Table of Contents

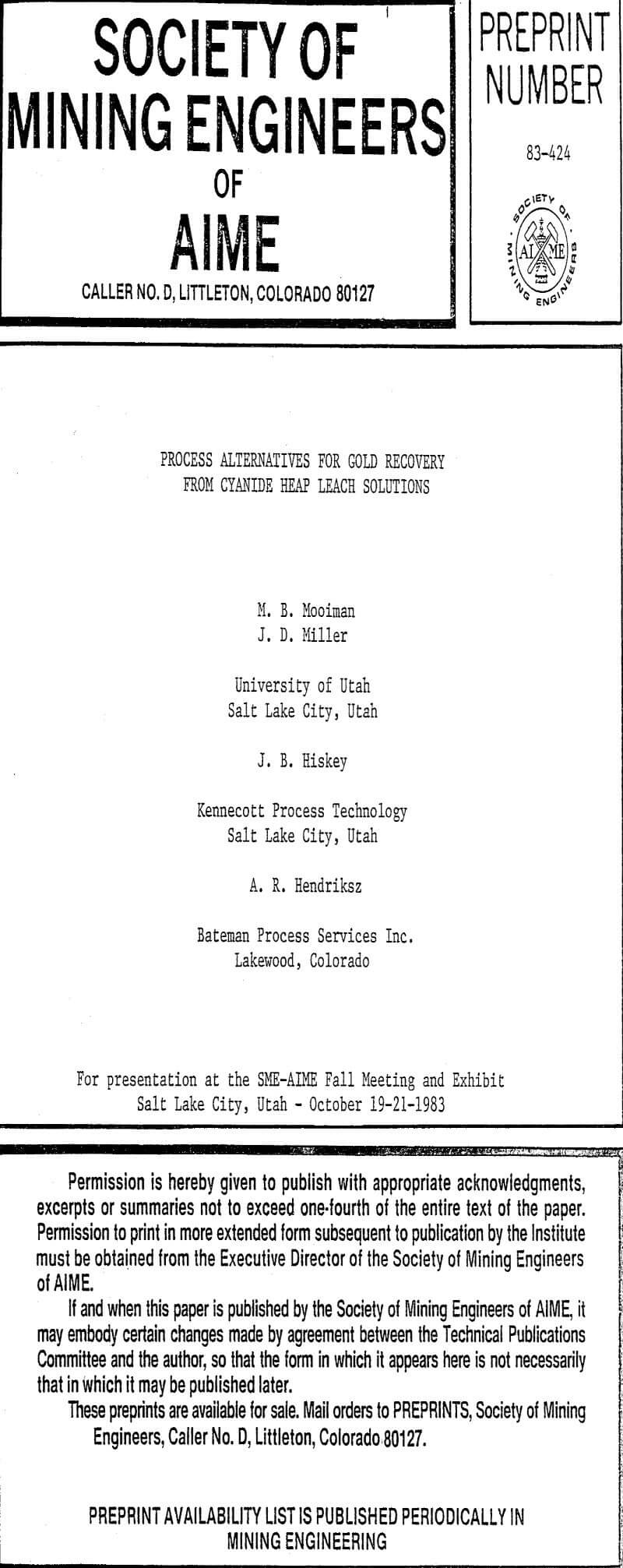

Cyanidation of gold and silver ores by conventional mining and milling techniques has been practiced for over a century. During the past decade, heap leaching has emerged as a viable process for treating certain gold and silver ores. The rapid development of heap leaching for gold and silver ores is largely a result of lower capital and operating costs and faster start-up time than that offered by conventional mining and milling. In general, these features make heap leaching an ideal approach for exploiting either small or large low-grade disseminated deposits of gold and silver considered to be uneconomic by conventional methods.

