Table of Contents

- Shaft Sinking

- Winding Engines and Equipment

- Pumping Facilities at Main Shafts

- Communication between Surface and Underground

- Ventilation

- General

- Underground Development and Extraction Levels

- Rises

- Trucks

- Methods of Stoping

- Open Stoping with Bulkheads

- Rill Stopes

- Transportation of Filling

- Main-Drive Timbering in the Orebody

- Timbering of Ore Chutes

- Prevention of Underground Fires

- Underground Staffs

- Cods

The varying physical character and large extent of the Broken Hill lode necessarily involve the employment of a variety of underground methods. The lode had its origin in an extensive fault plane traversing metamorphosed schists conformably, as a rule, with their beds of stratification. The underground waters carrying minerals in solution deposited their contents in the original cavities formed by the faulting action, and in the enlargements of these cavities due to dynamic forces brought to bear on the rocks, more especially on the hanging-wall side of the fault. This deposition was supplemented by metasomatic replacement of a portion of the original rock contents by the argentiferous sulphides of lead and zinc which form the staple products of the district.

Although the orebody is practically continuous throughout the mines, its width varies greatly, ranging from a few feet to about 350 ft. The widest portions occur in conjunction with huge folds in the enclosing country rock, almost exclusively on the hanging-wall side. The ore in these folds pitches to the south in the southern half of the field, and to the north in the northern half; there are, however, undulations in these ore channels evidently due to compression of the rocks in the direction of the channels. In the earlier days, before the orebodies had been opened up, vertical cross-sections across these bulges in the hanging wall gave the lode the appearance of the “saddle formation,” so well exemplified at Bendigo in Victoria; but subsequent development of the ore channels has long since proved that the formations in the two districts are entirely different.

The depth reached by the zone of complete oxidation of the sulphides varies from about 250 to 550 ft. from the original outcrop, while partial oxidation extends in places below the 1,000-ft. level. The result of oxidizing influences has been the production of ore of every grade of cohesiveness, from that of dry sand to that of hard compact rock.

The methods of mining followed in this field, and even in individual mines, are varied in accordance with the character of the ore. The general practice of the field is to sink vertical shafts, generally on the foot-wall side, free from the liability of disturbance from settlement due to stoping.

Where there is an assurance of depth of orebody, the levels are spaced at distances up to 200 ft., which is considered the maximum for economical working, for, although the cost of opening up each level per ton of ore commanded would be decreased by a further increase in the spacing, the extra costs due to extra wear and tear of chutes, reduced accessibility of the stopes, etc., would more than counterbalance that saving.

Shaft Sinking

The largest shafts in the district measure 13 ft. 8 in. by 9 ft. 6 in. within timbers, and are divided into three compartments—two for winding purposes and one for ladderway, and to accommodate air main, pump column, electric light and power cables, etc. The details of the shaft timbering are shown in Fig. 1. Each winding compartment carries cages capable of holding two ore trucks, end on, each about 25 cwt. capacity; draft horses are also sent up and down in these cages at the end of each shift.

Bearers, the ends of which are let into hitches-cut in the solid rock, are placed about 50 ft. apart vertically, and below them, in addition to wood blocking, each wall plate is hung from that above by means of wrought-iron hangers, as illustrated, until the weight can be taken by the succeeding bearers. Strong frames are usually hung below the lowest wall plate to protect it from flying rocks, the result of blasting operations when sinking.

The maximum distance of the timbers from the shaft bottom during sinking varies according to the nature of the ground. The general practice in sinking these shafts is to employ four reciprocating rock drills on two stretcher bars, and to arrange the holes so as to be able first to fire out a central cut across the shaft, after which the holes adjoining the cut are fired in succession by using varying lengths of fuses. A depth of about 6 ft. is gained with each firing. Electric firing has been tried on various occasions, but was not adopted because of the greater economy in explosives resulting from the use of time fuses, which enable the burden on the various holes to be successively reduced.

In sinking Delprat shaft on the Proprietary mine from the surface, the bottom of the shaft was illuminated by means of rays of electric light thrown down the center by means of a parabolic-reflector and a mirror placed on the surface at an angle of 45°. In order to avoid shadows, the dividing timbers were left out until the sinking was completed. . Operations were thus materially facilitated, especially as there, was a considerable quantity of dripping water. Powerful first-motion engines and buckets of 20 cu. ft. capacity were used for sinking direct from the surface, but in deepening existing shafts considerations of available room tend to restrict the size of the hoists, which, in such cases, are usually geared. As these lifts, however, are smaller rapid hoisting is not so important. Travelers, whose depth, to prevent jamming, is not less than twice their width, are used to guide the bucket through the timbering; these work in ordinary runners.

The Kinetore shaft on the Central mine was recently sunk for a time with the use of hammer drills held in the hand, the maximum depth of hole being from 1.5 to 2 ft. The system was, however, not persisted in, because with the particular type of drill used the effect of the vibration was too severe on the men using the machines continuously for the considerable periods necessary, and, in addition, the substitution of short lifts for the deeper sinks to which they were accustomed was not favored by the contract miners. So the reciprocating drills were finally reverted to. There seems, however, to be every probability that shaft sinking may be advantageously carried out by this method with machines having less vibration, and further attempts will no doubt be made in that direction.

