Table of Contents

The preparation of aggregates is a form of mineral processing which has been taken for granted for many years, mostly because of its lack of glamour when compared to the winning of metallic minerals from their ores.

Many of the processes and equipment now used in the metallic mineral processing industries originated in the more prosaic preparation of aggregates. Their adaptation to metallurgical processes has led to developments both in their design and in their use. Modern practice has been so exacting in its demands that, in many cases, this improved technology is finding new applications in the very industry in which (it originated the mineral aggregate industry.

Comminution

This basic difference in principle is reflected in the object of comminution. In metallurgical practice, the only reason for comminution is the liberation of mineral particles from the gangue or matrix. In the preparation of aggregates it has a threefold purpose: a) the reduction in size of those particles larger than can be used in the concrete b) the production of a material whose size gradation will fall within limits of specifications for each sieve size; and, c) the production of shape or surface conditions required to obtain the proper strength of concrete. A secondary purpose which will be discussed later is that of differential degradation for the elimination of unsound or deleterious fractions

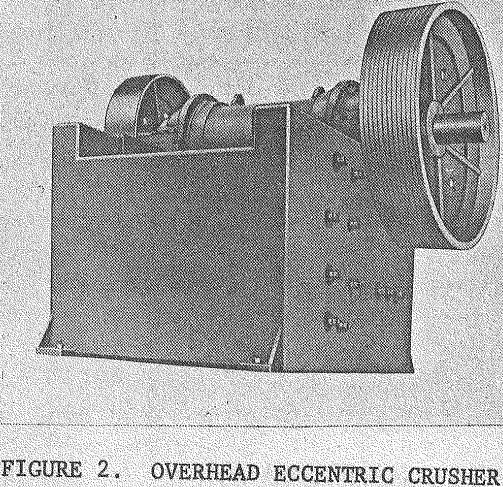

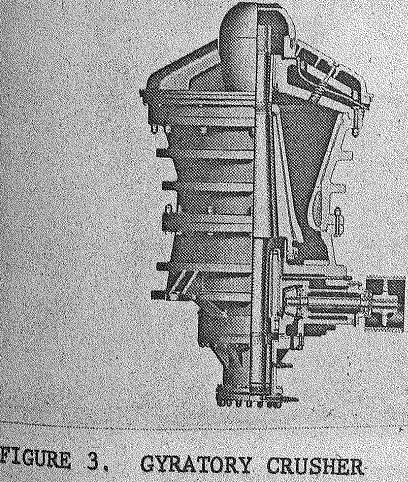

Primary Crushing

The most common, type of primary crusher is of the compression type. It is selected where the raw material is hard or tough, or where it contains abrasive fractions. Since the forces exerted by compression may break through natural fractionation planes the shape of the products may vary considerably, but since these machines are designed for a single application of external forces a minimum quantity of fines are produced. Where the material contains slabby, flat, or elongated pieces the Gyratory Crusher is more effective than the Jaw Crusher, since for the same gape there is lees straight line opening. This type is not recommended, however, where extremely hard pieces of rock will have to be broken. As a general rule the Gyratory Crusher is selected when large tonnages with no excessively large size pieces are to be crushed.

Where the rock is average in hardness, with allow content of abrasive material, does not have extreme oversize places, has a high content of clay which would prevent action through compression, attrition or shear, the Impact Crusher is usually selected. The size and shape of the products depend on the natural fractionation of the rock, but, in most cases, they are roughly cubical following natural crystallization and cleavage planes, with even distribution from the coarsest sizes, down to the finest.

