Table of Contents

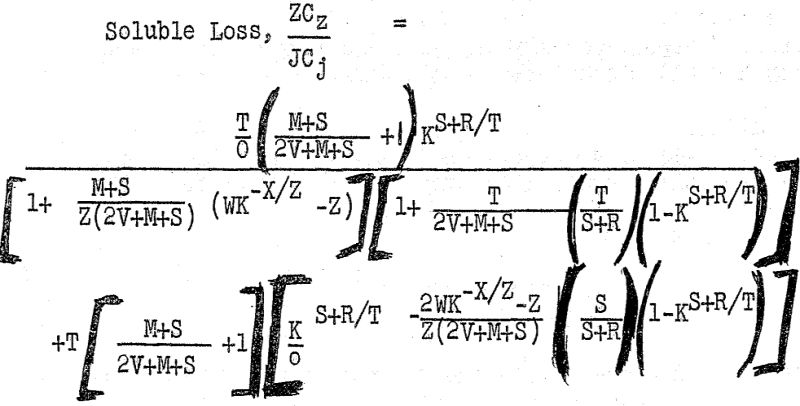

The operation of a series wash thickener-two stage filtration circuit determines the soluble loss in many hydrometallurgical operations. A study of this circuit yielded expressions which permit calculation of soluble loss for almost any condition of operation. The soluble loss over a range of the circuit variables is presented to illustrate and evaluate circuit performance. The interrelation of factors affecting filter performance and some of the wash circuit variables are qualitatively described.