Where new shafts are being provided to command existing workings, the practice is to put up rises about 6 ft. square from the various available levels, subsequently stripping the sides to accommodate the shaft timbering. Rising is effected with the modern air-fed hammer drills using water, either through hollow steel or by means of sprays, to allay the dust. By this method shovelling is avoided; the expenditure in explosives is reduced; delays caused by baling water are eliminated; and power is saved in hoisting, since the broken rock can generally be used for stope filling on the various levels.

Winding Engines and Equipment

The general practice of the field is to employ first-motion, double-drum steam engines, fitted with auxiliary steam cylinders controlling the brake release and reversing gear, and thus reducing to a minimum the physical exertion of the drivers. The function of the auxiliary controlling the brakes is to keep the brakes off, as counter-weights supply the power for the brakes, which would be automatically applied in the event of failure of the steam appliances. Post or pillar brakes are generally used with Ferodo linings, those having parallel motion giving the best results. Piston valves are generally used on these engines, the cutoff being generally at a fixed position and full steam applied until the cage is within a safe distance of the surface, when the steam is turned off; but in the case of the South mine more elaborate expansion gear is employed with satisfactory results.

The exhaust steam from the principal winding engines of the district is discharged into accumulators feeding the exhaust-steam turbines which furnish electric power for general purposes.

Revolving indicators enable the driver to watch the position of the cages, and in the case of Delprat shaft on the Proprietary mine the view of the brace, etc., is obstructed so that the driver’s attention shall not be diverted, thus requiring him to work only according to his signals and indicators.

On the larger engines plough-steel wire ropes of Lang or Albert lay are used, 1¼ in. in diameter with a factor of safety of about 10 or 12 on dead pull when new, and having six strands of 17 or 19 wires, the former where the pulleys and drums are of ample diameter.

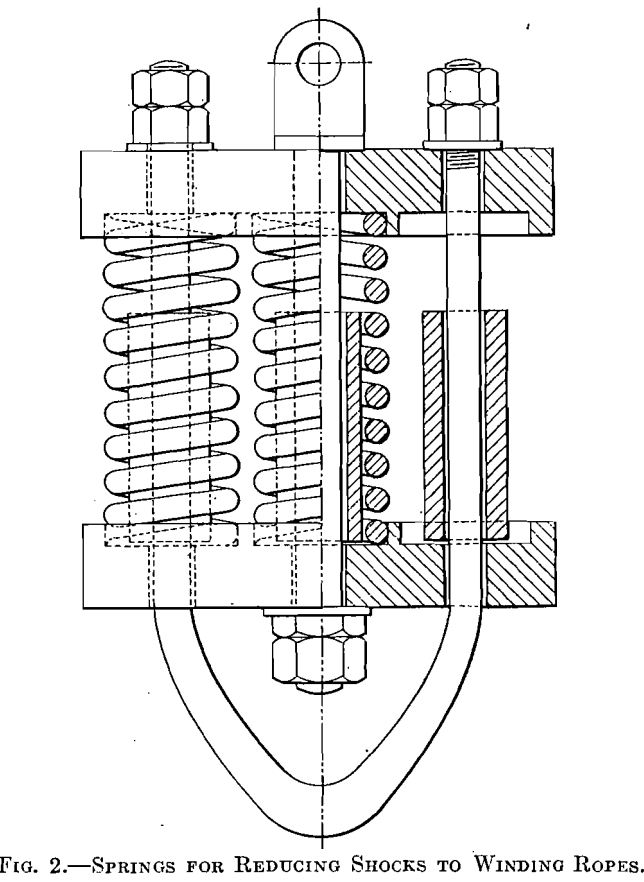

On the Proprietary mine springs are used, as shown in Fig. 2, near the attachment of the ropes to the cages to take up the shock when the weight is coming on to the rope with a view to increasing the useful life of the ropes.

Regarding safety appliances to guard against overwinding and breakage of ropes, in addition to those on the cages (on which grips engaging the sides of the timber runners are favored), safety hooks of the well- known Ormerod type (see Fig. 3) are used, which disengage the rope on passing through thimbles placed below the pit-head pulleys and support

the cage. In addition, safety chairs are fixed above the top brace to catch the bottom of the cage if the other appliances fail.

At all shaft entrances lattice-work iron doors, balanced, are provided to prevent persons entering the shaft, and in addition heavy bars of steel rail, also balanced, are used to prevent trucks entering the shaft.

Poppet heads of the gallows-frame type are in general use, constructed of steel lattice framing, built clear of the engine house, which is generally of masonry.

The equipment of the top brace, or landing, includes a revolving tippler on to which a truck of ore can be tipped by an ore inspector whose duty is to bring to the notice of the underground manager any cases found where mullock in undue quantity, or pieces of ore too large for the breakers, are included, in which cases offenders are punished by suspension or dismissal, according to circumstances.