Secondary Crushing

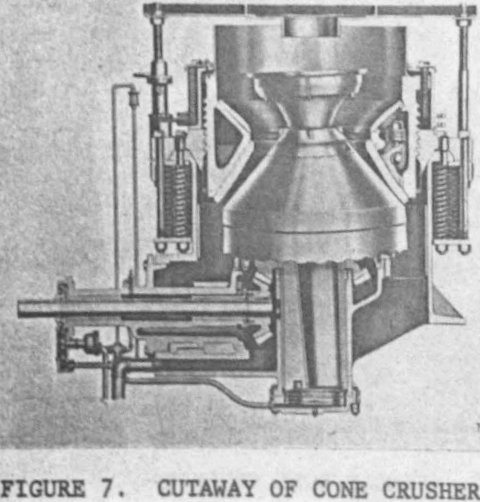

Since it is not necessary for all of the crushed products to pass a given size as it is in the metallurgical industry, it is quite common to use greater reduction ratios in the primary crushing stages of the aggregate industry, However, it is seldom that Quarry rock, and not very often that coarse gravel can be reduced to the required sizing in one single crushing operation. Just as in metallurgical practice, the aggregate industry is compelled to resort to one or more additional stages of crushing. Those fractions which have reached the finished gradations usually by-pass these stages, and quite often the oversizes from secondary or reduction crushing is recirculated until it attains the required sizing.

The same general types of crushers are used, but they have been modified since there are no more excessively large nieces to handle; the feed is pre-sized thus great reduction ratios are not necessary, but more effectiveness through prolonged action.

Fine Crushing or Coarse Grinding

As concrete technology progresses and as deposits of acceptable sands become scarcer in certain areas, this type of comminution has become quite common.

Often, because available sand is incompatible with the other components of the mix, or is deficient in certain size fractions, it is more economical to manufacture sand than to import it from a distant deposit. This is particularly true when an, average exists in a larger size fraction.

However, since the sizing of sand normally requires wet classification, the trend towards use of wet grinding mills is increasing. Where inter mediate sizes are desired the rod mill is used, where the finer sizes are sought the ball mill is used.

The aggregate industry has modified some of the practices common in metallurgy. Where nature of the rock or product desired requires only a fast grind, the central-peripheral-discharge rod mill, fed at both ends, nearly doubles the capacity of a mill of given length and diameter and is more economical in first cost and installation cost than two smaller mill. However, a careful balance of the simultaneous feed is important to effective operation. The end-peripheral-discharge rod mill is designed for more extended grinding, and the trunnion-discharge type increases the retention time still further.

Sizing

This is the final step in the preparation of aggregates. Modern specifications require accurate sizing of the various ranges of aggregates which a re proportioned into the mix to provide a concrete of designated strengths. Sizing of aggregates has therefore become very important. The concept of sizing is more precise in this territory than in metallurgy. A sized fraction is that passing one sieve and retained on the next immediate sieve in the standard U. S. Series.

According to the purpose of the screening process, three general types of devices are used:

a. The Scalping Screen – This is used to remove large pieces which would require specially designed equipment for processing.

b. The Sizing Screen which is used to return oversize fractions for further processing and to separate aggregates into closely sized fractions required by the specifications.

c. The Washing Screen, which is a sizing screen with washing sprays, also used to remove fine aggregates to the wet

classifications plant.

According to the opening of the screening medium, three general classifications are considered:

a. Coarse screening – opening larger than 4 inches.

b. Medium Screening – openings from 4 inches to ½ inch.

c. Pine Screening – openings smaller than ½ inch.

Most of the screens used are of a mechanically actuated type, with varying speeds and amplitude of motion and with varying inclination to ensure the flow of materials. Experience has determined some, general rules applying to all types of screen.

Feeding

Feeders in this industry are required to obtain maximum efficiency from the processing equipment, and to control the proportions of finished products reclaimed and fed to the blending or mixing systems. In addition proper design of feeders reduces man-power requirements to prevent hang-ups in gates, chutes, and crushers.

Apron Feeders are very common, at the coarse end of the plant. Because of the large dimensions and capacities required, these machines are heavy and costly. A modification of this type feeder is the belt-feeder used to regulate the amount of material from fine and intermediate aggregate, chutes, mostly in the reclaiming system. In the design of these feeders, as in all others, a prime consideration is that they can be used to absorb or reduce the shock load on the conveyor belts from material dropping directly from the gate onto the belt.

Plate Feeders usually of the reciprocating type are used in the feeding of material which has already passed through one or two stages of crushing. They are usually somewhat lighter in construction.

To the metallurgical engineer, an aggregate plant, at first glance appears to be a maze of conveyor-belts. This method of material handling is the most economical in power and labor and has the highest capacity for dollar invested, it also takes up more room than the average mill allows.