Refractory precious metal ores in which gold is encapsulated within iron sulfide minerals can be effectively treated by other leaching bacteria in addition to T. ferrooxidans. These include both facultative and obligate thermophiles. Use of thermophilic bacteria for microbial pretreatment of precious metal ores can offer economic advantages over common bioleaching processes in terms of both increased reaction rates and a lower requirement for cooling. Additional work is required to evaluate the relative merits of the different groups of leaching bacteria as applied to precious metal ores.

Carbonaceous gold ores can also be effectively pre-treated by facultative thermophiles to yield enhanced gold recovery. However, in most cases the bioleached residues are still active with respect to preg-robbing. Combining bioleaching with either carbon-in-leach cyanidation or blanking agent pretreatment is required to achieve satisfactory gold recoveries from these ores. Although acidification of carbonaceous gold ores decreases preg-robbing and enhances subsequent gold recovery, bioleaching is required to solubilize iron sulfide minerals and yield a product which can be cyanided in the presence of activated carbon to attain maximum recovery of precious metal. The primary drawback for application of bioleaching to carbonaceous gold ores will probably be the high acid-consumption potential of some ores.

An alternative to these methods can be found in microbial pre-treatment, a biological process whereby again iron sulfide minerals are degraded and the liberated precious metal values are available for recovery by conventional technologies. The application of bioleaching to refractory precious metal ores is a relatively new concept in comparison to roasting and chemical oxidation, and is rapidly becoming established as a viable pretreatment alternative. Numerous studies have been conducted in the laboratory and on a pilot scale. Comparative tests have demonstrated that bioleaching can be equal to or better than roasting or pressure oxidation in terms of product recovery and process economics. The primary drawback of bioleaching is that pretreatment periods are on the order of days rather than hours, and this can lead to excessive operating costs for difficult-to-treat ores.

In all of the tests reported thus far, the leaching microorganism used has been Thiobacillus ferrooxidans, a microorganism which oxidizes iron and sulfur under acid conditions. This microorganism is versatile and can be grown quite easily on pyrite, arsenopyrite, and other mineral sources. It grows at moderate temperatures and is readily inactivated at temperatures exceeding 40°C. This presents a problem in bioleaching ores with high sulfur content because the exothermic reactions release heat which creates conditions unfavorable for optimum activity of the bacterium. A microbial- based process using T. ferrooxidans would therefore necessitate the use of an associated cooling system which adds substantially to operating costs. These costs would be reduced considerably if bacteria could be used to accomplish the same goal at higher temperatures. Although the most widely-studied leaching microorganism to date has been T. ferrooxidans, there are other groups of bacteria, including some that grow at high temperatures (thermophiles), which also degrade iron sulfide minerals. Some have described two main groups of thermophiles which could be used in bioleach applications:

- the moderately-thermophilic, “thiobacillus-like” iron-oxidizing bacteria which exhibit optimum growth activity at 450-55°C, and

- the extremely thermophilic Sulfolobus species which grow in a temperature range of 50°-80°C. Both groups are acidophilic and readily leach several minerals, including iron sulfides.

Materials and Methods

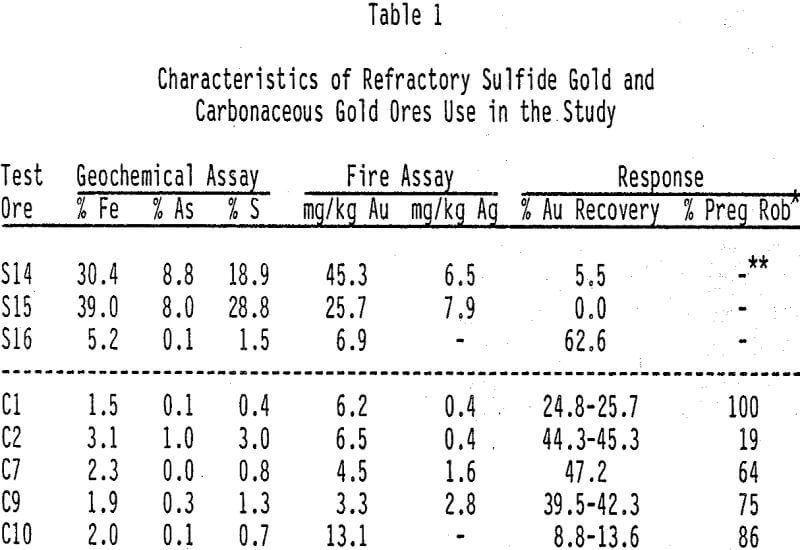

Test ore samples, consisting of ores, concentrates, and tailings, were received from various locations within and outside the continental United States. Most of the carbonaceous gold ore samples were obtained from locations in the southwestern United States. Test ores were dried as needed and ground to 90% – 200 Tyler mesh (75 µm). Samples were characterized by X-ray diffraction, X-ray fluorescence, geochemical analysis, fire assay, and other analytical tests. Table 1 presents some of the more significant characteristics of the test ores reported herein. Those ores designated with an “S” prefix are sulfide-refractory gold ores and exhibit little preg-robbing activity towards gold-cyanide complexes. Those ores designated with a “C” prefix are carbonaceous gold ores and are generally preg robbing. Preg-robbing potential (% preg rob) is operationally defined as the amount of gold removed by the ore from a 2.0 mg/l gold-cyanide solution at 25% (w/w) pulp density. Those ores with high preg-robbing potentials are termed “active.”