As a prevention against fire being communicated from the surface

works underground, or vice versa, a section of the shaft timbering on the Proprietary mine is cut out just below the surface chairs; heavy plate-iron doors are hinged to the sides and can be closed at short notice. Like all the safety appliances, these are thoroughly tested periodically to insure their efficiency when needed. In conjunction with these, plate-iron doors are provided at all approaches to the shafts to control the air currents in case of fire.

In only one instance in the district, namely, at the Zinc Corporation, is the system of skips with ore pockets below the plats used. It is found generally more convenient, in view of the moderate tonnages hoisted at individual main shafts, to use cages, which are then always available for use in hoisting and lowering men, horses, and material as well as the ore trucks. Moreover, the latter system enables the weight

of each party’s trucks of ore from any number of levels to be definitely ascertained at the single weigh-bridge on the surface.

In the case of the Zinc Corporation, owing to the regularity of the orebody and (in the upper levels) its moderate width, it was practicable to pay contractors by measurement, so that the disadvantage last mentioned as attaching to the use of ore skips does not exist.

At Delprat shaft on the Proprietary mine, where as many as 1,650 trucks of ore have been hoisted from, about six levels in an 8-hr. shift, after changing half the number of men employed on the shift and with the usual 20 min. for crib, a back-shunt is provided at the back of each plat, into which the empty trucks are pushed; from the end of this back-shunt the trucks automatically gravitate to a line parallel with the full lines and laid on the requisite grade, and of sufficient length to accommodate 25 or 30 empties, which are taken away by horse traction in “rakes” of 10.

The use of cages (Fig. 4) capable of carrying two trucks, end on, facilitates rapid caging, and this is further assisted by the use of a sliding bar which retains the empty trucks in the cage on the loading side of the shaft, and vice versa as regards the loaded trucks, rendering it unnecessary to handle more than one bridle at each caging or uncaging of trucks, as the sliding bar is automatically pushed to and fro into position by the moving trucks.

For horse traction, the general practice is to use trucks with wheels fast on the axles; but where the distance of the shaft from the ore chutes is short, hand-trucking is practiced, and in some of these instances one wheel only on each axle is fast, facilitating trucking on curves.

At the South mine a system of automatic signals has been introduced for the purpose of indicating to the engine-driver whether the chairs are in or out for each level; this is achieved by the use of electric contacts attached to the chairs and a series of electric lights in front of the driver in the engine room. Although this device is claimed to have proved itself reliable, the managers of other mines, where the shafts are probably wetter and short-circuiting is, therefore, more likely to occur, have preferred to guard against chairs being left in by requiring the driver, in changing over to a new level, to lower the cage slowly when passing levels for the first time.

Pumping Facilities at Main Shafts

As the various levels are laid out on a gradient of about 1 in 190, or steeper, toward the shaft, the drainage of the mines is conveniently concentrated at the shaft plats, where excavated tanks are provided below the rail level at the pumping stations to hold sufficient water as sumps. Electrically driven geared pumps of various makes are used, pumping against heads of from 400 to 1,000 ft.

Communication between Surface and Underground

Telephonic communication between the surface and the various levels and isolated portions of the principal mines is established by connection of these places with the surface mine exchange. Hoisting signals are given by means of balanced wire ropes, the moderate depths of the local mines permitting the satisfactory use of this means of communication.

Ventilation

Artificial ventilation is generally practiced on the field, fans of the Capel type and of about 70,000 cu. ft. per min. capacity against 3-in. water gage being most common. Other types of similar capacity represented here are the Waddell and the Sirocco. On the Proprietary mine, which covers ¾ mile, are both a Capel and a Waddell fan. In general

use these fans exhaust the air but ducts and doors are provided, as shown in Fig. 5 by which these fans can be promptly made to act as pressure fans in case of fire making a change of draft advisable.

General

Magazines capable of holding sufficient explosives for 24 hr. are established on each important level, and generally, in conjunction with them, stores of tools are provided, the rule being that no new article will be issued before the return of the old. All tools, except drills and picks, are branded with numbers for identification. Explosives are issued to contractors and charged against their contract, at the expiration of which a statement of earnings and all details is furnished to them. The majority of the contracts are for 4 weeks; but in some cases where the working conditions are liable to change considerably during the period of contract, they are for 2 weeks only. In some other cases, where conditions remain unchanged, contracts are sometimes let for several months.

Tools are provided free of charge, but any loss sustained other than through fair wear and tear is chargeable to the contractors, who constitute the great bulk of the workmen. Wages-work was general in stopes up to 1892, but the efficiency of the work fell so low that contract, or piece-work was insisted upon, and generally introduced after a strike lasting 18 weeks. Owing to the higher earnings prevailing under this system, the majority of the men now favor contract work, which, in view of the inherent difficulties of supervising wages-men in so many isolated localities, is the only practicable means of securing efficiency.

Underground Development and Extraction Levels

The general practice of the field, except where the lode is narrow, is to place the extraction levels in settled country, at a safe distance from

the lode on the foot-wall side. These are generally about 8 ft. wide, and carry double tracks.

