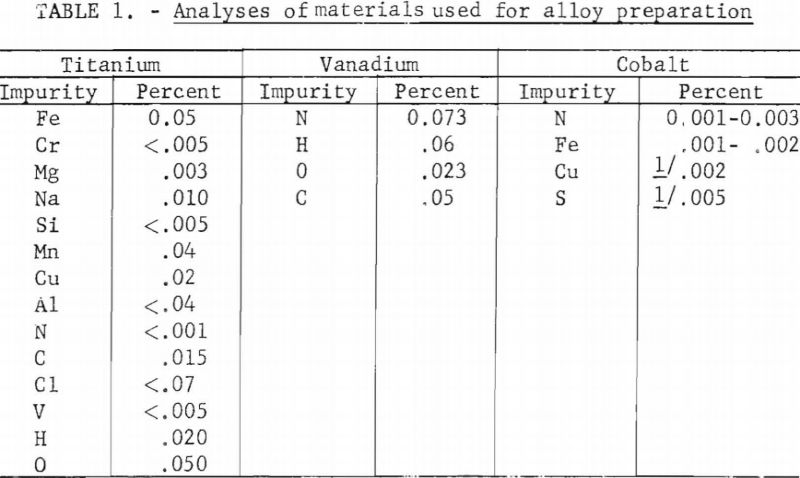

Metals used in this investigation were electrorefined titanium (94 B.h.n.), a crystalline powder low in interstitial contaminants and metallic impurities; vacuum-annealed electroplate cobalt; and commercial vanadium. The analyses of these materials are given in table 1.

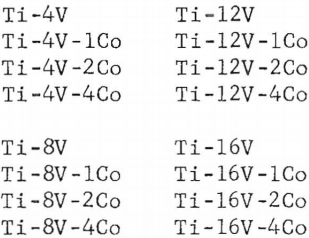

Eighty-gram buttons were double-melted in a tungsten electrode arc furnace under helium. Maximum weight loss during melting for all compositions was less than 2 percent, which is normal for unalloyed metal. The following nominal alloy compositions (calculated weight-percent) were investigated:

The buttons were machined parallel on both sides to a thickness of approximately 0.450 inch preparatory to hot-rolling.

Three hot-rolling temperatures were investigated 600°, 700°, and 750° C. Satisfactory reductions with the laboratory rolling mill were obtained only upon hot-rolling at 750° C. All alloys were given a 15-minute presoak at temperature and a 3-minute reheat between passes of approximately 15-percent reduction in thickness. Total furnace time was 45 minutes, and there was no excessive scaling. The light oxide coating that formed was readily removed by light sandblasting. All alloys were readily rollable to a thickness of 0.060 inch, with only minor edge and surface cracking.

Specimens for heat treatment were ½ inch by ½ inch by 0.060 inch in size. All treatments were conducted in a helium atmosphere gettered by titanium turnings.

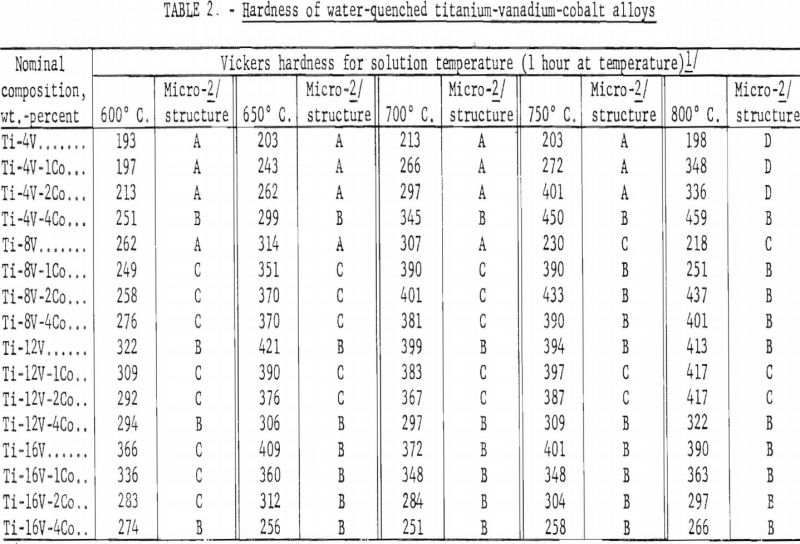

The solution treatments investigated were 600°, 650°, 700°, 750°. and 800° C. for 1 hour, followed by water-quenching. Aging was at 450° and 500° C. for ½, 1, 4, 10, and 24 hours. Vickers hardness (10-kg, load) was measured for each time interval. Hardness data reported in tables 2 and 3 represent an average of three to five hardness impressions.

