Table of Contents

The pelletizing process for low grade iron ores has undergone continual changes since its inception over twenty years ago. These changes have necessitated filtration equipment changes in order to produce a product suitable for balling. With modern techniques it is now possible to produce pellets of 68% Fe from ores containing as low as 26% Fe. Low grade ores require fine grinding to liberate impurities. This shift to finer grinds over the years has necessitated major changes in the filtration steps.

The Pelletizing Process Development and First Generation Filters

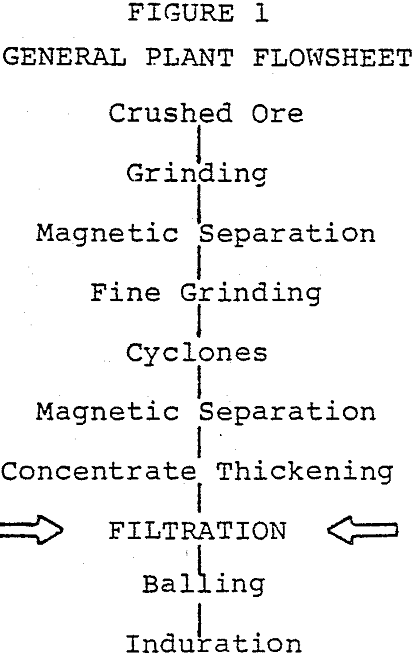

In the early years of pelletizing, many process variations were used in order to produce a marketable product. Today some variations still exist on a plant to plant basis to best accommodate a particular type ore. The crushed ore is coarse ground and followed by a step to remove the rock silicas. Magnetic cobber separation is generally used for magnetic ores. Further fine grinding in rod and ball mills followed by further separation and classification generally produces the feed for filtration. Preceeding the filter step is a concentrate thickener to increase the filter feed concentration to between 55 and 65 wt%.