Where the orebody is wide, crosscuts are run through the lode every 100 ft. In some mines where time of completion is of great importance, a special rock-drill carriage run on rails is used, on which four drills are mounted, enabling the face to be bored out quickly. The best of these, namely, the one used on the Central mine, is illustrated in Fig. 6, The most economical method of driving, where time permits, is to allot two faces (if available) at convenient distance apart, to each party, so as to permit the handling of the broken rock by truckers, thus limiting the miners to operations requiring more skill.

The favored system of firing is that in which the whole face is bored out before dismantling the machines, the holes for the initial cut (which is generally formed in the center of the face) being fired first, of course, and the surrounding holes in rotation, so that by varying the lengths of fuses the burden on each hole may be lightened by the preceding firing (see Fig. 7).

Rises

Since the advent of the air-feed or telescopic hammer drill, vertical connections have been made to a greater extent than formerly by this means instead of by winzes. The advantages of rising are numerous. There is less risk of injury to miners, as the danger of stones or tools, etc., falling from bucket or sides of winzes is absent. The facilities for handling the broken rock are greater, shovelling on a rough bottom being eliminated. The engine-driver and braceman are dispensed with. There is improved ventilation, since the timbering of the rise can be carried closer to the face than in winzes, enabling effective use to be made of incoming fresh air whether induced by fans, air or water jets in ventilating pipes, or by curtains in adjoining drifts. The light weight of modern rising drills facilitates the work of rigging the machines in the most advantageous positions. Finally, in rises there is the absence of trouble from water; the greater facilities for detecting missed holes; and the fact that missed holes are less likely to occur in rises than in winzes, which are usually wet. Another advantage of rises as compared with winzes is the better ventilation of the former, heavy CO2 gas tending to lie on the bottom of the winze.

The modern hammer drill makes much less dust than the reciprocating drill, and the small amount produced is easily laid by using water in the hole through hollow steel or water sprays playing on the collar of hole. Although for the past few years the Regulations under the Mining Act require a water supply wherever rock-boring machines are in use, it may be mentioned that for years before this rule came into force, all the hard-ore stopes in the Proprietary mine were reticulated with water under good pressure, enabling water jets to be used when boring; it was recognized that any condition tending to injure the health of the workmen called for remedial measures, not only for humanitarian reasons but in the interests of the industry generally.

It has sometimes been sought to limit the height of rises by statute, but this is unnecessary, since excessive heights are prohibitive by reason of expense in handling tools, timber, etc. Various systems of timbering are employed. In some cases the rise is simply divided into two compartments by timber, lined on the side which is to be used as a chute for the broken rock. The other compartment carries the ladderway, water and compressed-air pipes, and 10-in. pipe for ventilation. Two square sets are also used, especially where the ground is not hard, and the extra size of the rise is therefore not objectionable on the score of expense.

Another method of timbering is the “box” rise, in which three compartments are formed in the same way as the two above described, the central compartment being used as a chute, and kept always nearly full.

By placing a curtain in the drift or crosscut opposite the chute, the air is made to travel up one side of the rise to the top and down the other. The extra length of this class of rise leads to increased cost, but those favoring it claim an advantage through having no ventilating air pipes to trouble about and to protect when firing—a precaution often neglected by the men.

Trucks

A simple form of ore truck is used where horse traction is employed. The bearings are so made as to permit the automatic greasing of the axles in passing revolving greasers. End- and side-tipping trucks are used for handling mullock, etc., and for filling stopes.

Methods of Stoping

Where the ore is friable, and therefore not self-supporting, the square-set system is now universally adopted, using sets of sawn 10 by 10-in. Oregon pine, generally 6 ft. square and 8 ft. high from center to center. Because of several serious underground fires, attempts have been made, especially on the Proprietary mine to replace this system by the crosscut and others. In the former case, successive horizontal slices about 6 ft. wide by 7 ft. high were taken out and filled, and any drift timber used in the lower floor was drawn when the floor above was being stoped, tapered legs being used to facilitate this. Owing to the increased labor involved to both miners and mullockers, and the slow rate at which large bodies of ore can be worked, square sets were reverted to.

In places where the ore was sufficiently self-supporting, sloping stopes taking out slices 10 to 15 ft. wide were tried. The cost of handling the ore and mullock filling was very low; but by reason of variations in the strength of the ground what appeared a perfectly safe width at one time might be unsafe later on and this system was also discarded, except in isolated cases.

In using square sets for stoping these large masses of ore, it was the rule in the earlier days to work out the ore in stopes 100 ft. high. Although this has been successfully done in many cases, it is now held by those who have had the heaviest ground to work that in the long run it is much safer and more economical to divide the height into two lifts of 50 ft. each. When stopes as high as 100 ft. are worked, the accumulated shrinkage due to the drag of the filling on the timbering in the stoped-out ground is very apt to leave considerable cavities between the old bottoms overhead and the top of the stope, rendering the blocking at the top of the stope useless. In some cases the old bottoms and filling above gradually subside and harmlessly follow the top of the stope below, but in too many cases there is a sudden drop of hundreds of tons on the top of the working stope, the effect of which may be its complete collapse, and great expense in making fresh arrangements to take out the ore, much of which will have fallen into and mixed with the filling, besides being much more expensive to mine than if the collapse had not taken place.