Technology Status

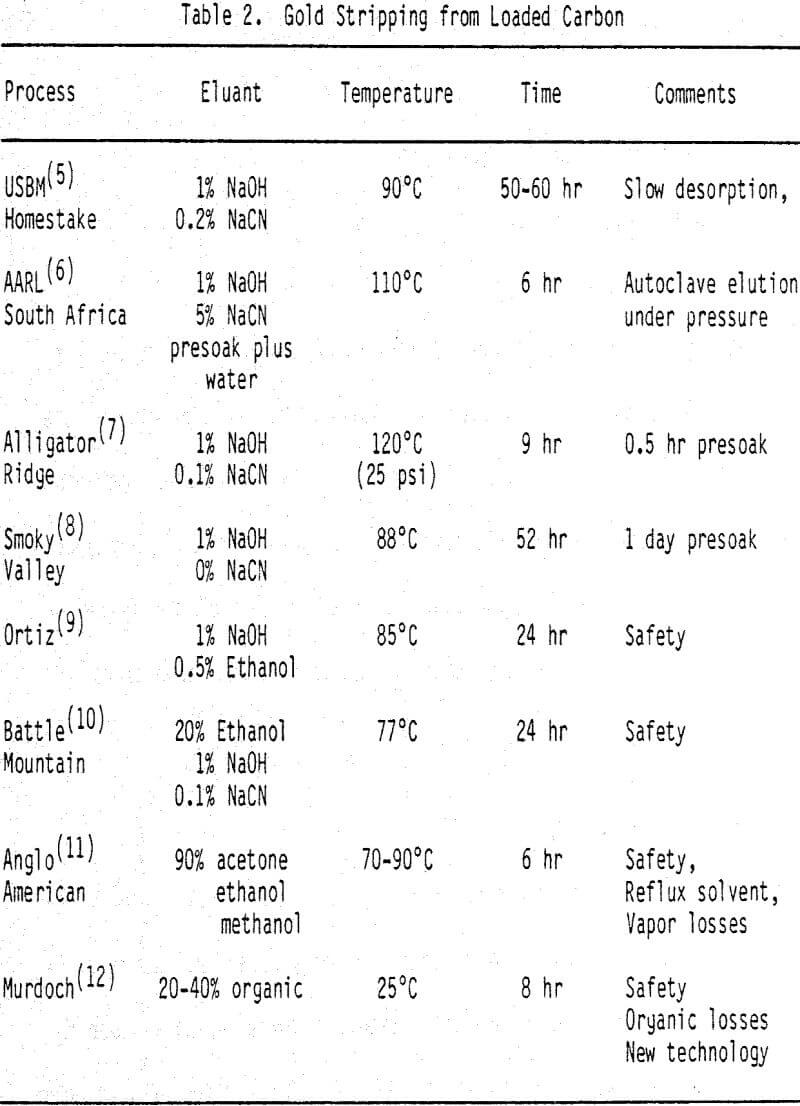

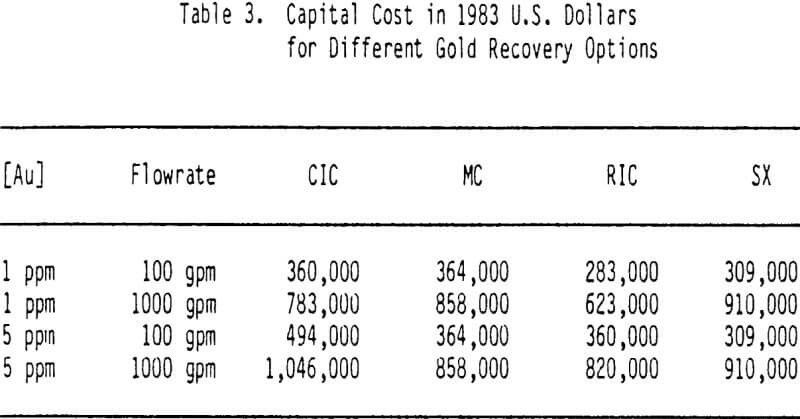

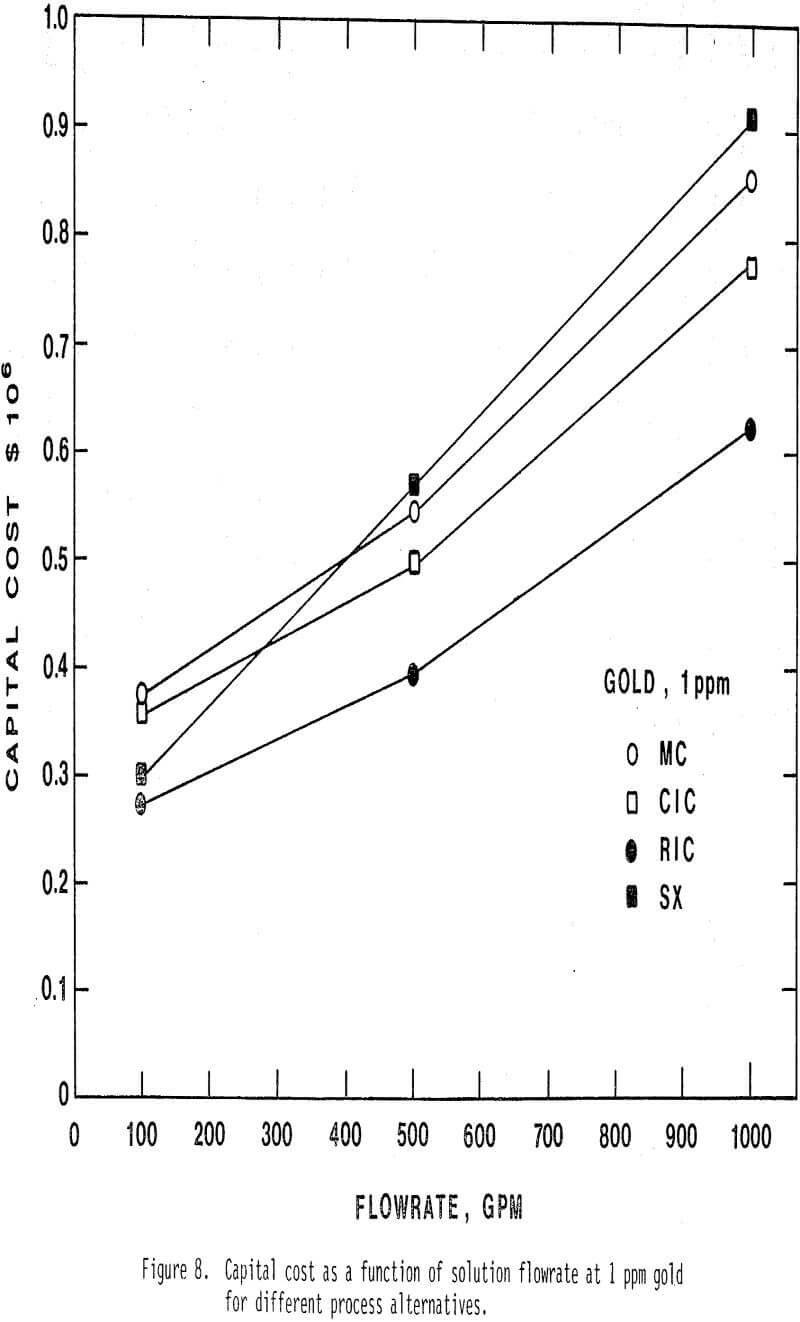

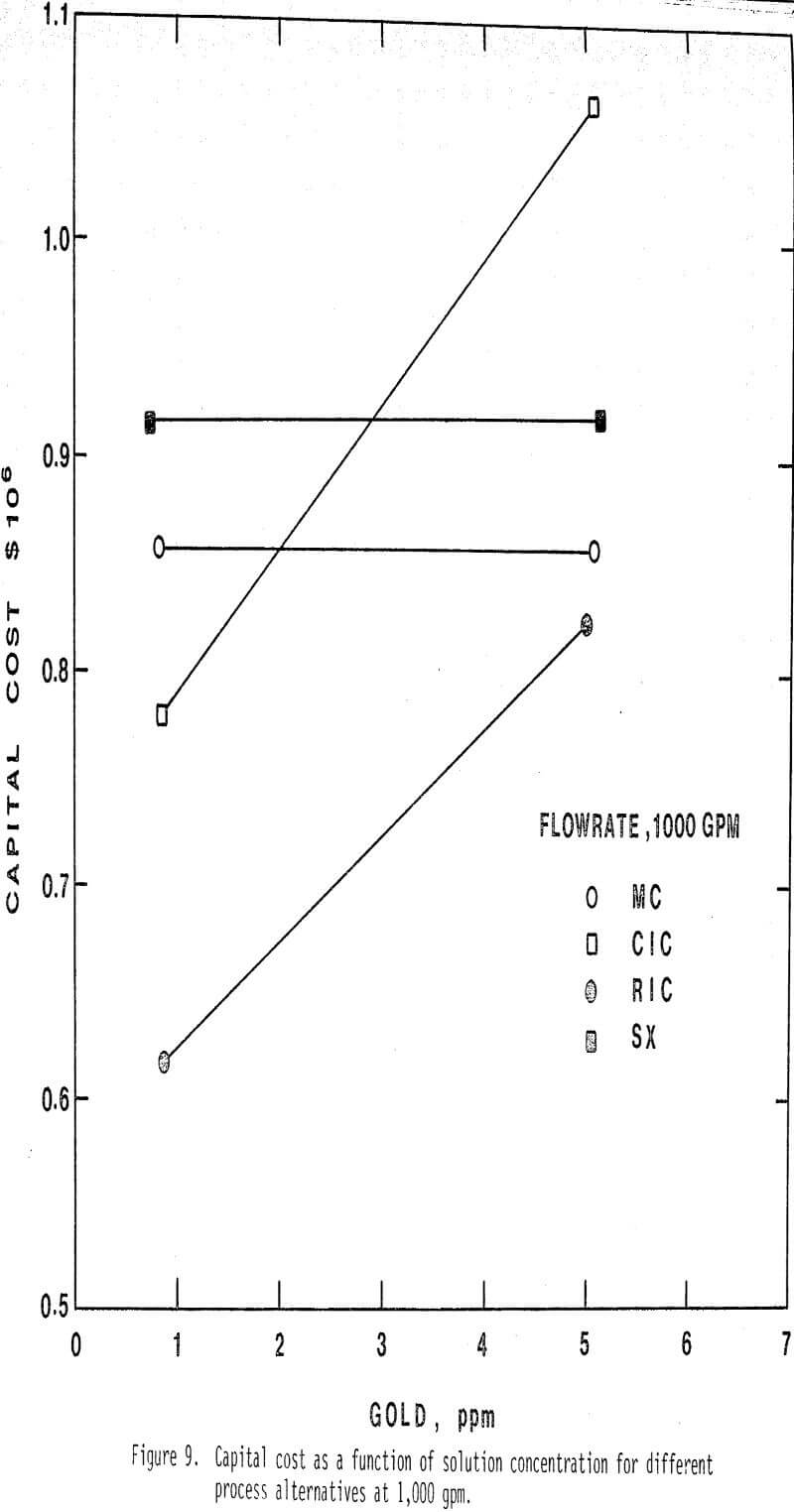

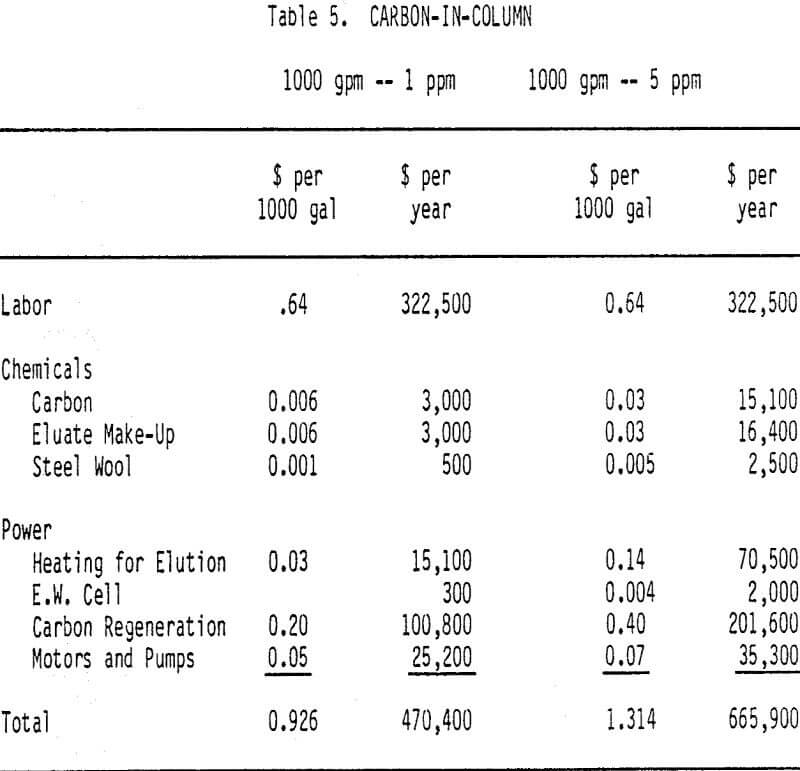

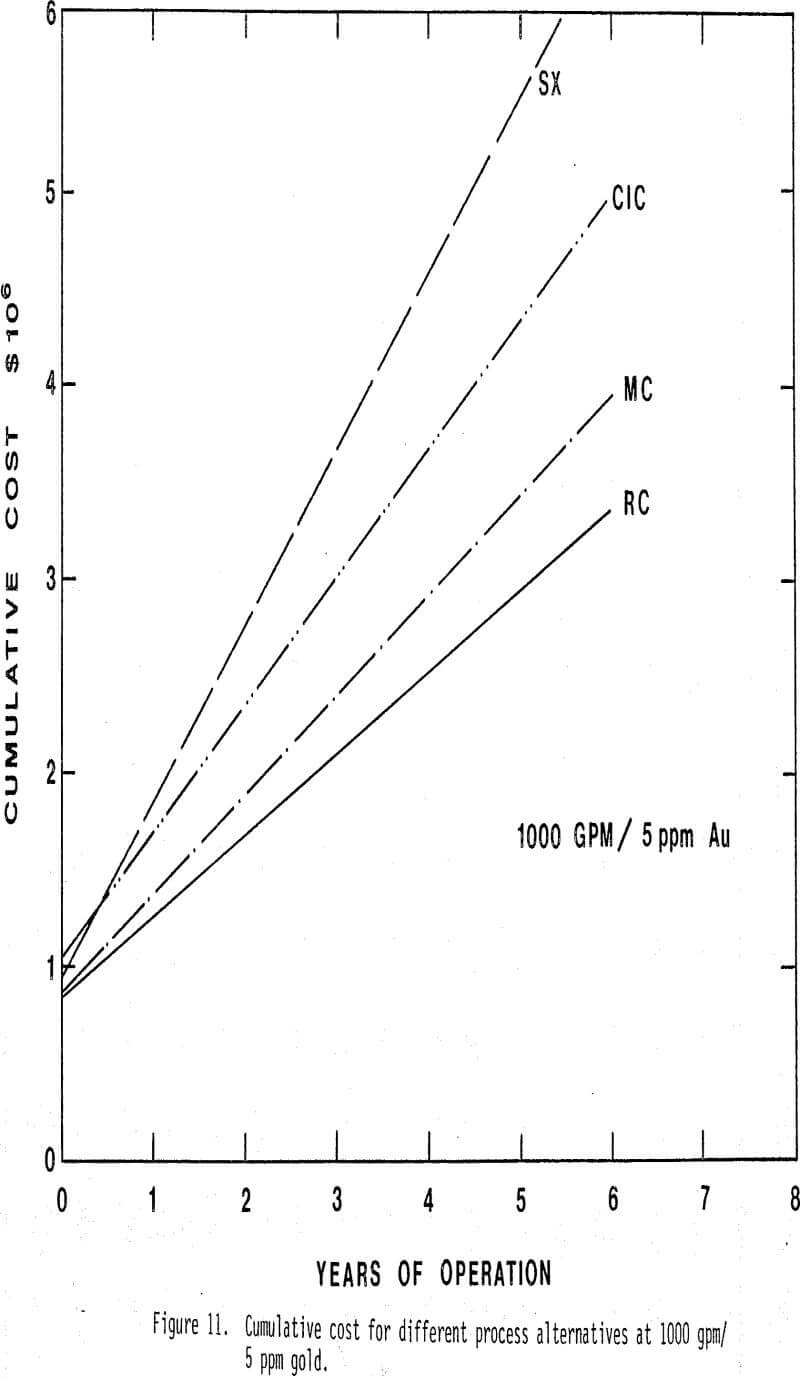

Gold recovery from alkaline cyanide solution is typically accomplished by carbon adsorption or zinc cementation (Merrill Crowe). These and other emerging technologies, particularly resin ion exchange, solvent extraction, and direct electrowinning, are discussed, emphasizing the unique features of each process alternative.

