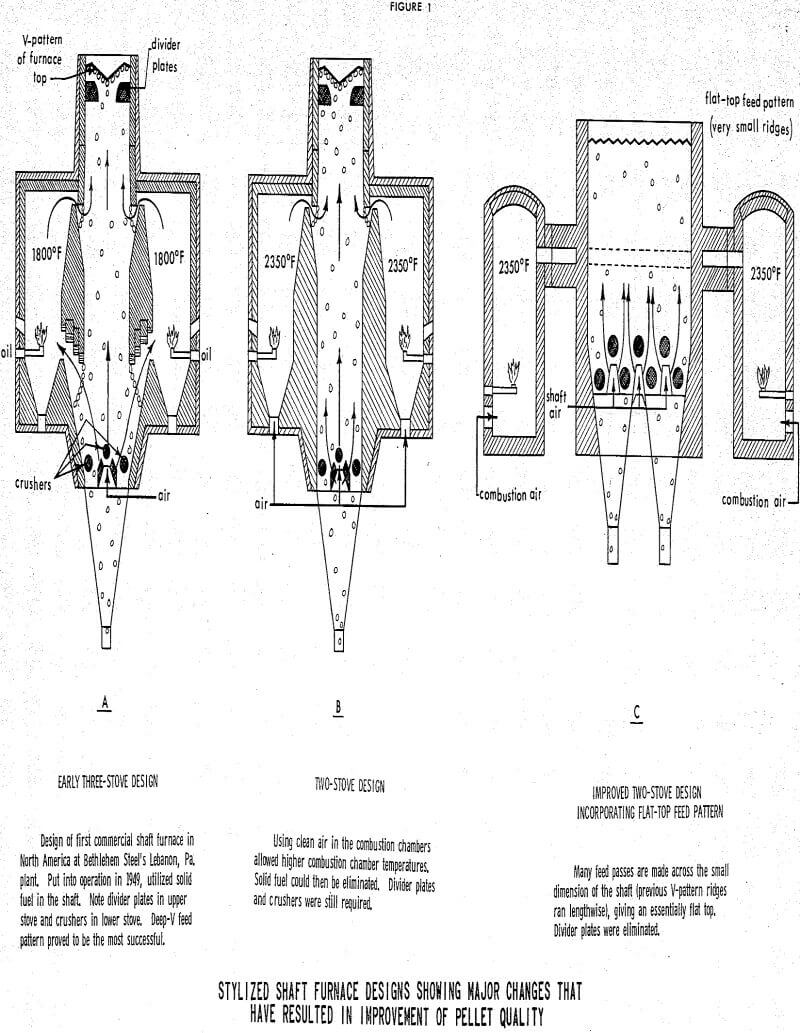

The use of solid fuel in shaft furnaces to indurate iron ore pellets was originally considered a necessary evil, which the industry worked long and hard to eliminate. Since then changes have taken place in furnace design and operating practices that have led us to our suggestion that solid fuel additions could again be used. In essence, what has happened is that the developments which made it possible to operate without solid fuel have also created new operating conditions favorable to the effective use of solid fuel.

The early furnaces, often called the “three-stove” design, required solid fuel, because it was not possible to add adequate heat to the process through the combustion chambers. Preheated air passed from the shaft, was heated in the combustion chambers, and reentered the shaft. This arrangement had two disadvantages:

- Poor control of the air flow through the combustion chamber produced an uneven distribution of air in the shaft, thus causing zones of hot spots and clustering of the pellets in the shaft

- Temperature in the combustion chambers was limited to a maximum of about 1800-1850 F, because a higher temperature caused the dust contained in the preheated air to plug the reentry ports to the furnace.