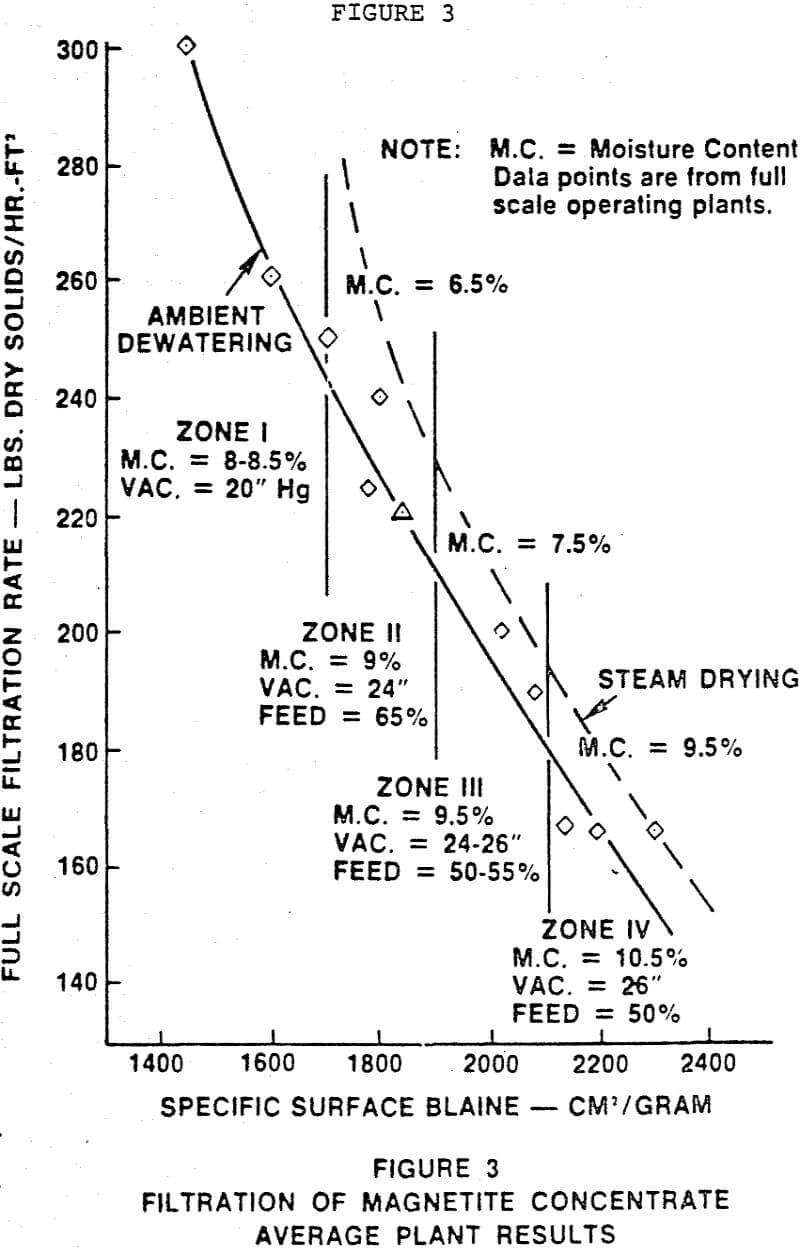

In the early developmental stages of iron ore beneficiation, relatively coarse grinding was used and the Blaines of the concentrates usually ranged from 1300 to 1600 cm²/gram. Although drum filters were briefly used for early dewatering in order to compete with direct shipping ores, capital operating costs were reduced by employing the disc filter.

Cake moisture content is one of the critical factors of the balling operation. To produce a proper green strength ball that fires properly, moisture content must be relatively low and within a narrow range. Since the filter speed controls the cake moisture content and production simultaneously, filters are operated at speeds which allow enough dry time to produce the desired cake moisture. Increasing the rotational filter speed reduces dry time and produces higher cake moistures.

Process Optimization and Second Generation Filters

In more recent times, with the requirement of high pellet quality, most of the plants are now operating at finer grinds than the original design basis. This finer grinding has produced Blaines ranging from 1600 to 2100 cm²/gram. The finer grinding acts to reduce the form filtration rates while raising cake moisture contents at comparable dry times and conditions.

In order to achieve a suitable balling moisture at the higher Blaine surface ratings, vacuum levels during the filter cycle were increased to 24 to 26 inches of mercury. This increased driving force reduced cake moistures as well as helping production rates.

Although cake cracking is not restricted to a certain grind, the tendency is more prevalent at higher Blaines. Plants with ores which showed cake cracking during the cake drying segment increased vacuum pump capacity in order to maintain a higher vacuum level to keep moistures down.

Steam Drying and Third Generation Filters

Low grade hematite ores are also beneficiated for pelletizing, but normally a flotation process is employed. These concentrates usually exhibit lower filtration rates at the same Blaine as a magnetite concentrate. Some hematites, in order to achieve pellet purity, have been ground to Blaine values as high as 2500 to 3600 cm²/gram. The fine grind requires special filtration techniques to achieve a moisture content less than 12% for good balling. Special techniques have been developed to reduce moisture contents.

Flocculation is also used effectively to produce flocculi from the sub-micron slimes and thereby enhance filtration rates. Usually pH modification is necessary to achieve proper flocculation. Even with the above methods, grinds are often so fine that some type of post-filtration drying step is required. Due to the thixotropic handling characteristics of the wet filter cakes, the obvious solution is to continue drying on the filter disc.