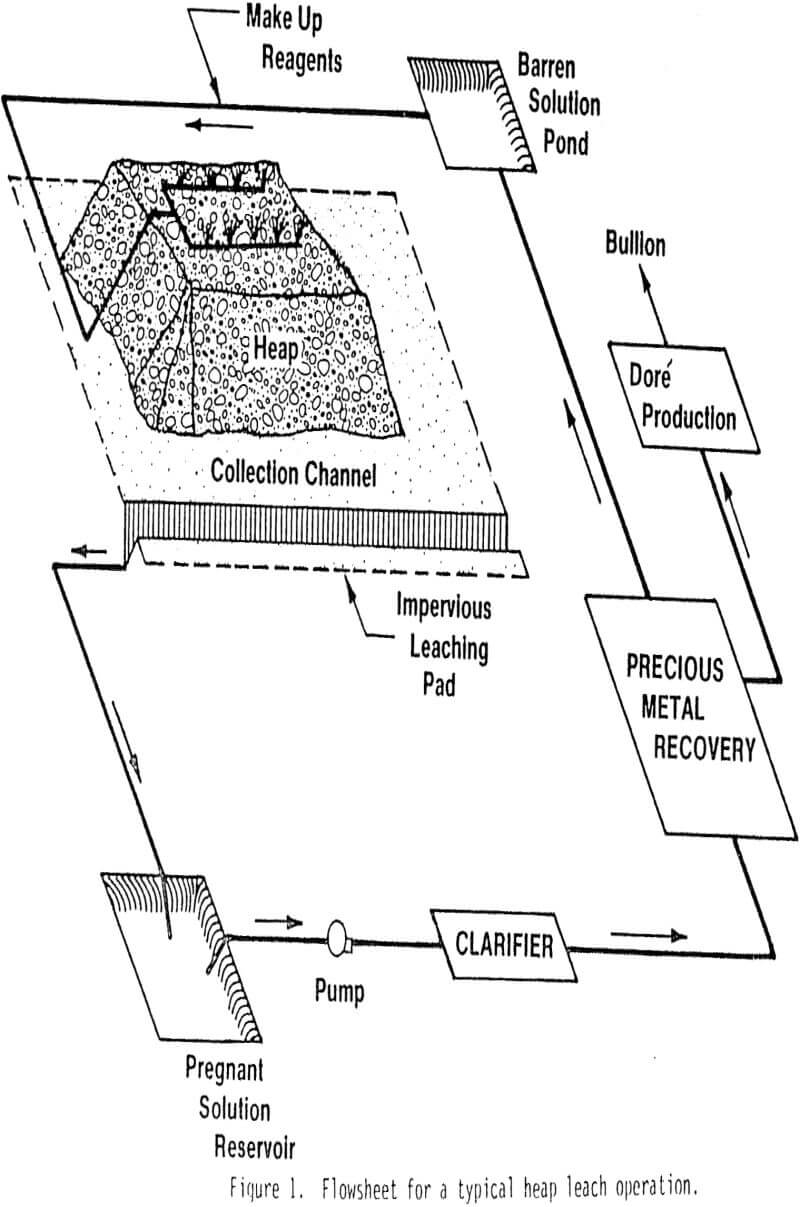

Carbon in Column (CIC)

The essence of the carbon-in-column process alternative is the adsorption of gold from alkaline cyanide solution by activated carbon. For typical carbon-in-column operation, the cyanide leach solution is pumped upward through columns at a flowrate of 15 to 25 gpm/ft², fluidizing the packed bed of activated carbon (16×30 mesh). A carbon-loading level, frequently of 200 oz/ton, is achieved while the carbon is advanced countercurrent to the solution through a staged circuit.

Activated carbon prepared from coconut shells is preferred for gold recovery from alkaline cyanide solutions. These carbons are distinguished by high surface areas (> 1000 m²/g) and a narrow range of pore sizes (10-20 A) and good mechanical strength. Carbon regeneration is required to remove organics and restore the intrinsic chemical activity of the carbon. After removal of carbonate deposits by an acid wash (if necessary), the carbon is activated by a thermal treatment in a kiln at 600-800°C.