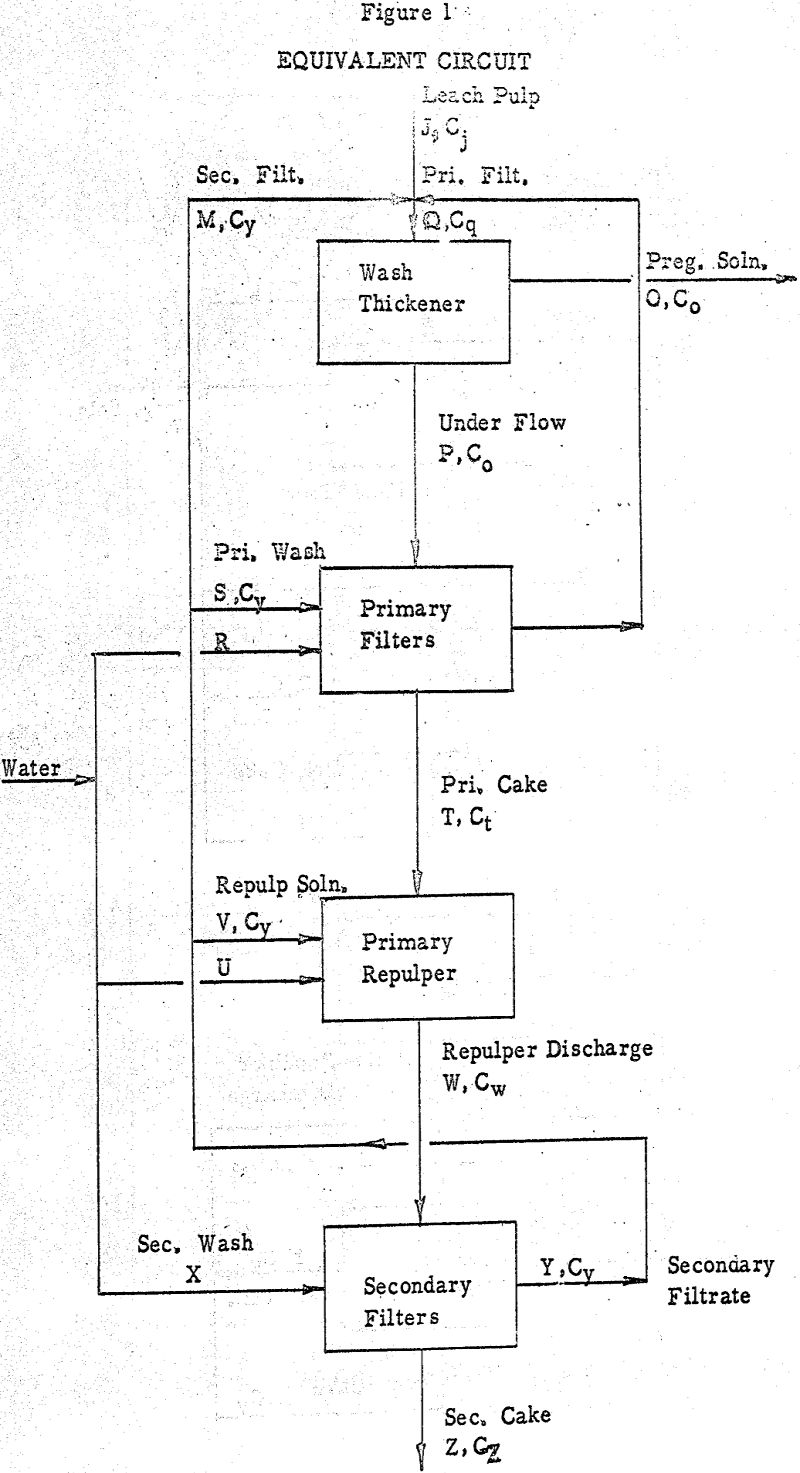

The Circuit

This circuit provides for counter current, cross current or for a combination of countercurrent-cross current operation. The feed pulp stream, J, is intended to include any solution or water, other than primary and secondary filtrate, which enters the wash thickener. Except for filter washing, the operations in the circuit are simple mixing operations which can be described by material balance.

![]()

where E = wash efficiency factor, K = wash inefficiency factor. L = fraction of the original cake liquor remaining in the cake after wash, w/l ratio of the wash volume to the cake solution volume (number of wash displacements).

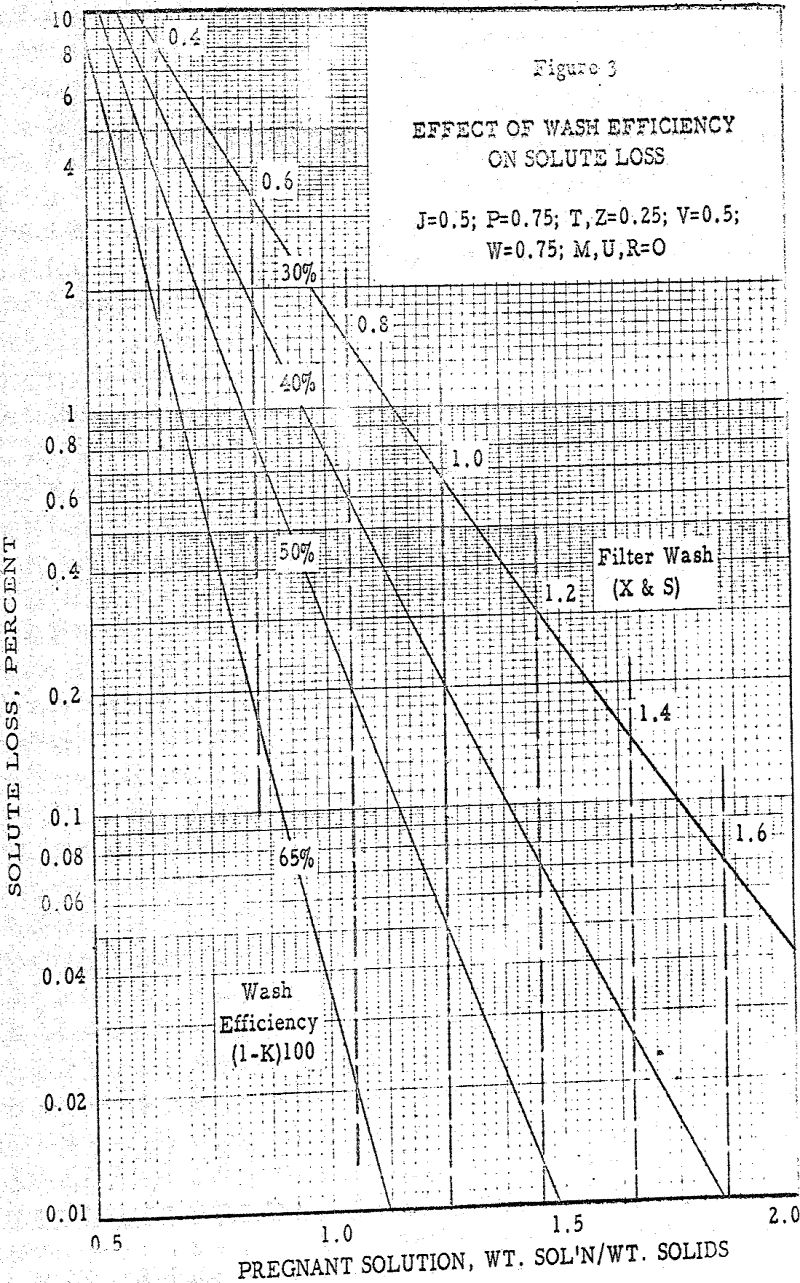

The variables in a “typical” circuit were assumed to have the following values:

Filter wash efficiency factor 0.5 (K – 0.5)

Filter Cake Solution (moisture) 0.25 d.u. (20% moisture)

Leach pulp solution 0.5 d.u. (66.7% solids)

Wash Thickener underflow solution 0.75 d.u. (57.1% solids)

Repulped pulp solution 0.75 d.u. (57.1% solids)

All other streams (except filter-wash = 0

In this case, the amount of cake solution was varied from 0.22 to 0.30 with all other variables, except filter wash and pregnant solution, constant.

In washing theory, cake solution is that present in the cake just prior to washing. In practice, it is usually considered that present at cake discharge. It is probable that the cake moisture is not identical in both cases. The two different cake moistures could have been included in the circuit equation, but this complication was not warranted because an “apparent” wash efficiency factor can be used.

For the “typical case” increasing the filter wash by 0.1 tons per ton ore, which increases the amount of pregnant solution by an equal mount, results in a soluble loss decrease by a factor of 0.47 (a 53% decrease). The soluble loss decrease with increased wash is more pronounced as wash efficiency factor increases.

Thickener underflow density does indirectly affect the amount of wash applied to the filters as discussed in a subsequent section. If the thickener-underflow is diluted by a wash solution, thickener underflow density does affect soluble loss.

Use of water instead of secondary filtrate to repulp the primary cake decreases soluble loss. However, the secondary filtrate so replaced must be used as an increased primary wash or returned to the wash thickener.

If, on the other hand, the excess secondary filtrate is sent to the wash thickener, the soluble loss will decrease by a factor of 0.75 (25% decrease) for 0.1 ton water to repulp per ton ore.