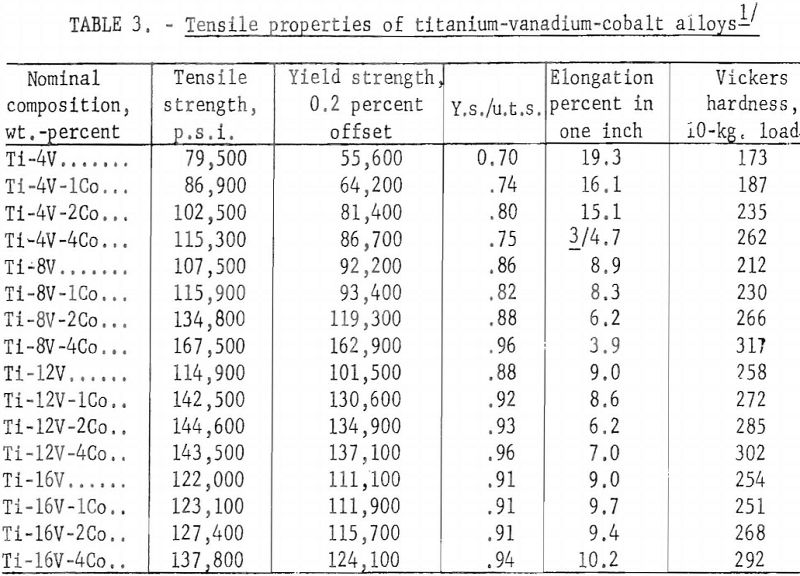

Tensile specimens, ¼ inch wide with a 1-inch reduced section, were prepared with the long axis of the specimen parallel to the direction of rolling. Tests were performed at a loading rate of approximately 500 pounds per minute and results reported in table 3 average two to five tests.

For metallographic examination, all alloys were mechanically polished and etched with 1.5-percent HF and 3-percent HNO3 aqueous solution (Krolls etch).