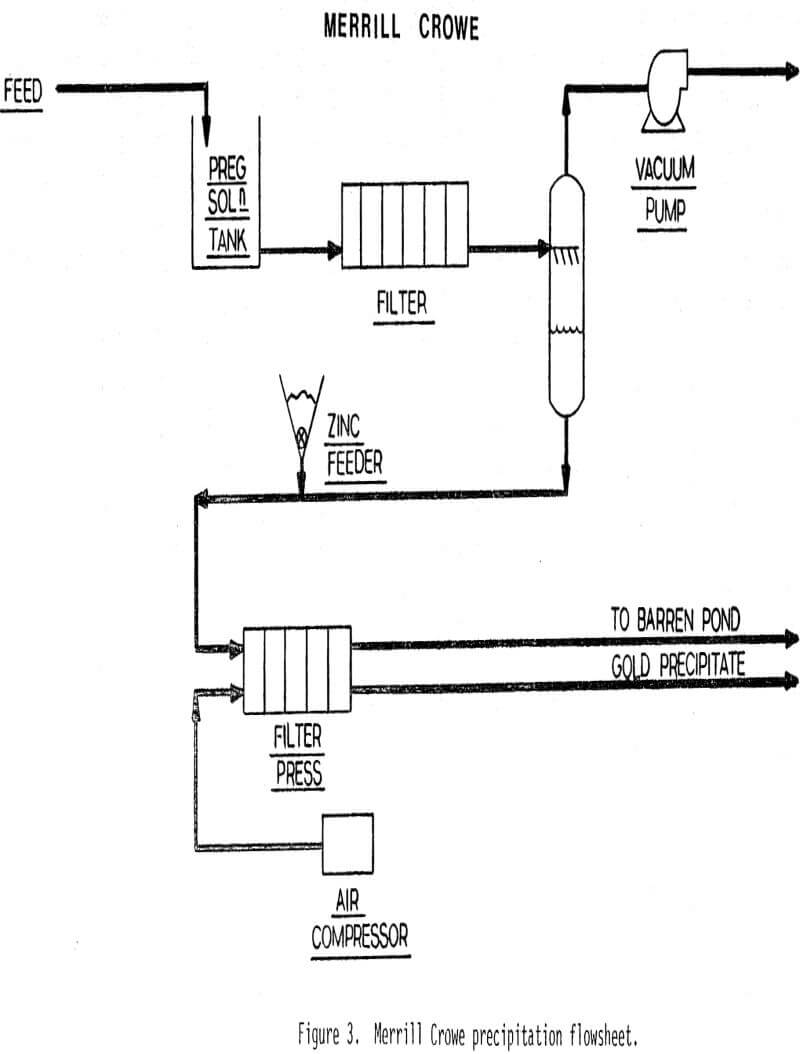

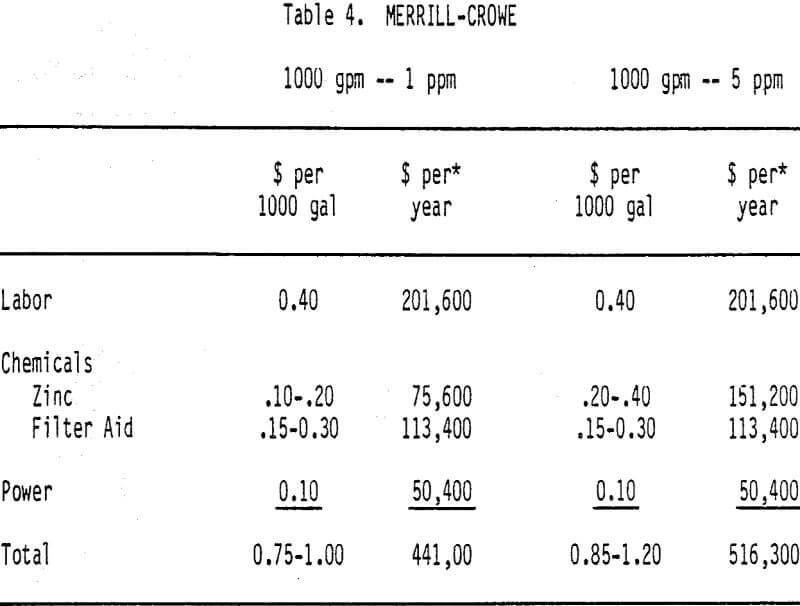

The Merrill-Crowe zinc-dust precipitation process is a mature and well- known technology consisting of solution clarification, deaeration, precious metal precipitation, and precipitate filtration.