High Performance for Fourth Generation Filters

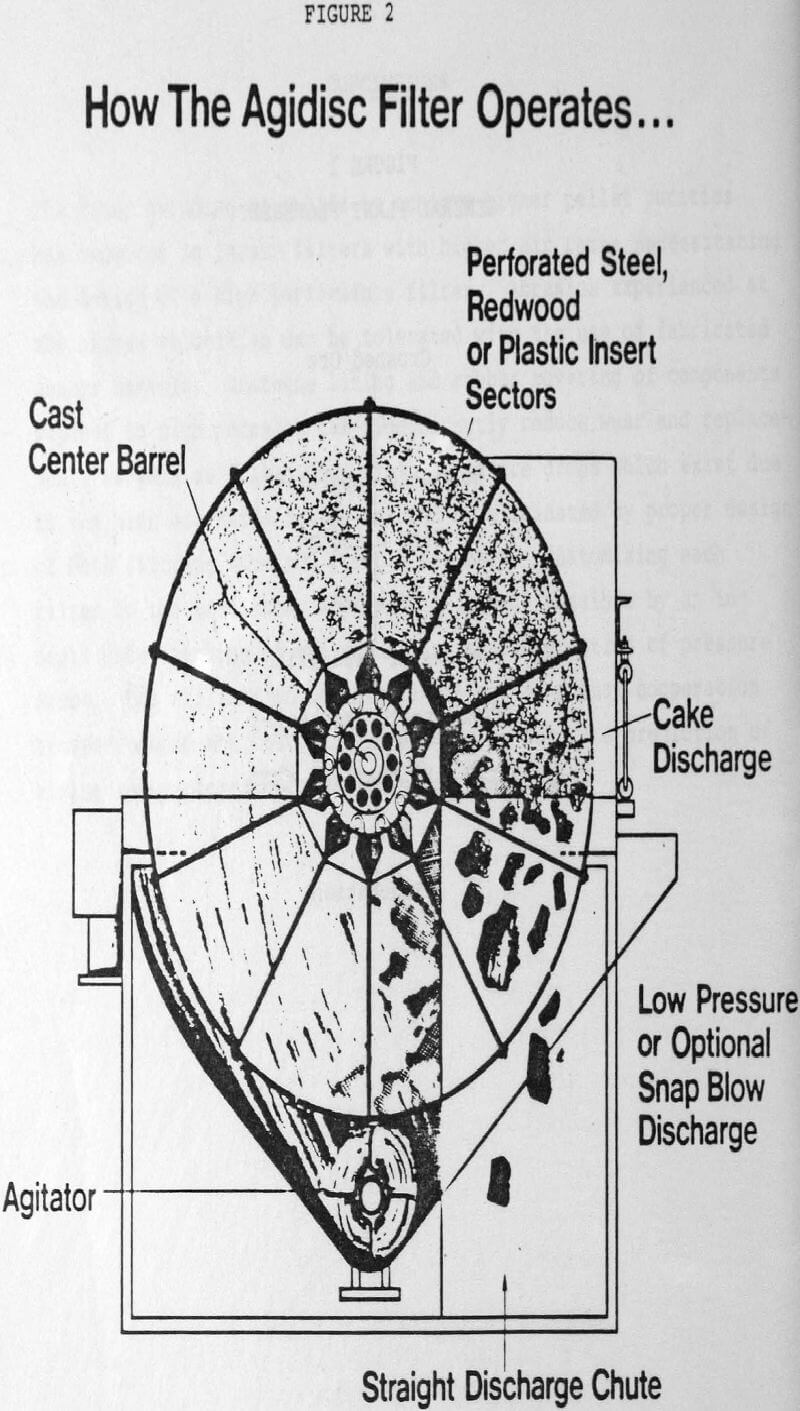

The unique nature of the filtration requirements for the iron ore industry has promoted research to manufacture a more durable high performance unit for this application. The shift to finer grinds accompanied by larger filters with high air rates require changes to minimize the abrasive characteristics of the slurry. In addition, the extremely high air rates produced pressure drops within the filter, which, with proper design, can be eliminated.

Figure 6 outlines those changes made to improve the maintenance and reliability of the filter. Abrasion, the major cause of wear, is the result of two conditions. These are high air velocities coupled with a high slurry solids content. Normal filtrates should be less than 1 wt% solids and preferably 0.5 wt% or less. However, when a hole develops in the filter media, filtrate solids concentrations will increase to well above 1 wt%.

Usually, all errosion failures occur beneath the ferrule location. To further reduce abrasion in the event of improper sector sealing, a urethane liner is poured into the bottom of the filtrate tubes. This very significantly extends the tube life.

With increased filter size and higher air rates, abrasion to the valve increased. The primary wear area occurred as the instant filtrate pours from the sectors and is carried down the filtrate tube to the valve. The combination of solids coupled with the high air velocities again were the primary contributions to abrasion. Rubber lining of the valve head in the high wear portions has eliminated the problems in this area, extending valve life significantly.

Filter Hydraulic Studies

Although filter hydraulics appear to be straightforward in nature, an in-depth study reveals the opposite. A two year study has allowed an exact determination of the location and nature of Agidisc filter pressure drops. This data is now computerized. This computerization allows the design engineer to select the exact combination of ferrule size and filtrate tube size which optimizes performance, while minimizing cost to the customer.

During the cake formation portion of the filter cycle, the sector is submerged and very little pressure drop exists. This is consistent with calculations which show the sector never completely fills with filtrate during this phase of the cycle. The slight pressure drop, which does exist during cake formation, is most likely due to air leaks which were present in the filter coming from either poor ferrule connections or improperly sealed bags.