Results and Discussion

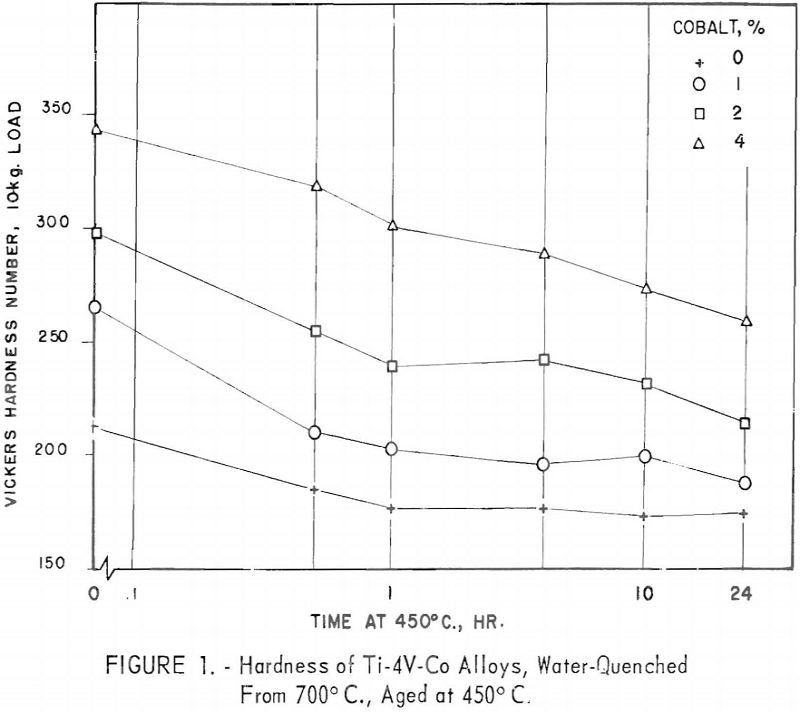

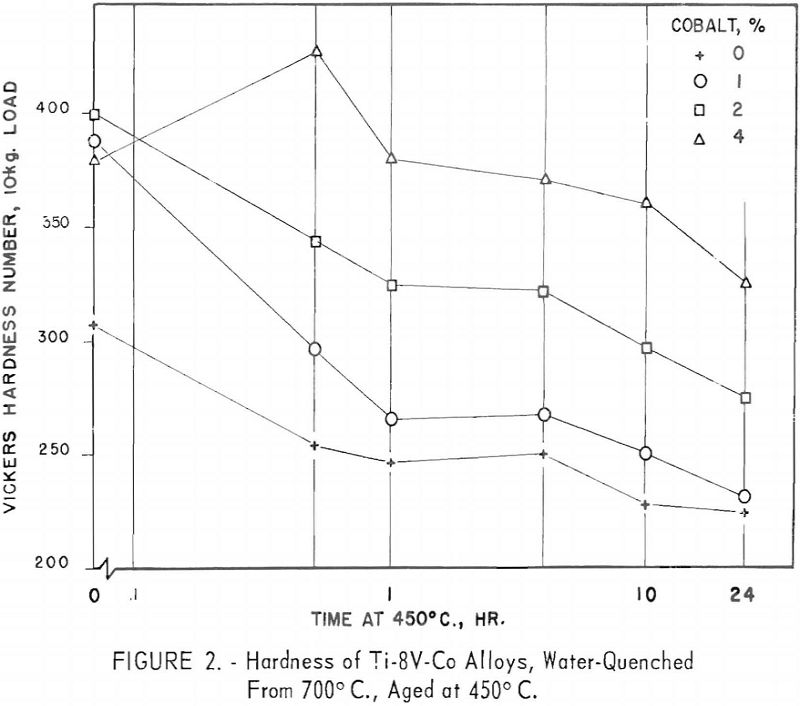

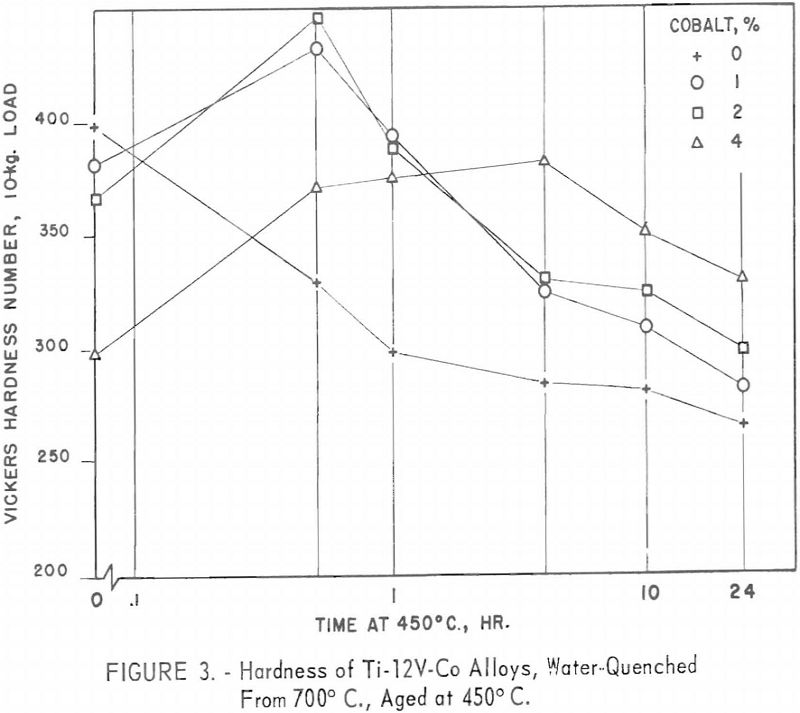

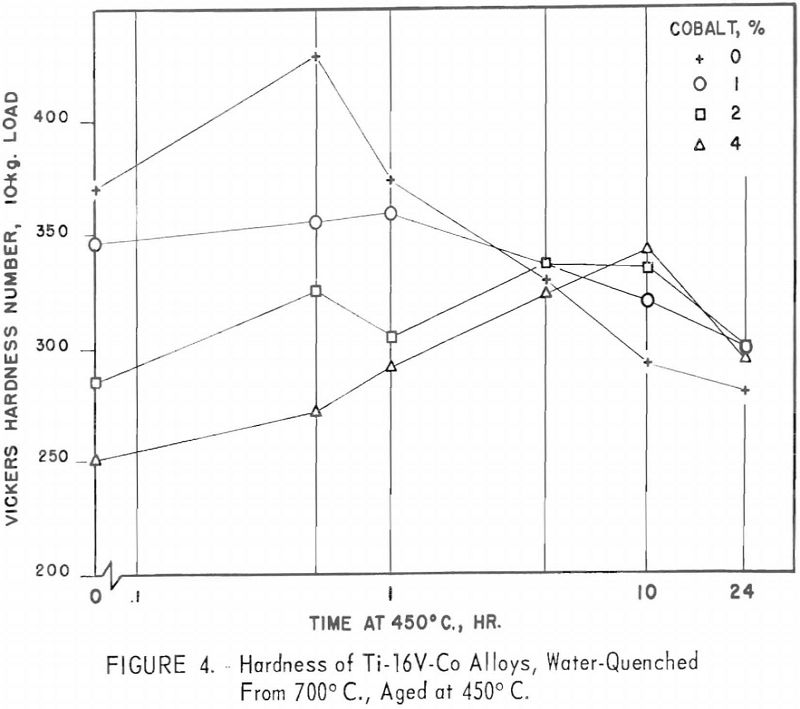

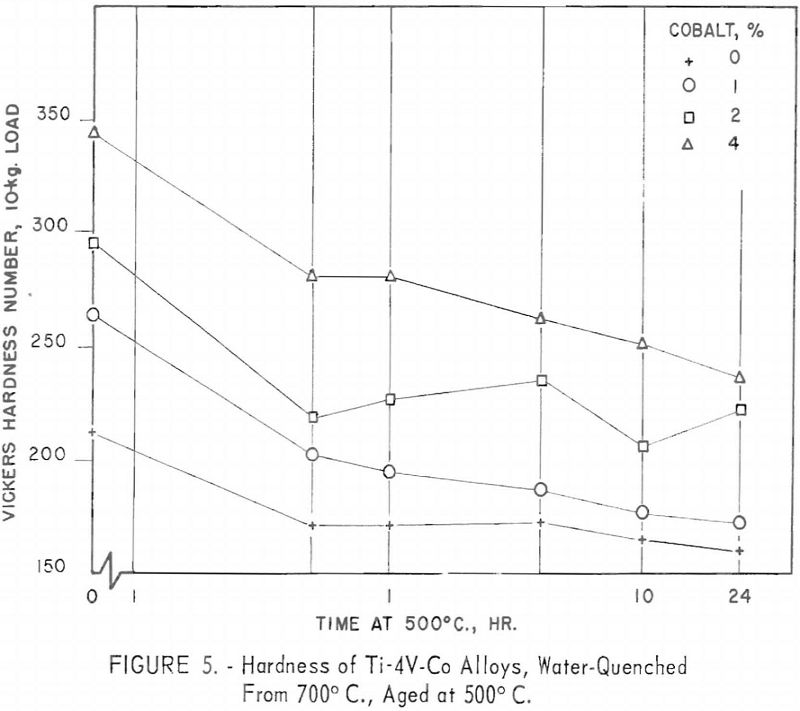

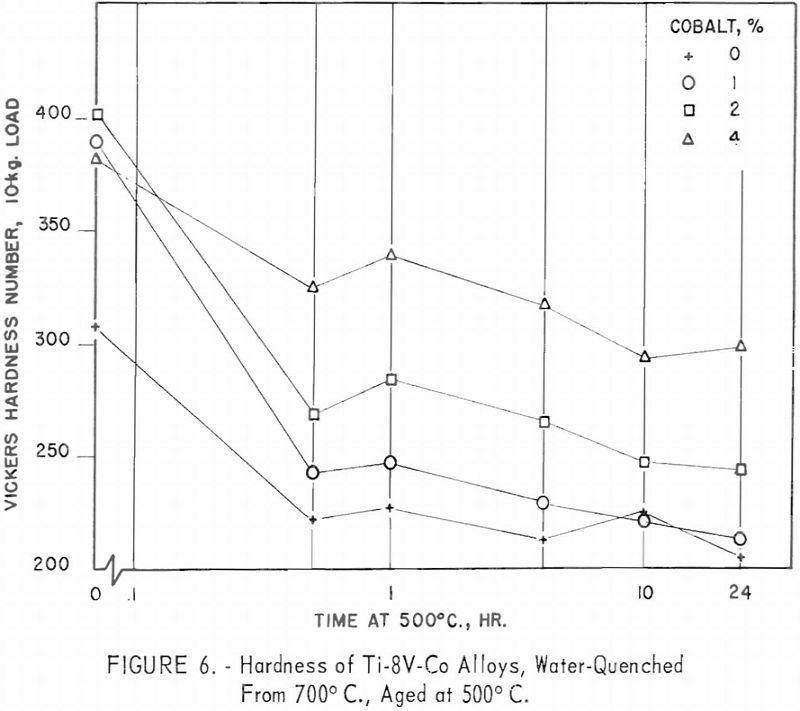

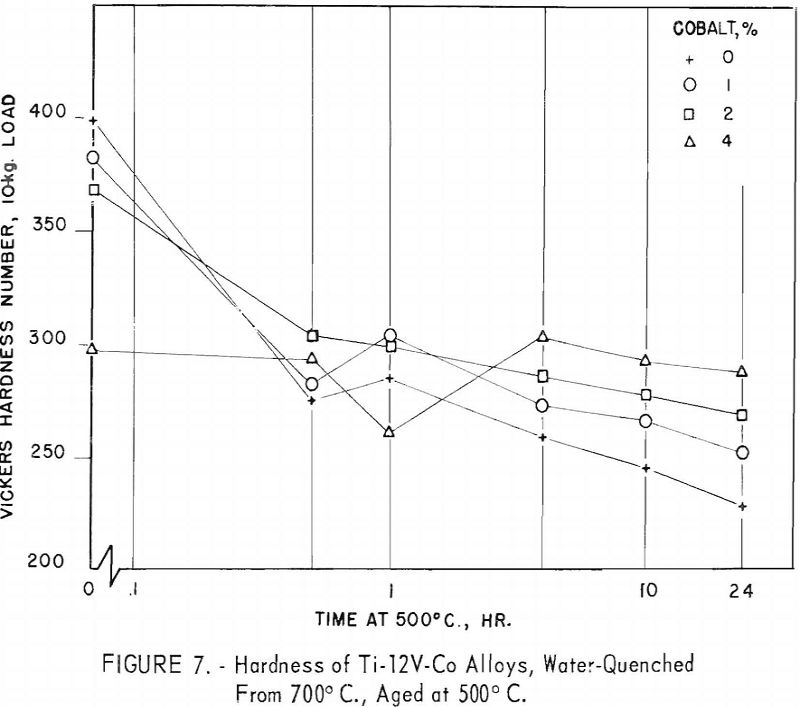

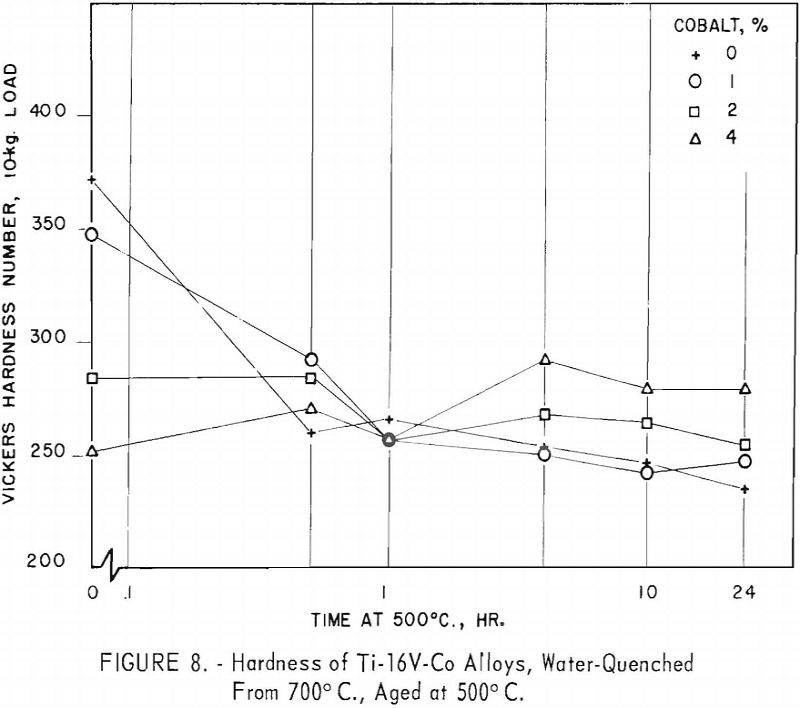

The aging response of all alloys was determined after solution-treatment at 700° C for 1 hour followed by water-quenching Specimens of these alloys were aged at 450° and 500° C. and the hardness was determined at ½- to 24-hour intervals. The results of these aging studies are presented in figures 1 to 8 inclusive. The 700° C. solution temperature was chosen because this temperature yielded intermediate hardness (table 2) for the range of solution temperatures investigated. The 750° and 800° C. quenches produced high hardness (some above 400 Vickers), indicative of omega brittleness.

The hot-rolling temperature of 750° C. was in or close to the beta field for all alloys except the Ti-4V, Ti-4V-1Co, Ti-4V-2Co, and Ti-8V. The structure of those alloys rolled in the alpha-beta field was a fine mixture of alpha and beta grains. The structure of alloys rolled in the beta field was fine alpha, plus some martensite in large beta grains with alpha at beta-grain boundaries. As the total alloy content increased, the amount of martensite decreased, and the alpha became finer.

