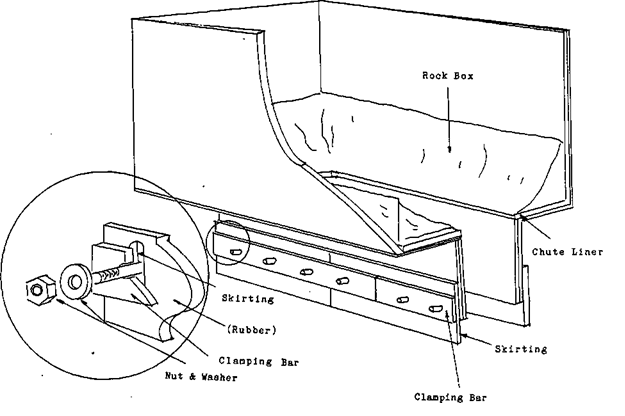

Conveyor Transfer Chute

The first one to look at is a simple two belt conveyor system, the ore will come from a draw point. This could be a fine ore bin or a coarse ore stock pile. It is transported by the first conveyor to a transfer chute where it will be transferred to the second belt. The […]

Effect of Grind Size on Gold Recovery

Your intuition along with common wisdom will have you believe the Effect of Grind Size on Gold Recovery is always uni-directional or proportional. Truth is it really depends on what your mineralogy tells you and what the effective gold grain liberation size is. If you are already finer than needed, going finer yet will not help. […]

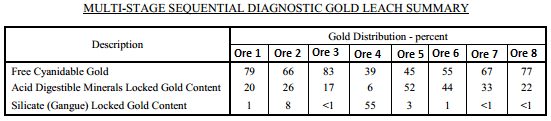

Diagnostic Gold Leach Testing

A Gold Diagnostic Leach Test is used to evaluate the distribution or deportment of gold in various minerals is determined by a series of selective leaches, usually by increasingly stronger oxidative acid leaches. Between each stage, cyanide leaching is used to extract the released gold. In this study a total of ten analysis stages were carried out for the […]

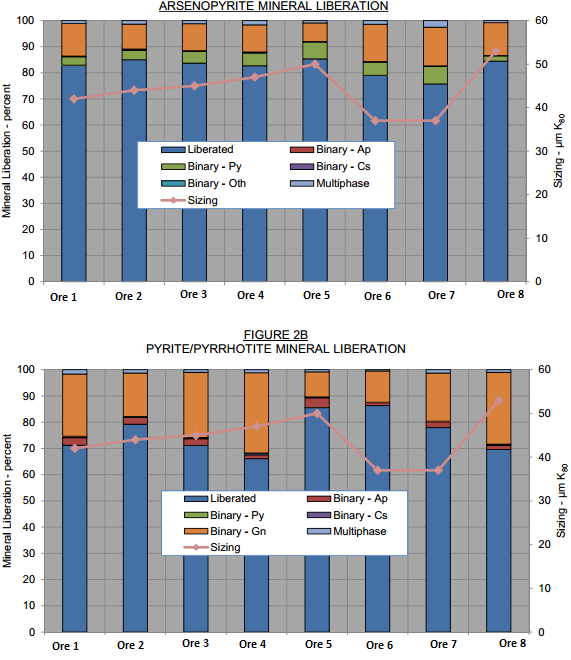

Arsenopyrite Gold Recovery

Having some arsenopyrite in your gold ore sample does not insure a full refractory gold processes is needed for recovery. The presence of arsenopyrite and heavy sulphides just tells a component of fraction of the gold extraction process might have a refractory response. This post is no handbook on procedure for treating sulphide ores for maximum arsenopyrite gold recovery, […]

Gold in Arsenopyrite

As case study for the processing of an ore with a refractory component of visible and invisible Gold associated in and with Arsenopyrite had a gold content in the feed ranged from about 1.0 g/tonne to about 8.7 g/tonne depending on lithology. There was some difficulty in measuring the feed gold content due to the presence of coarse gold in […]

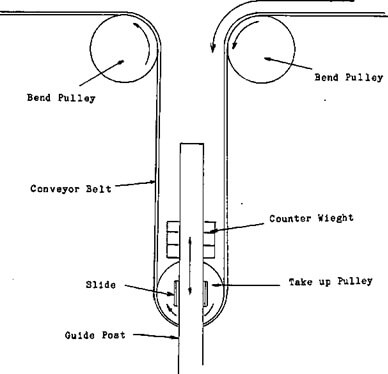

Bend Pulley

The length of this second type of conveyor requires that a BEND PULLEY and a TAKE UP PULLEY he added to the return portion of the conveyor belt. The longer belts will have a greater expansion and retraction rate due to climatic temperature changes. As temperature climbs the belt will get longer. When it drops […]

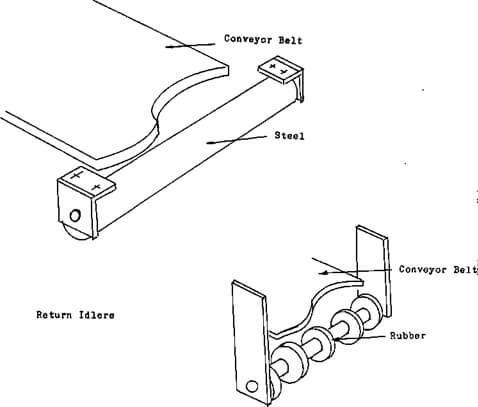

Return Idlers

If we look under the conveyor bed, we will find another set of changes. This area is called the CONVEYOR RETURN because the conveyor is returning for another load of ore. The idlers here are called RETURN IDLERS. The problems that they face are dirt and belt wander. The belt tracking will be taken care […]

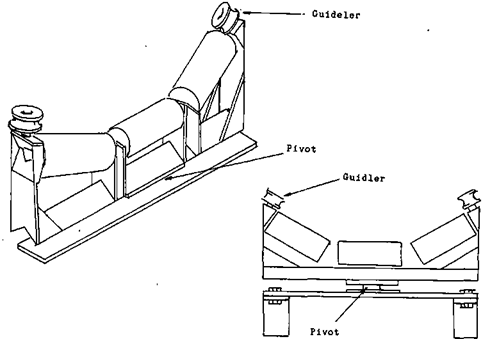

Training Idlers

Used in the troughing idler type as well as the next type we are going to discuss is the TRAINING IDLER the purpose of training idler is to keep the belt running straight. This is termed “TRACKING”. If a conveyor belt is tracking properly it is staying in the correct track. If it doesn’t it […]

Troughing Idlers

To start with the idlers, let’s look at the ones that carry the load first. They are called troughing idlers. This type of idler comes in various depths of trough. The depth used will depend upon the material being carried and the speed that the conveyor is traveling at. The deeper conveyors will carry […]

Feeder Safety

Feeders can be dangerous, so lets talk feeder safety a bit. All walkways and work areas should be kept clear for easy access and exits, don’t leave things laying on or around feeders. If you have to bar in a feeder or a chute, here are a few hints that may save you a lot […]