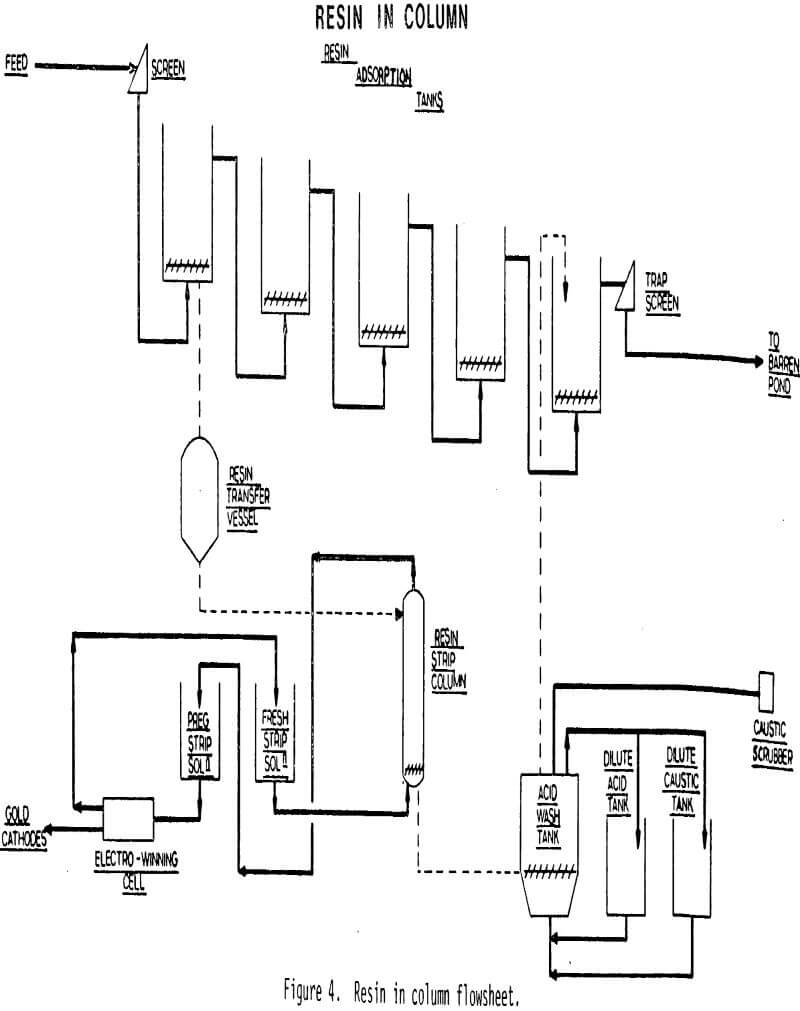

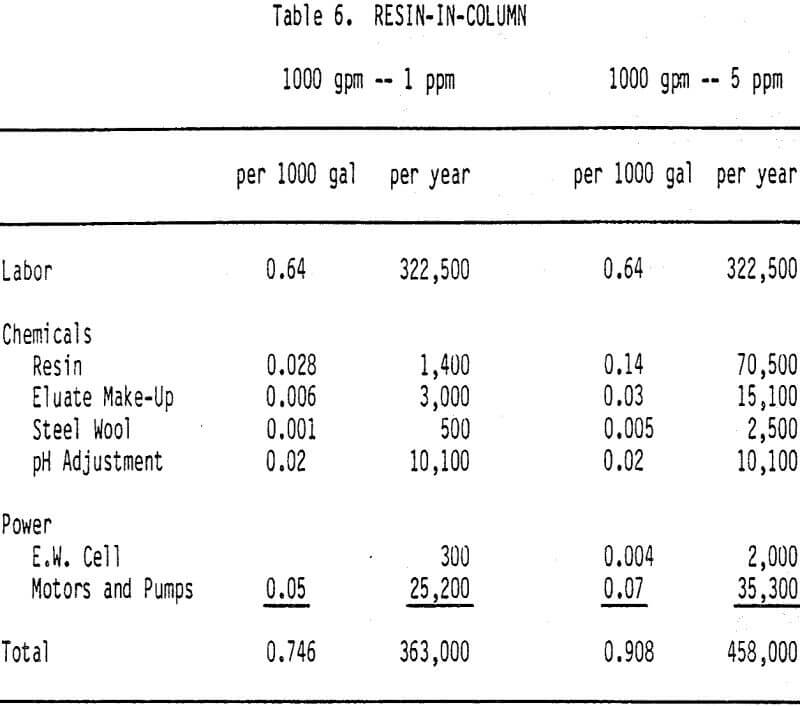

Ion-exchange resins for the recovery of gold from cyanide solution is an emerging technology which is receiving considerable attention. The flowsheet for the resin-in-column plant is similar to that for a carbon-in-column (CIC) plant.

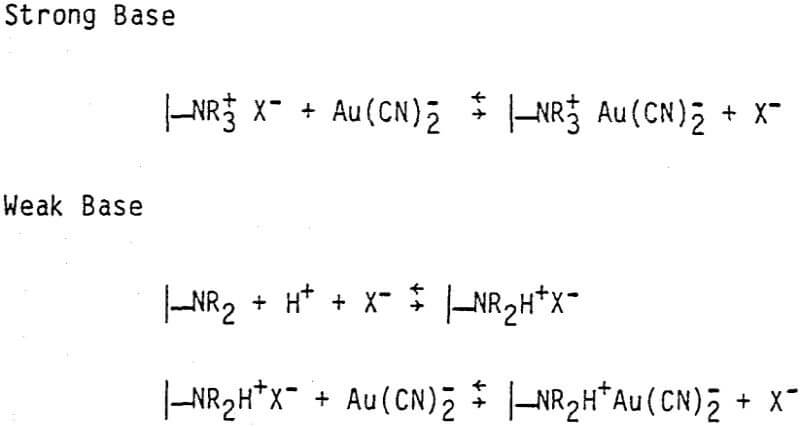

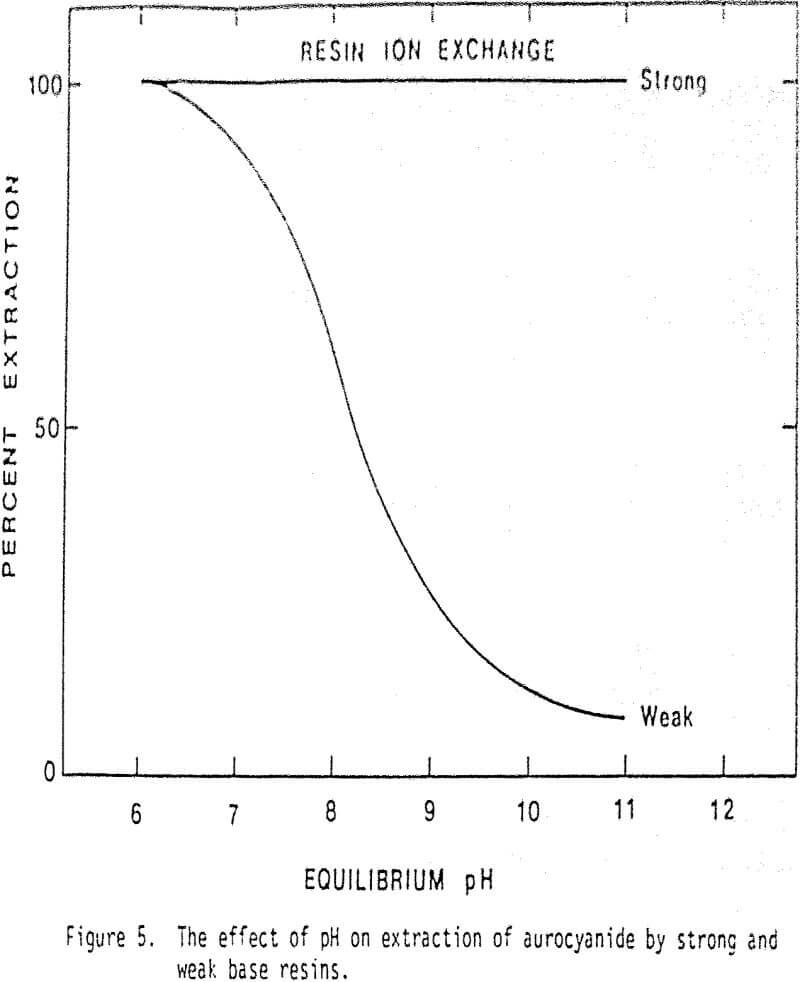

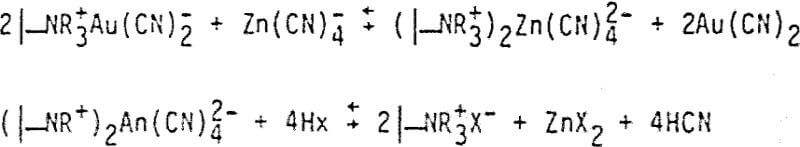

Strong or weak base resins can be used, and the loading reactions for these resins can be described as follows, where represents the polymeric resin matrix.