Where the ore is sufficiently cohesive to enable driving laths to be dispensed with to support the back, overhead stoping is practiced, because the ground can be blasted to greater advantage, and with less explosives per ton, than in underhand stoping. In heavy ground, however, or, as a rule, where a slice of ore under old stope bottoms is being taken out, underhand stoping is carried out, the miners first securing the ground immediately above the set or sets to be carried down, this securing being done with the aid of cantilever booms supported on posts set on the cap at the bottom of the set, driving laths being used if the condition of the bottom requires them (see Fig. 8).

The back or backs of the sets, if more than one are being carried down at a time, having been secured, the ore is then removed for the full dimension required to accommodate the square sets, horizontal breasters of 10 by 2-in. timber with joggled ends being inserted to secure the sides; and when these reach the floor of the set, the square sets themselves are placed in position and blocked. Before taking out the next lower set, the bottom timbers of the square set, in the case of the Proprietary and some other mines, are hung from the top timbers by nailing two laths to each pair of timbers, or, as in the Central mine, by connecting adjoining timbers by means of iron rods about 1 ft. long having spiked ends, about 4 in. long, bent at right angles, that can be driven into the timber. The broken ore is put into chutes formed in the square sets in the usual way, and moved as the stoping advances.

When all square sets from top to bottom of the run have been put in, the hanging laths and irons are, of course, removed and used in other sets as required. There is very little strain on these hangers as all the top weight is taken by the boom in the top set and the weight of the sets below is taken up by the blocking.

In stoping ore of a dry sandy nature, common in the oxidized zone of the Proprietary mine, great assistance is obtained from the use of water, sufficient of which is used in a narrow trench to soak into and wet the ground against which the breasters will be placed. By this means the danger of a run of ground is reduced to a minimum.

Where back-laths have to be driven in dry running ground, the work is greatly facilitated, besides being made healthier, by wetting the material in the back with the aid of pointed pipes having outlets on the sides.

Another practice in vogue in the Proprietary and other mines is the use of screw jacks for driving the laths “home.” Hammering not only destroys the lath before it gets home, if driving is difficult, but the vibration tends to set up a run of ground.

With regard to the location, and size of square-set stopes, the practice generally adopted is to carry the stope across the full width of the ore body, so that the stoping advances in the direction of the course of the lode, thus minimizing the effects of pressure on the stoping from the hanging wall, which, of course, becomes heavier as stoping proceeds. The extent to which stoping is allowed to advance before being filled depends on the prevailing conditions; but, in general, two sets wide by as many sets across the stope as possible are filled at each mullocking, leaving one vacant run of sets against the face. In the case of heavier ground, it is often necessary to paddock off the sets close to the working face, leaving single vertical gangways for the full height of face to give the required points of access to the face for re-starting the stoping.

The material most commonly used for filling is the residues from the flotation plants, but in the case of the Central mine, where there is much heavy moving ground and where mullock filling is obtained cheaply from a quarry immediately over the workings, the use of tailings was discontinued. Where tailings are used, as in the Proprietary mine, the sets are closely lined with 10 by 1-in. Oregon planks, and these are strengthened by two upright 10 by 2-in. laths wedged tightly between the caps. Where mullock filling is employed, 5 by 1.5 to 2-in. laths spaced 4 in. apart are used, buttressed where necessary in the same manner as is done with the 1-in. planking.

These buttress pieces are removed just prior to the filling of the succeeding stope. The bottoms of the square sets are covered with 2-in. planking, the space between which and the solid ore is filled with ore, to prevent breakage of the planking under the pressure of the overlying filling.

Open Stoping with Bulkheads

Where the sulphide ore is still in its original solid condition, free from decomposed veins and vugs, stoping is carried out without the use of square sets except for chutes and ladder-ways. The stoping begins at the various crosscuts, and where these are not already connected by driving along the orebody, a stope about 20 ft. wide by 16 ft. high is carried each way, generally along the foot wall, with a view to connecting with the adjoining crosscut and establishing ventilation. The sill-floor stope is gradually extended until the entire width of the lode is stoped out for the height above mentioned. These excavations frequently exceed 100 ft. in width, and may in some cases attain a length of 300 ft. Pigsties, or bulkheads, 5 or 6 ft. square, of 10 by 10-in. timbers crossed, are built from 12 to 15 ft. apart to support any ore likely to flake off. Excavations of this size are not common, as it generally happens that pillars of ground, either poor ore or country rock, occur that serve to support the back. No hard and fast rule can be laid down as to the size of these excavations, so much depending on the nature of the ore, its freedom from floors or horizontal cracks or seams, the nature and configuration of the inclosing country rock and walls, which may converge as depth increases, or vice versa, making wide stopes more or less safe respectively.