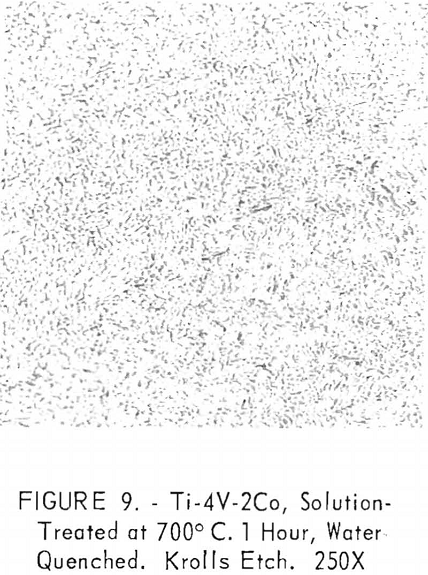

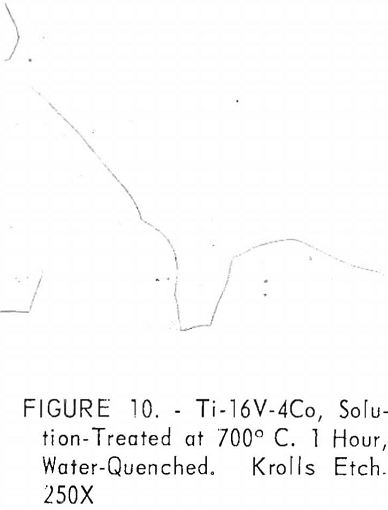

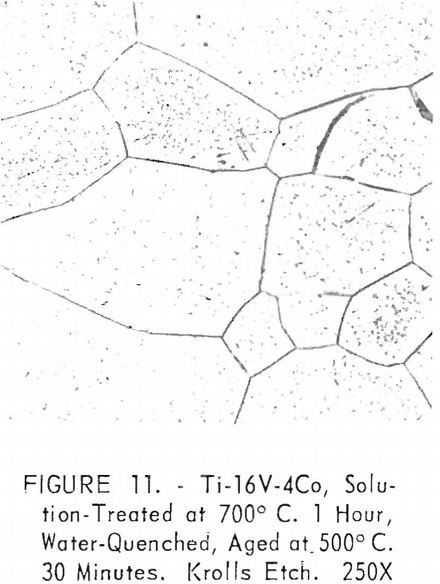

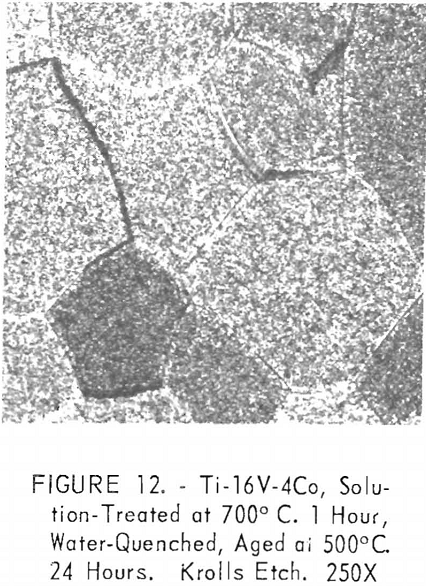

The microstructure of ternary alloys containing 8 percent or less total alloy content, solution-treated at 700° C., are shown in figure 9. This structure is essentially a fine mixture of alpha and beta grains and exhibited no visible change upon aging. The structures typical of alloys containing more than 8 percent total alloy content, solution-treated at 700° C. and aged at 500° C., are shown in figures 10, 11, and 12. The precipitation of alpha is evident after an aging time of 30 minutes and is accompanied by rapid softening for aging times up to 1 hour. Aging for times longer than 4 hours tends to coarsen the structure with little change in hardness. There was no evidence of compound formation for any of the treatments investigated.

When aged at 450° C., no hardening was observed for the Ti-4V-Co, Ti-8V-Co (except Ti-8V-4Co), and Ti-12V alloys. However, hardening may have occurred for aging times under 30 minutes. Rapid overaging has been noted in Ti-V alloys aged to 500° C. The Ti-12V-Co and Ti-16V-Co alloys showed slight response to aging at 450° C.

For the Ti-12V-Co and Ti-16V-Co alloys, the highest quenched hardness values were related to the lower cobalt compositions. This order of hardness was reversed after aging times longer than 1 hour, the higher cobalt alloys then showing highest hardness.