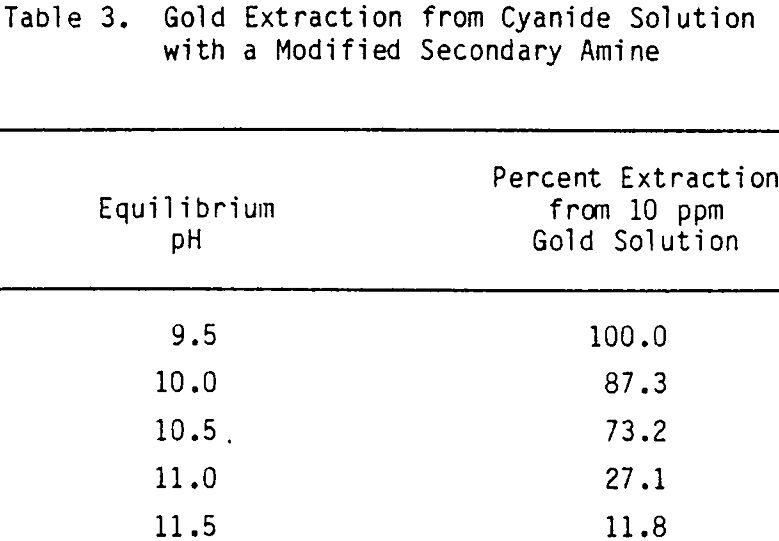

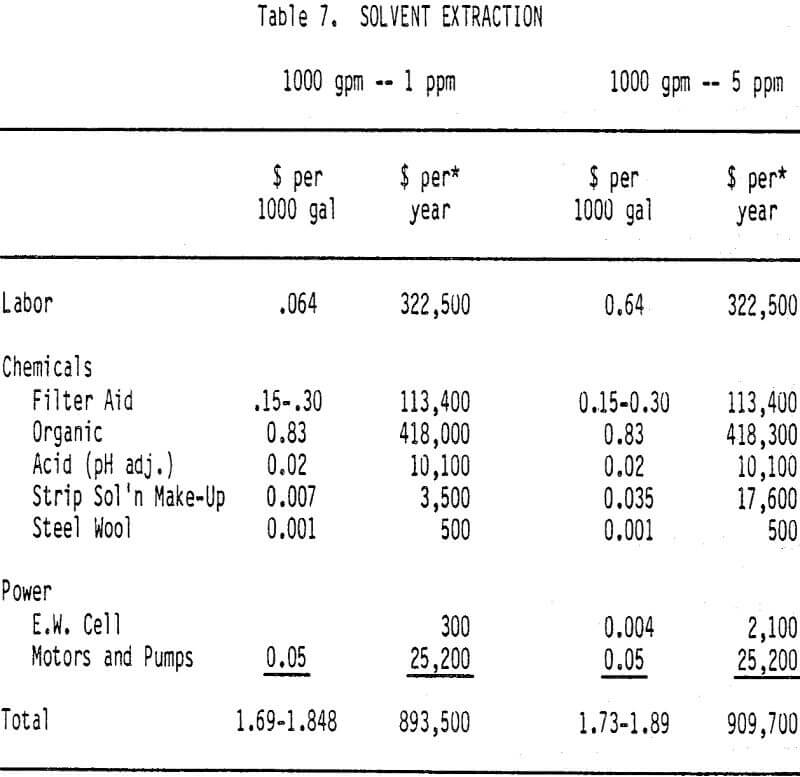

Solvent Extraction (SX)

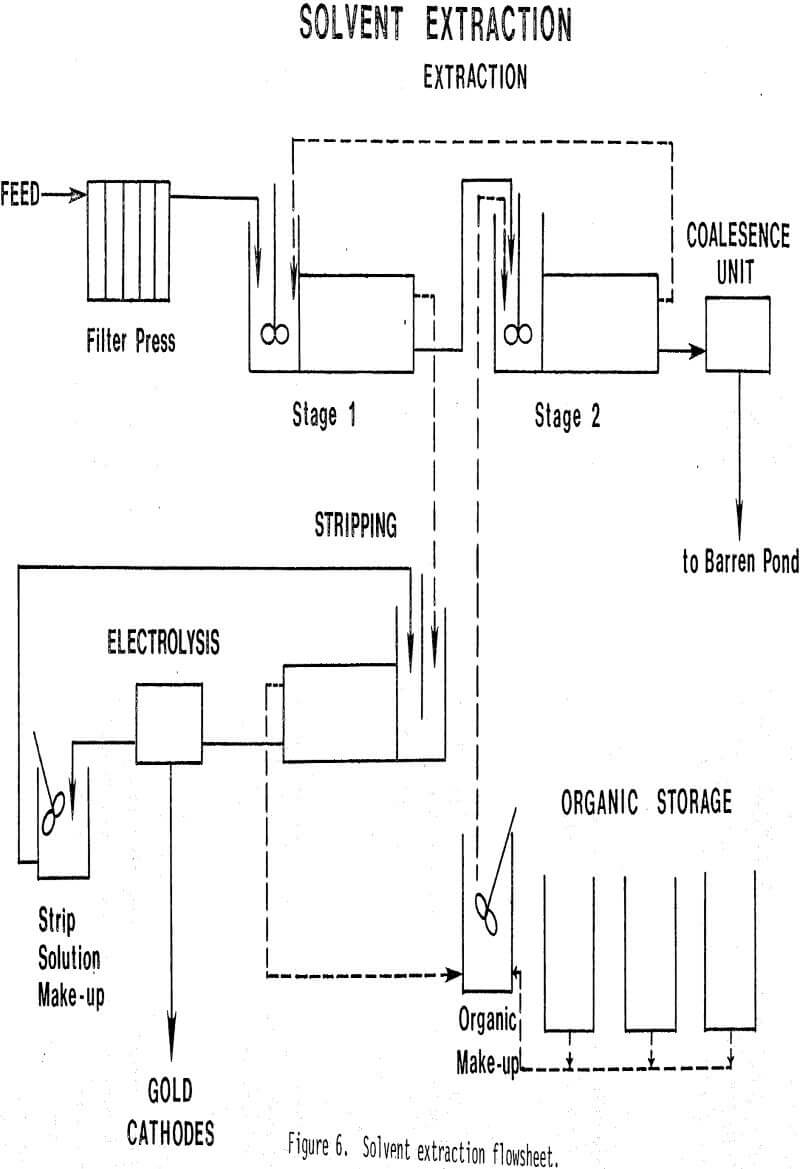

This technology is still in its infancy, a suitable extractant having only recently been identified.Therefore many of the engineering aspects have not been studied and in this paper we shall present a rather simple flowsheet, incorporating the most common contactors, namely, mixer-settlers.

This approach permits at least a first-order evaluation of the capital and operating costs for a gold solvent extraction plant. The conceptual flowsheet is shown in Figure 6 and is described below.

The pregnant leach solution from the heap will have to be filtered if the suspended solids content is too high, in order to avoid excessive solvent losses (by adsorption onto the solid particles). In addition, suspended solids promote phase disengagement problems and the formation of interfacial crud.