The extent to which pillars are left, whether because too poor to mine or because needed temporarily as a support to a shaft or other working, is also a factor affecting the area which can safely be undercut. Each case must therefore be decided by the management in view of all the conditions.

The work of placing in position the permanent main drift and cross-cut timbers can proceed as soon as blasting operations on the side of the stope are sufficiently remote to permit this to be done without risk of the timbers being thrown down, and when these have been placed and a sufficient area of filling has been put into the stope, the second stope can be started, allowing the rest of the sill-floor stoping and filling to proceed simultaneously with the stoping of the second slice. This and each subsequent horizontal slice is taken out 8 ft. high. The general practice of the field is to cover the sill floor of the stope, i.e., on the level, with 4-in. planking to enable the stoping below to approach the old bottoms with safety; possibly 3-in. planking might be substituted to advantage.

The filling is taken out of chutes into end- and side-tipping trucks, and tipped over the whole area of the stope, and the space between the top of filling, i.e., the rail level and the back of stope, usually from 4 to 5 ft. high, is again dotted with pigsties to support the back. The bulkheads are usually removed as the filling advances, although occasionally one is left and buried should the condition of the back render this necessary. It is considered safer to build bulks at regular intervals rather than only at such places as the supervising officers consider necessary, but to increase the number if occasion requires it.

In stoping hard ore against a weak and overhanging wall in the Proprietary mine, the open stope was worked in two floors (Fig. 9), the higher of which was against the wall in question, and by this means a minimum extent of wall was left unsupported, as filling was introduced to support the wall as early as possible, and the back, as seen in cross-section, was thus kept in the most favorable shape to resist and support the hanging wall.

The height to which these large stopes can safely retain their full

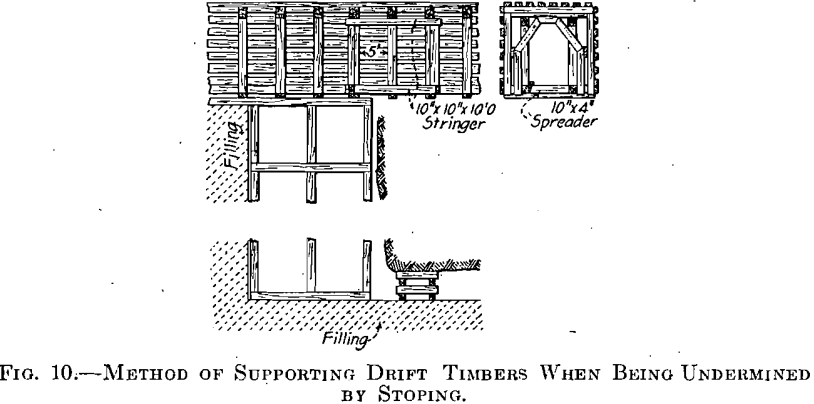

width depends on the conditions regulating their extent in the first instance, but the local practice is to discontinue using the open stope or bulkhead system when there remains from 25 to 30 ft. of ore under the level above. This slice is stoped out on the square-set system, underhand, if the ore is sufficiently cracked and broken to require it (Fig. 10). The bottom of the square sets is laid on the filling, and especially where tailings are used, scrap timber is first laid to give added support.

As the mining of these arches involves less heavy firing than in the open stopes, light reciprocating drills of various types, weighing about 120 lb. and capable of being quickly rigged on stretcher bar, are generally used. The ore in these cases is more or less broken as the result of the enormous pressure concentrated on the arch from the hanging wall, and in consequence does not lend itself to heavy firing, especially in contact with the square-set timbering which might be shot out, bringing about the loss of the stope. In some cases, the ore is sufficiently cracked and broken to make the use of hammer drills held in the hand advantageous. Difficulty is met with in getting the miners always to use water with these drills in the interests of their own health, and this also applies to the ordinary “popping” of rocks for which these drills are also used.

For the short holes necessary, the drills will generally clear themselves with the aid of the water spraying into the hole, and the exhaust air from the machine; but in many cases rather than submit to being slightly splashed with mud, men risk their health by working the machines dry and inhaling dust unnecessarily. It is too often forgotten that when hand drilling was employed for popping purposes the mud had to be periodically scraped out, and in those rare cases in which the popper does not clear itself the hole can be scraped out as of old.

Reciprocating rock drills with cylinders 3¼ in. in diameter are generally used in the solid ore, since with these, approximately horizontal holes can most conveniently be bored in the backs, enabling regular and reliable roof to be formed. Telescopic drills were tried for general stoping, but these tend to leave an unsafe back.

As many holes as practicable are bored at each setting up, and these are fired by ordinary fuses cut to lengths to give the desired rotation of shots, blasting gelatine (92 per cent, nitroglycerine) being used so as to effect the maximum of shattering of the ore to save spalling. For the same reason, simultaneous firing with electric fuses was, after making tests, found uneconomical, as the ore came down in much larger pieces entailing added expense in “popping” and spalling. The firing of one hole at a time results in numerous cross-breaks in the ore and reduces the cost of breaking up the ore to the size required by the mills, i.e., about 10 in. in diameter.

