Crushing SAG Mill Critical Size Material

The relationship between the grinding power consumption and the product size distribution has been widely studied since it is a subject of major interest for plant design and optimization. The conventional approaches, generally of empirical nature, have led to the formation of equations such as Bond’s, which has been used in sizing most of the […]

Grinding Circuit Process Control

The inferred particle size model is a key part of the grinding control system presently being used. The model, as used during the evaluation period, related the percent +65 mesh material in the cyclone overflow to three of the mill operating variables: ball mill feed, mass flow of ore to the cyclones, and mass flow […]

Crushing & Grinding Circuit Design – Comminution

The rising costs for and the possibility for limited availability of electrical energy are emphasizing the continual conflict faced in the selection of comminution circuits used in preparing ores for concentration, namely; capital cost vs. operating cost. Frequently, the circuit with the lowest capital cost is not the most efficient in the use of electrical […]

Autogenous and SAG Semi-Autogenous Mill Design Calculations

Mill Sizing: After laboratory and pilot plant testing confirm the feasibility of autogenous or semi-autogenous grinding, it can be used to establish the exact grinding circuit and mill size. In the pilot plant tests, the tare power of the pilot plant mills should be determined before and after each test run. The tare power should be […]

Hemi-Micelle – Hydrocarbon Chain in Alkyl Collector

The marked changes in electrokinetic potentials of quartz in dodecylammonium acetate (DDA) solutions were postulated to result from the association of adsorbed collector ions into two-dimensional aggregates, called hemi-micelles. The rapid increase in flotation rate of quartz was shown to coincide with hemi-micelle formation. Micelle Hypothesis In dilute solutions alkyl ammonium and related salts behave […]

Ball Mill Scale-up Method

Ball Mill Scale-up by this method is known as collision energy based population balance model. The appropriateness of this model is shown for 38-cm ball mill. Comminution in ball mills account for a significant amount of power consumption in mineral processing plants. Therefore, accurate modeling of the process is extremely important to optimize the power […]

Copper Activation Sphalerite & Xanthate

Copper Activation Sphalerite & Xanthate: Unlike most other sulfide minerals, sphalerite responds poorly to short-chain thiol collectors. The problem is attributed to the high solubility of zinc-thiol compounds in water. Also, due to its large band gap (3.7 eV), sphalerite is a poor catalyst for mixed potential reactions between xanthate and oxygen. The reactivity of […]

Heavy Minerals Sands Processing by Rare Earth Magnets

The first known attempts to apply a REM roll separator to a heavy mineral sands application were made in South Africa and Western Australia in 1985. At that time, an ilmenite beneficiation process, which was normally achieved with cross-belt separators, was tested with a full-size machine. The performance was not good because only a single […]

Gold Pyrite, Pyrrhotite and Arsenopyrite Recovery

One of the more common classes of ores containing gold is when gold is associated with pyrite, pyrrhotite, and arsenopyrite. This is the area of gold recovery that has probably received the most research and plant optimization support especially in light of the long history of South African industrial practice. From a reagent viewpoint, charged […]

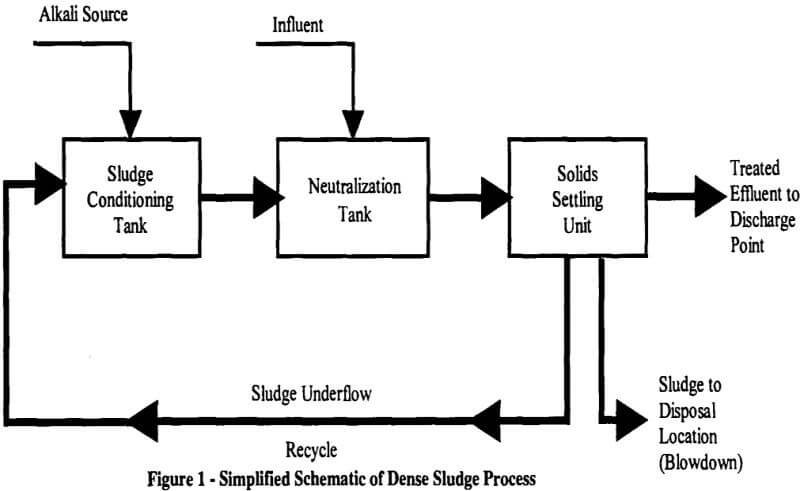

Dense Sludge Process

Figure 1 presents a simplified process flow diagram of the Dense Sludge process. The most significant change between Dense Sludge technology and conventional metals treatment is the method by which the alkali source is added. In conventional treatment systems, the alkali is added directly into the influent to achieve a desired pH setpoint. Generally, that […]