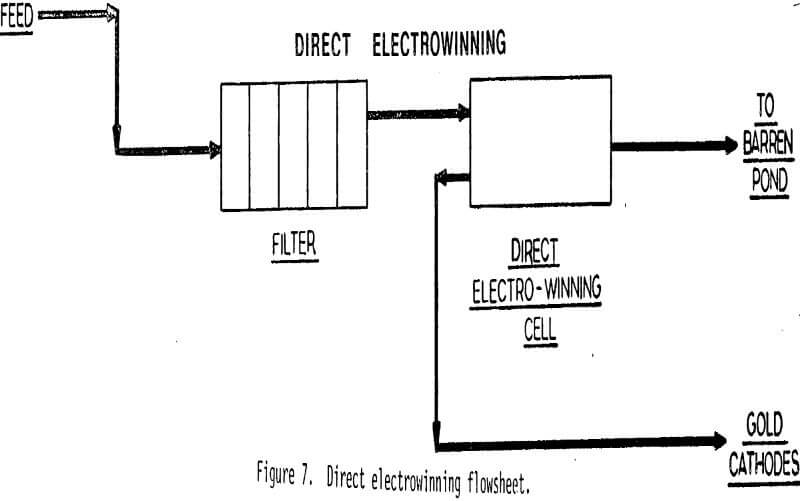

Direct Electrowinning (DEW)

Electrowinning of gold according to the Zadra technique is practiced using rich eluates generated by the stripping of carbon from carbon adsorption circuits. In the case of heap leaching and as discussed in this paper, concentrated aurocyanide solutions can be produced by the following technologies:

- carbon-in-column

- resin-in-column

- solvent extraction

Paul et al. defined a “concentrated” aurocyanide solution as having gold concentrations ranging from 50 to 2000 ppm. At these concentrations gold can be electrodeposited onto encased stainless-steel wool cathodes. The direct electrowinning (DEW) of gold from dilute aurocyanide solution represents an emerging technology which has been suggested for heap leaching operations. Dilute aurocyanide solutions from heaps are defined as those having gold concentrations in the range of 1 to 10 ppm Au.

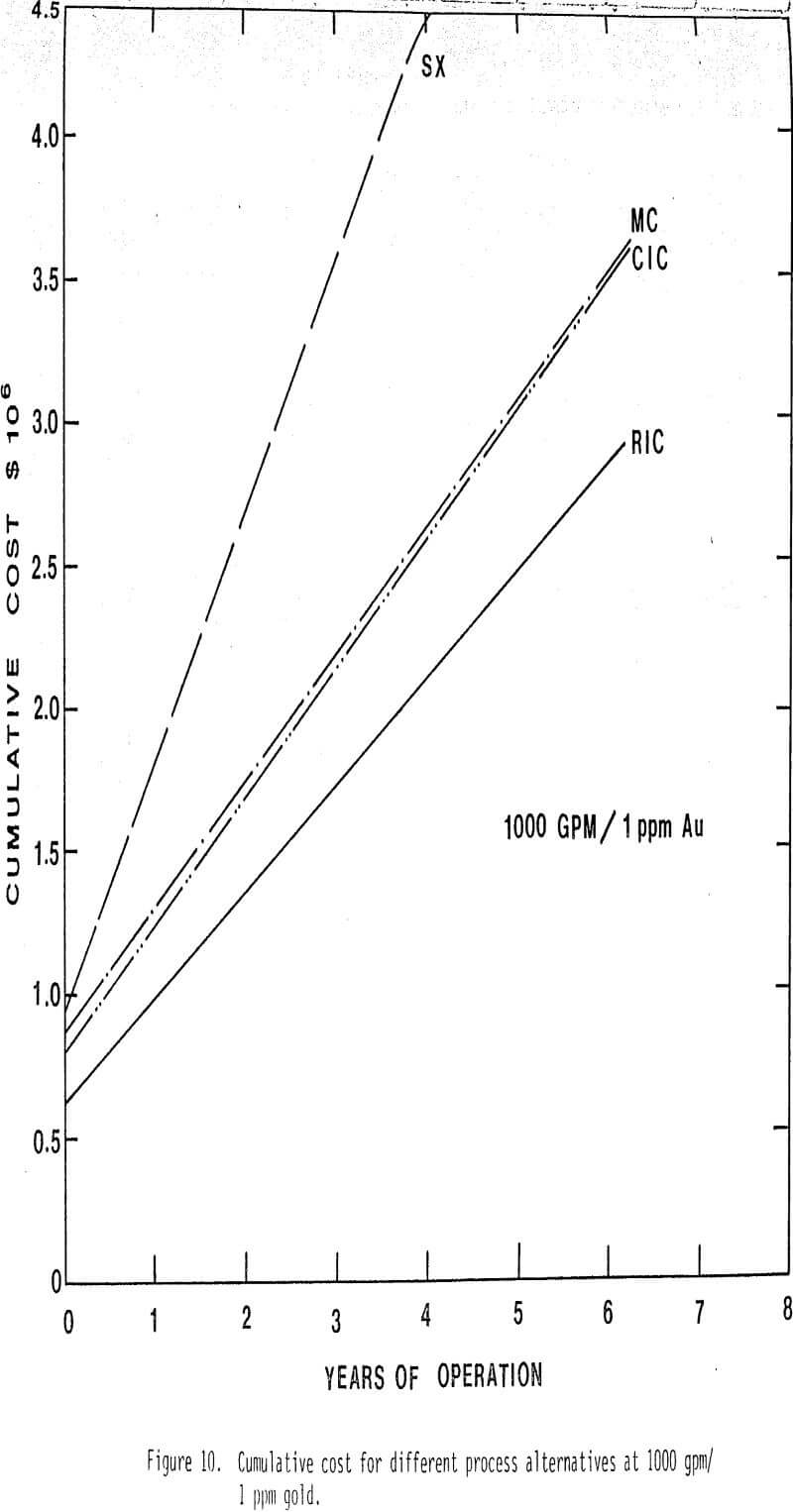

In the CIC circuit some saving could be obtained if a vertical kiln were used instead of a horizontal kiln. The vertical kiln is approximately 30% less expensive and has a far lower operating cost. However, its efficiency and effect on carbon attrition is not known and will have to be determined. Considerable savings for both the RIC and CIC could be realized if a well-developed continuous ion exchange contactor were used instead of the discrete column arrangement as conventionally used in CIC circuits. Initial calculations indicate that overall capital cost savings of about 25% for both RIC and CIC could be obtained if a continuous contactor were installed. Some of the advantages that a continuous contactor would offer are:

- lower operating cost

- reduced plant area

- high extraction efficiencies

- simpler operation

- lower carbon/resin degradation

- high security of loaded carbon/resin

- lower carbon/resin inventory and reduced gold lock-up

- no dilution of process stream (due to the use of eductors)

The potential for technology change in the recovery of gold from cyanide heap leach solution is high. This change coud be via developments in conventional technology. In the case of the carbon-in-column process, improved reactor design (continuous contactors) and improved rate/selectivity of the adsorption/desorption reactions may provide for the advance in process technology. Probably the most significant feature of carbon recovery technology is the essentially complete removal of gold from 1 ppm leach solutions.