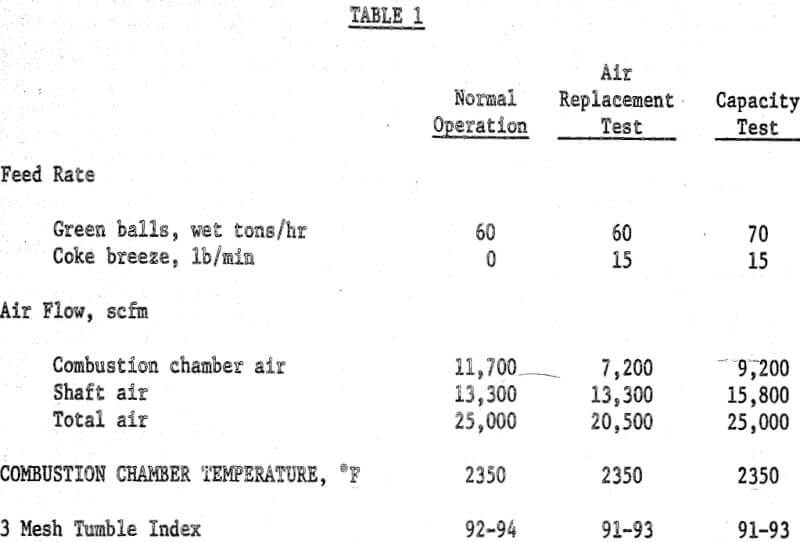

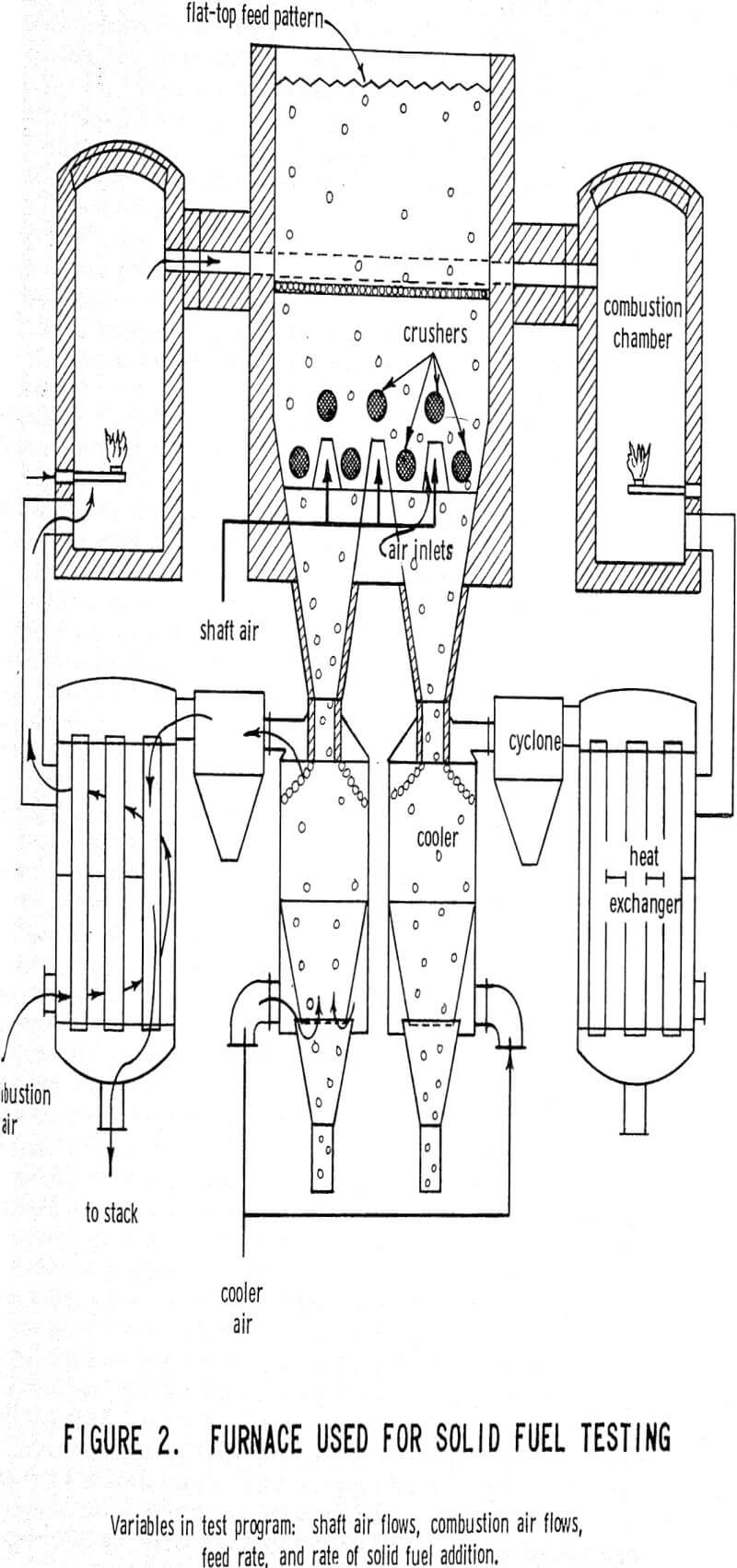

The output capacity of a shaft furnace in operation today is generally limited by the amount of air supplied by the blowers installed on the furnace. Furnace capacity cannot, however, be indiscriminately increased by simply increasing blower capacity, because major increases in air volumes to the shaft are not desirable. Increased velocity in the shaft increases the danger of furnace eruptions, which, in addition to being an operating hazard, can cause a decrease in pellet quality and furnace efficiency.

The principle behind the successful use of solid fuel is simple. Consider first the induration of magnetite. As the furnace feed rate is increased, the air introduced into the.bottom of the shaft for coolings and heat recuperation is increased in proportion to the increase in feed rate. As a result, there is no increase in pellet discharge temperature.

With this method of controlling the heat balance, it becomes possible to indurate hematite or mixtures of hematite-magnetite at the same rate as a 100% magnetite feed. The exothermic heat of reaction of a ton of magnetite concentrate is approximately 400,000 Btu. It is zero for hematite. If 400,000 Btu of solid fuel are introduced into the shaft along with each ton of hematite processed, the heat potential of the combination is equivalent to the heat potential of magnetite and does not affect the thermal balance of the furnace. Mixtures of hematite-magnetite require solid fuel additions, depending on the ratios of magnetite and hematite in the furnace feed.