Another disadvantage of electric firing in stopes was that the excessive vibration set up in firing all the explosives at one time was a source of danger, as it would tend to weaken the backs of stopes and lead to accidents through falls of ground.

A modification of the open-stope or bulkhead system of stoping was made use of on the Proprietary mine, where it was desired to obtain the maximum output of ore from a given length of lode; this applied particularly in exceptionally hard portions of the lode, where the cost of sinking winzes was excessive, and the lode had less than the usual width. The system may be described as an adaptation to lode mining of the long-wall principle in coal mining. Several floors of stoping are worked at the same time, access to each face from the main mullock chute and ladderway being preserved by the provision of timbered drifts connecting the mullock chute with each stope. In this manner, any number of faces can be worked from each main mullock chute, each on a separate floor, but the maximum number actually operated was four.

The system was not extended, since the introduction of the Calyx drill enabled mullock passes suitable for sand filling to be provided at about one-quarter the cost of winzes. The holes bored by the Calyx drill were about 10 in. in diameter.

Rill Stopes

A certain amount of rill stoping has been practiced on the field where conditions favored that system of work, but this is not usual. The hanging wall of the lode is oftener weak than strong, and constitutes a menace to the workmen employed on the sloping surface of the filling, especially when near the bottom of the rill where the danger is greatest, owing to the length of time the wall has been exposed.

The nature of the filling generally available, namely, sandy tailings which never form a compact surface, would necessitate the covering of the stope with planking to prevent undue mixing’of broken ore with the filling.

Further disadvantage’s as compared with flat back-stopes are the greater difficulty of rigging the rock drills, and less favorable conditions for blasting, in that the ore is inclined as a rule to lie in horizontal layers, and lastly, greater difficulty in breaking and keeping separate worthless material occurring in the lode.

Transportation of Filling

The handling of mullock filling from the main chutes to the various stopes is to a great extent accomplished by horse traction on the Proprietary and some other mines, but where the distances are small hand trucking is more convenient.

Conveyor belts are used in a number of cases, particularly in the North mine, the Proprietary, and the Junction North, where the quantity to be handled warrants the installation. In the case of the North mine, the regularity and compactness of the orebodies has enabled the management to install a complete system of conveyors for delivering the filling to the chutes commanding the various stopes. Where the orebodies are irregular and spread over considerable distances this system cannot, of course, be economically employed.

Electric traction was introduced on one of the principal levels of the Proprietary mine, but was replaced by horse traction after being thoroughly tested. The distances to be trucked were not sufficient to compensate for the extra cost of attendance. The horse-driver acts as a trucker, also, in getting his rakes together and requires no assistant, but the more highly paid motor-driver needs an assistant to shift points, couple and uncouple trucks, etc. In addition, repairs, when necessary, are costly.

Having arranged the gradients of the levels so that a horse can draw the same number of loaded and empty trucks with equal ease, i.e.,

about 1 in 190, it is found that one horse can thus handle 10 trucks at a time containing 25 cwt. each.

Main-Drive Timbering in the Orebody

Various types of timbering for the main drives are employed, all of which give satisfactory results. Where hardwood timber is obtainable at

reasonable rates compared with Oregon, its use would be advantageous in these places. The principal methods of timbering main gangways in the lode are illustrated in Figs. 11, 12, 13, and 14.

A number of the mines use a considerable quantity of round hardwood logs for ordinary drives in heavy ground, as their resistance to crushing is much greater than that of Oregon. On the Proprietary mine these are used in conjunction with old 80-lb. rail material as caps; this is specially advantageous where head-room is deficient.

Timbering of Ore Chutes

The majority of the ore chutes in the stopes, whether square-set or open stopes, are formed by two square sets lined with 10 by 4-in. hardwood planks, spiked to the caps in a vertical position. The cost of repairs is reduced materially by the use of hardwood, in spite of its extra price.

The use of square sets is advantageous in that repairs to the lining of chutes can be readily effected. On the British mine these chutes are built of 10 by 10-in. timber, having joggled ends, the idea being that the

timber will last out the stope. Against this, there is greater wear on the timber when the grain is at right angles to the falling ore.

With square sets a convenient construction is afforded for the provision of a ladderway alongside the chute, which, besides being useful for traveling, is of great assistance in case the ore in the chute “hitches up.” The advocates of chutes without ladderways claim that the material can generally be started with the aid of a cannon, but this involves a certain amount of delay, especially as the cannon is not always effective.

On the South mine, where the ore occurs to a greater extent in pipes or chutes, circular ore chutes built up in sections, as shown in Fig. 15, are successfully used. The timbering is thickest, of course, near the bottom, where the wear is greatest. An essential condition for the satisfactory use of these circular chutes is that the pressure be approximately equal on all sides; their use, therefore, in ground subject to much pressure from the hanging wall, is prohibited.

Prevention of Underground Fires

The leading mines, where considerable quantities of timber are used underground, have complete installations of fire-service mains, generally 1¼ in., throughout the various workings, with tanks underground, placed, say, every 300 ft., to avoid excessive pressure on the mains, and kept full by means of ball float-valves.