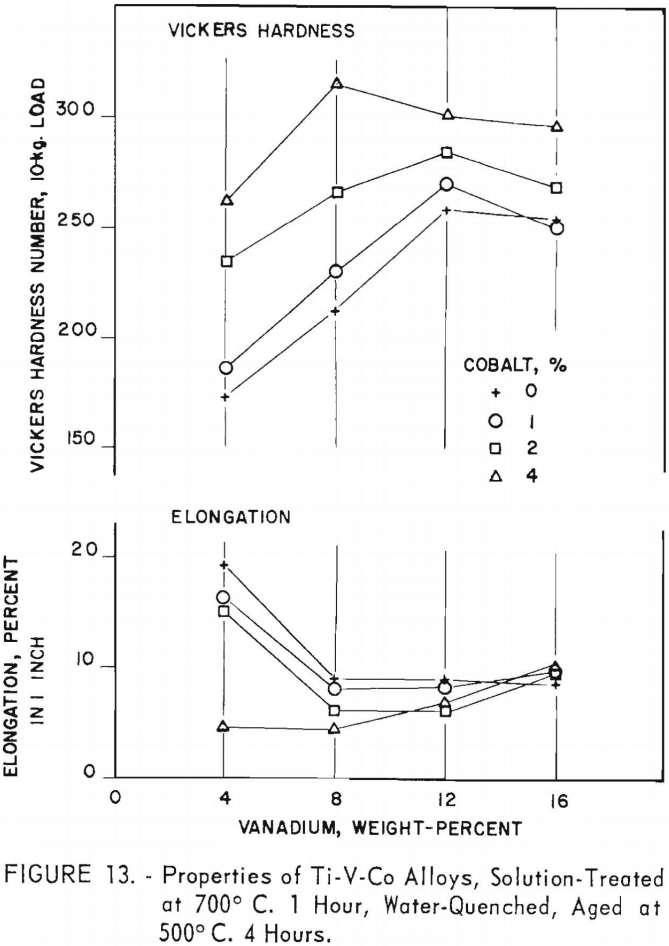

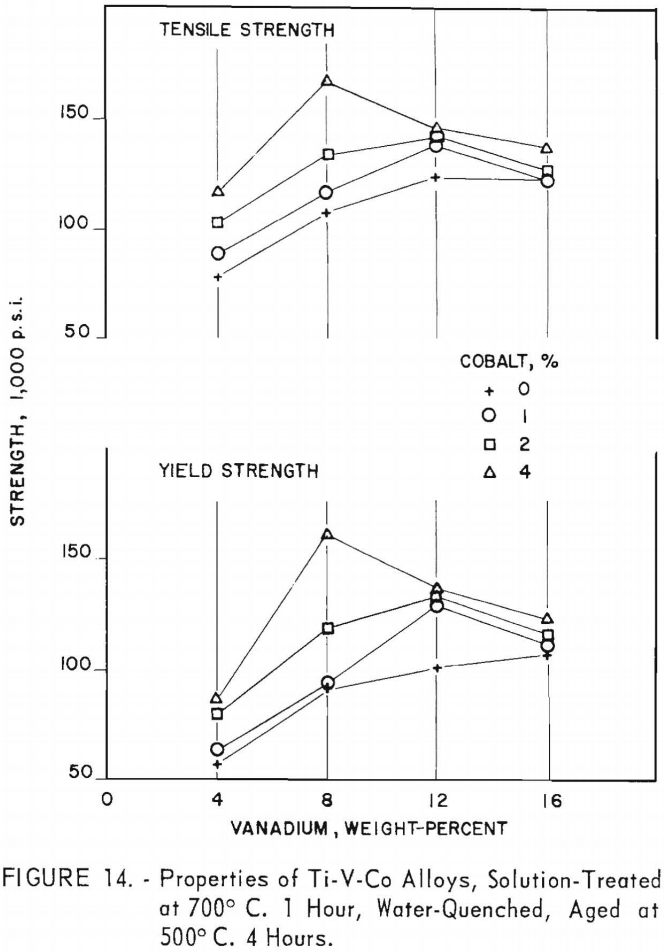

Because of the limited quantity of material available for tensile specimens, only one aging temperature was investigated. The 500° C., 4-hour treatment was chosen because the softening process appeared more complete. The tensile properties of these alloys (water-quenched from 700° C., aged 4 hours at 500° C.) are listed in table 3 and shown graphically in figures 13 and 14. Tensile strength, yield strength, and Vickers hardness increase with increasing cobalt content up to 12 percent vanadium, dropping to intermediate values for the 16-percent vanadium alloys. Elongation, 15 to 19 percent for the 4-percent vanadium alloys, drops to 3.9 to 8.9 percent for the 8-percent vanadium alloys, containing 0, 1, and 2 percent cobalt, respectively, and levels off or increases slightly for the 12- and 16-percent vanadium alloys. The 4-percent cobalt alloys show an increase in elongation for vanadium alloy contents greater than 8 percent vanadium.

While the structure of large beta grains with alpha at the grain boundaries is not desirable, no excessive brittleness appears to be associated with this structure except for the Ti-8V-4Co alloy, which had a Vickers hardness of 317. This was the highest hardness for an alloy that was water-quenched from 700° C. and aged 4 hours at 500° C.