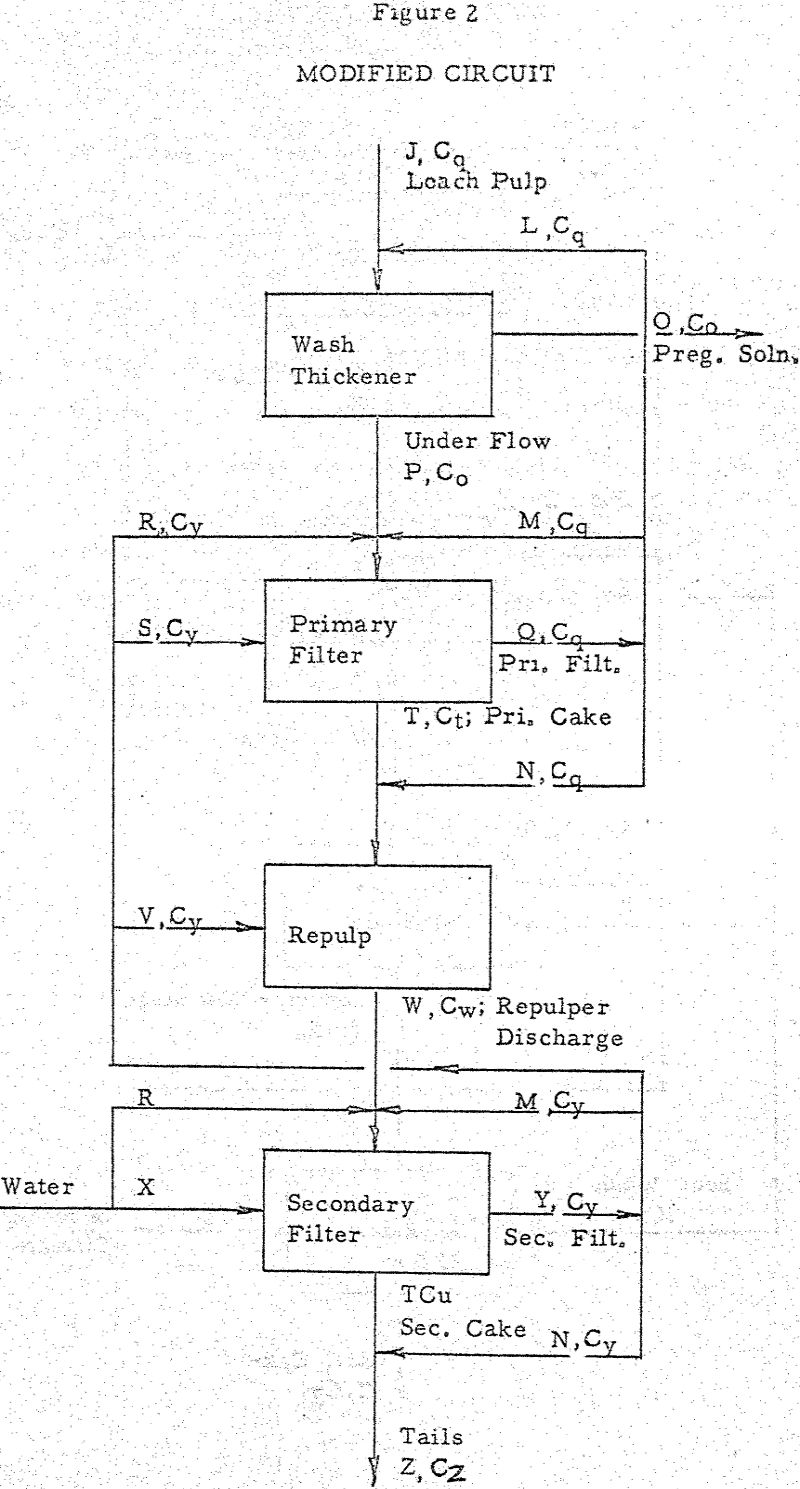

Modified Circuit

The circuit employed in the previous calculations does not allow for “blow-back” or flood washing. Most filters operate with a certain amount of “blow-back,” which is the discharge of solution from the filter drainage deck and pipes during cake discharge. Some filter operators advocate the practice of “flood washing” which usually results in the dilution of the pulp in the filter boot with wash solution and sometimes the discharge of wash solution with the cake.

The corresponding streams on the primary and secondary filters are assumed to be the same size. It should be noted that if front flood washing causes filter wash solution to discharge with the cake, soluble loss is not altered if repulped density is maintained constant. The wash solution is identical to that used to repulp the discharged cake; the net result is to add the repulp solution to the repulper via a different route.

The composition of the liquor “blown back” must lie between two limits. One limit is that the blow-back composition is identical to that of the filtrate. The other limit is that the blow-back liquor has the same composition as that of the corresponding volume of the last increment of liquor drawn through the cake. The first assumes that liquor drawn through the cake during pickup and wash was completely mixed and a portion of this mixture blown back. The latter assumes that no mixing occurred within the drainage deck and pipes.

The case of no mixing can be determined from the previous circuit equation. This case is equivalent to saying that a portion of the wash which went through the cake did not go through the cake and appeared in the cake discharge. If the repulp density is constant then the repulp solution (secondary filtrate) must be decreased by tie amount of blow-back. Thus, the soluble loss is increased by an amount corresponding to the increase in soluble loss due to a decrease in the amount of wash equivalent to the amount of bbw-back.

When a front flood wash in employed on a filter, some wash solution may be discharged with the cake. If the wash solution and the repulp solution have the same composition, as is the case where secondary filtrate is used for both primary filter wash and repulp, the soluble loss is unchanged if the density of the repulper is constant.

This solid filtration rate is increased by increased vacuum, increasing submergence, decreased cake resistance, decreased cycle time, and decreased feed pulp dilution (increased density). Decreasing cycle time means decreased cake thickness which is limited in practice to that thickness which can be discharged.

Filter cycle time, in itself, does not affect amount of wash. However, if submergence is decreased to increase the wash, it may be necessary to increase cycle time in order to maintain a dischargeable cake thickness.

Changing the filter submergence to change amount of wash is difficult unless automatic pulp level control is provided. A better alternative would be to change the filter feed pulp dilution. If this were done with wash solution, soluble loss would be decreased even more because dilution of the feed pulp does almost as much to decrease soluble loss as does increased filter wash.

One of the major objections to flood washing is dilution of the feed pulp and the consequent reduction of filter capacity. In a given plant, this objection is not valid unless the feed pulp is at maximum density and the filters are crowded to ultimate capacity. It has been shown that dilution of the pulp In Itself decreases solute loss and also increases the amount of wash.