The local experience with regard to underground fires has been that the only hope of subduing them is by the prompt application of a small quantity of water under pressure, and therefore the lighter the gear the more likely it is that the fire will be subdued before it reaches portions of the workings that might quickly become inaccessible through the burning out of the timbering. For this reason, ¾-in. hose in 60-ft. lengths, placed in the levels every 200 ft., is used on the Proprietary mine.

With a view to preventing the spread of fires which may obtain too

strong a hold on square-set stopes to permit extinction without flooding the workings (which is sometimes impracticable), the Proprietary Company has made a practice of forming, at various portions of the workings, barriers to the progress of fires by having all timber connecting adjoining sets replaced with iron or steel spreaders, generally railway rails; and special plain castings (Fig. 15) are placed at the junction of the set timbers to hold the end of rail in position and prevent them entering the timber by increasing the area of base. If these barriers are constructed while ordinary stoping proceeds, very little added expense is incurred, as there is generally a stock of old rails available at low cost.

The various mines have provided themselves with different forms of smoke-jackets to enable the wearers to enter workings containing an irrespirable atmosphere, goggles being also provided to protect the eyes from smoke. Among those employed are the “Proto” and “Pneumatogen” types, using compressed oxygen, and the “Aerophor” using liquid air; the last named has only recently been introduced at the North mine.

This apparatus is looked after by the fire station and ambulance staff, resident at each large mine, under the supervision of the underground manager, and in addition to the members of these staffs the shift bosses receive periodical practice with the breathing apparatus. Each of these mines possesses pulmotors, in the use of which the ambulance staff and others are trained, so. that respiration can be most effectively restored in cases of “gassing,” etc.

Underground Staffs

The problems to be faced in the working out of the large bodies of ore occurring in this district call for the application of scientific principles to a much greater extent than is the case with narrow lodes.

In the earlier days when the exploitation of the orebodies was not systematized to the extent that now obtains, creeps due to the collapse of stopes were frequent. On this account it has been the practice for a considerable number of years to put in charge of the underground work an officer who has received thorough scientific training as a mining engineer, combined with sufficient, practical experience. In some cases this consisted of 18 months manual work in various capacities underground, etc., in other cases, three or four times this length of service as underground surveyor. This officer usually has a similarly trained assistant, or an understudy is being trained while on the underground survey staff.

Under the underground manager and his assistant, there are day foremen, as many as necessary, according to the extent of the workings allotted to him. To these men fall the duties of letting all the ordinary ore-breaking and development work contracts, besides looking after the general safety of the workings, arranging for the filling of stopes as required, and many other duties that it is not necessary to particularize.

Next, there are in the largest mines assistant foremen who are competent to take the place of the day foreman in case of his absence and these men follow each shift, the one on the day shift generally having charge of the wages-timbermen who, with few exceptions, work on day shift only. Finally, there are the shift bosses who are picked men drawn from the ranks of the miners and who may ultimately become foremen. In larger mines there is a separate boss in charge of the truckers, both on ore and in filling stopes—the ordinary boss confining his attention to miners’ work.

An important part of the duty of shift bosses is to see to the safety of the backs, etc., of the stopes. Familiarity with danger too often leads . to contempt of it on the part of the miners, and consequently to accidents.

Timekeepers check the attendance of the workmen when entering and coming up the shaft, and make up distribution sheets showing the branch of work against which their earnings are to be charged, i.e., stoping, development or preparatory work, repairs of different kinds, etc., as the case may be.

The contracts are let as a rule to parties of six men, i.e., two per shift; but sometimes this number is doubled especially if separate chutes are not available. As a general rule, a small party works more amicably than a large one, and for this reason is preferable. The earnings are made up and distributed to the various individual members of the contracting party by the companies pro rata, according to the number of shifts worked, thus relieving the party of the necessity of accurately apportioning the proceeds of the contract.

Cods

Complete cost sheets are made up showing the cost per ton of the various items of expenditure, there being subdivisions into: (1) Labor; (2) Stores (including coal and water for power and all supplies); (3) Miscellaneous, and (4) Special expenses not directly chargeable to ore raising, but which must be included in the total cost.

At the Proprietary mine, complete costs are worked out and made available to the management two days after the close of the week; and, in addition to the complete weekly costs, daily cost sheets on somewhat less elaborate lines are also made up; most of the items in these daily costs are accurately stated, but in a few instances where it is difficult to obtain the daily quota, average figures are used.

The total cost of mining in the district varies considerably according to the nature of the ore and its mode of occurrence—whether in large regular masses or separate veins, or in pillars left between old stopes, or in isolated bodies. But, in general, it may be said that the costs range from 15 to 20 shillings per ton when, as during 1914, the earnings of miners on contract averaged about 17s. 6d. per 8-hr. shift.

In conclusion, I wish to acknowledge the assistance rendered by the underground manager of the Proprietary mine, and his assistants (Messrs. Slee and Coldham), and also the courtesy shown by the managers of the various other mines in facilitating the preparation of this paper.