Leaching bacteria were obtained from several locations and maintained as stock cultures on mineral salts media with pyrite as an energy source. Mineral salts media contained 400 mg (NH4)2SO4 400 mg MgSO4·7H2O, and 40 mg K2HPO4 per liter of deionized water. T. ferrooxidans strains were maintained on mineral salts media with pyrite at either room temperature or 30°C. Facultative “thiobacillus-like” thermophiles were incubated at 50°C and Sulfolobus spp. were incubated at 60°C. Prior to initiation of a given test, starter cultures were prepared using the selected microorganism grown on the test ore; these were used to inoculate the test samples and typically comprised 5-10% of the total pulp.

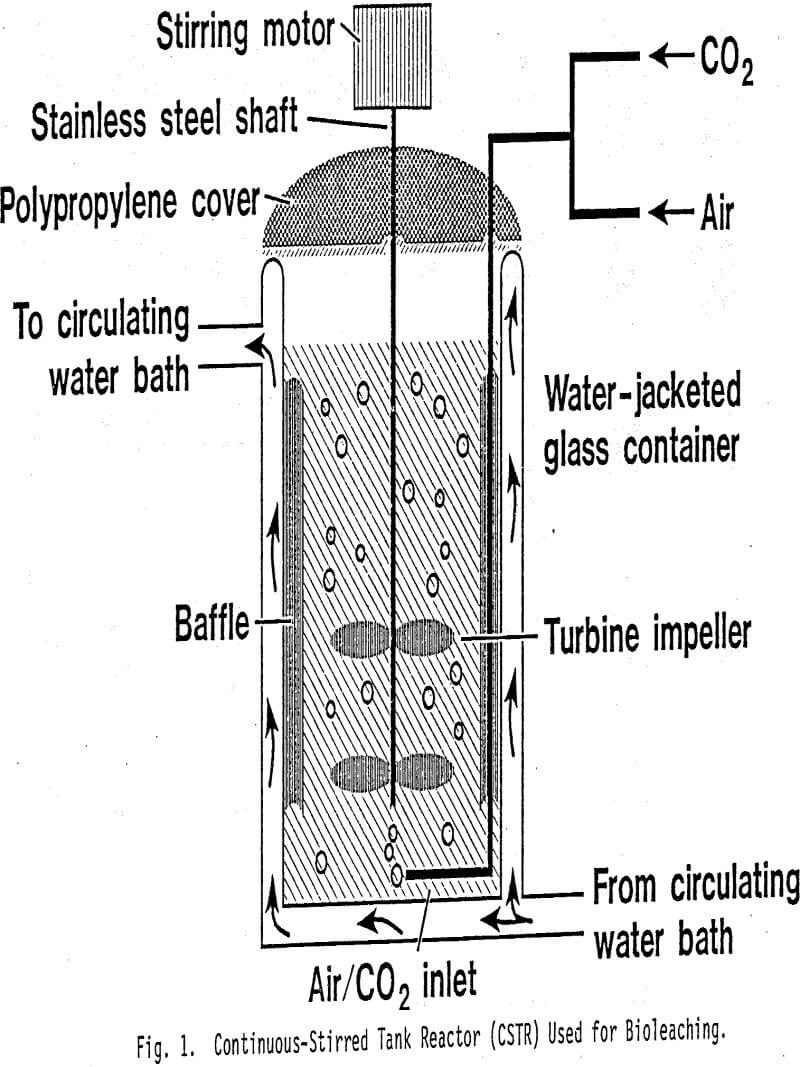

Depending on the test, one of three reactor systems was used. The smallest of these consisted of 250-ml Erlenmeyer flasks containing 0.10 kg pulp in temperature-controlled shaking incubators. The pulp volume varied, depending on the specific pulp density, but in most cases approximated one liter per kilogram. For larger scale, 3-1 Fernbach flasks containing 1.0-1.5 kg pulp were used in the incubators. Other tests were conducted with a continuous-stirred tank reactor (CSTR) system as shown in Figure 1. The CSTRs consisted of baffled, 2-1 water-jacketed glass reactors connected to circulating water baths for temperature control. Air enriched with carbon dioxide was injected beneath a stirring shaft equipped with turbine impellers and attached to a 0.5-amp stirring motor. Each CSTR contained 1.5 kg pulp.

Pulps were monitored during bioleaching for solution pH and dissolved iron. Ferrous iron levels were analyzed by titration with cerric sulfate and ferroin indicator. Total iron levels were similarly analyzed following reduction of ferric iron with lead. Iron contained in precipitation products was determined by extracting 1.0 g bioleached ore with 5-10 ml 6N HCl for 5 minutes and analyzing the extract for total iron as above. Total iron extractions were calculated from solubilized iron and precipitated iron analyses. Native ore and bioleached residues were evaluated for gold recovery by cyanidation under conditions specific for each test. Cyanided tails were washed and analyzed for gold content by fire assay. Gold extraction was calculated based on gold content in the native ore and the cyanided tails. Carbon-in-leach (CIL) tests were carried out by cyaniding either the native ore or the bioleached residue in the presence of varying amounts of Calgon GRC-11 6 x 16 mesh activated carbon. Carbon particles were screened from the cyanided pulp, and the tails were analyzed for gold content by fire assay as above.

|

|

|

|