No discussion of primary crusher selection would be complete without a comparison of the two leading types: the standard gyratory crusher and the Blake jaw crusher. Although their fields of application overlap to a considerable degree (at least in the realm of primary crushing) there is no real conflict between these two machines; one supplements the other and, between them they very effectively cover an imposingly large proportion of the entire field of primary crushing applications. This does not mean that other types, such as the sledging rolls, for example, are not better suited for certain applications; but there are very few primary crushing jobs to which the gyratory or jaw crushers, or both of them cannot be applied with at least a fair degree of satisfaction.

Either of the two types can be built to handle the hardest and toughest rock or ore that can be economically mined or quarried. The jaw crusher, because of its box-frame construction, and simple toggle mechanism, is especially well adapted to extra heavy design for the crushing of extremely tough materials: in this respect it holds some advantage over the gyratory type, because the extra strength necessary for such work can be built into it at less cost than is required for the gyratory with its more complex shell castings. However, cases where extreme brute strength enters into the selection problem are relatively rare, either type can be used for the great majority of materials encountered in crushing practice, either in standard form or in reinforced design. Strengthening of these machines for extra-heavy duty follows certain well established practices which have been proven to be necessary or desirable. Usually it is a matter of selecting stronger metals, or adding weight in the frame, or both; seldom is it necessary to change the proportions of the working mechanism.

In most cases selection of one type or the other can be made on the basis of performance characteristics, receiving openings, space requirements, and so forth, without regard to relative strength of design. In choosing between the two for any specific application it is helpful to have a list of the salient features of each type, in a form that will permit quick and easy comparison. The following lists emphasize the favourable characteristics of each machine.

Features of the Gyratory Crusher

- High capacity per dollar of investment,

- Annular discharge opening

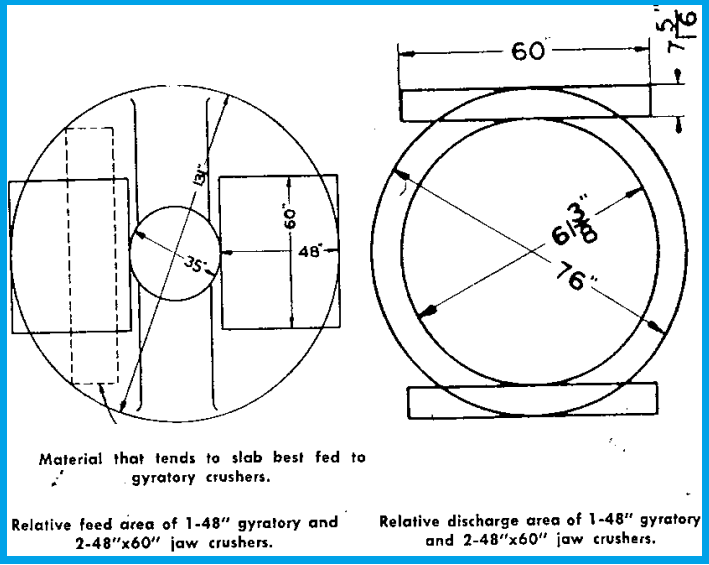

minimizes slabbing; makes for more cubical product. - Shape of receiving openings favourable for slabby material. This, plus point 2, gives the machine a distinct advantage over the jaw for handling thinly stratified stone.

- Long receiving openings, plus large area, tend to minimize bridging. See also the comments under “Transportation Equipment and Feeding Methods.”

- Double receiving openings permit dumping from two sides of crusher.

- Relatively low flywheel effect minimizes starting peaks; also allows the machine to stop quickly when power is cut off due to over-loads caused by tramp iron or choking.

- Machine can be serviced by simple overhead crawl-type hoist, whereas jaw crusher requires crane with travel in two directions to properly handle parts.

- Relatively high pinion shaft speeds permit use of higher speed motors, and lower-ratio drives.

- Lubrication is simpler and more economical than is possible to achieve in the jaw crusher.

- Cost of foundation will usually be lower than for the jaw crusher.

- Necessary safety guards are less extensive than for the jaw crusher.

Features of the Jaw Crusher

- Large receiving opening per dollar of investment.

- Shape of receiving opening favourable for blocky feed. This, plus point 1, give the jaw a definite advantage over the gyratory, except in the very large sizes, for handling rock of massive formation.

- The jaw crusher is more easily adjusted, to compensate for wear of liners. This is particularly true in the larger sizes, and the range of adjustment is greater in all sizes.

- The jaw crusher does not lose any of its “new-condition” throw when the babbitt wears in the main, or in the pitman, bearings.

- The jaw crusher will handle sticky,’or dirty feed better than the gyratory, there being no diaphragm below the crushing chamber on which such material can pack.

- Routine maintenance and repair jobs are generally more easily accomplished on the jaw crusher than on the gyratory. Major repairs are about a stand-off.

- For crushing extremely hard, tough materials extra strength can be built into the jaw crusher at less extra expense than in the gyratory. So-called “standard” designs, i.e., unreinforced, are usually more rugged than the standard design of gyratory.

Advantages and Disadvantages

Neither machine is particularly well suited to handling very soft, or “mushy” materials, although the jaw crusher is superior to the gyratory for such service. Loosely cemented minerals, such as soft sandstone, will not work well in the gyratory crusher; packing on the diaphragm behind the pipe is almost certain to cause trouble. The jaw crusher will handle rock of this character if it is reasonably free-flowing. The action on all very soft materials is inclined to be sluggish and, unless it is at the same time of a free-flowing nature, packing in the crushing chamber is an ever present hazard.

The jaw crusher will handle rock and ore containing a considerable proportion of loam, or similar contamination, provided that the admixture is not so viscous that it builds up on the jaw plates. The gyratory should never be used for materials containing more than a small percentage of such contamination, the allowable amount being that which the clean crushed rock will keep scoured off of the diaphragm. Flushing the diaphragm will prevent packing of this dirty material, but this practice is usually not permissible in the crushing plant.

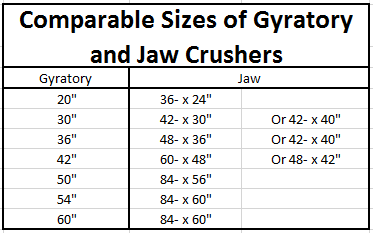

We have had occasion to use the expression, “comparable sizes,” a number of times in this work, with reference to comparisons between two types of crushers, particularly the jaw and gyratory types. This expression has been used by many writers on the subject; usually without any attempt to define exactly what it implies. As a matter of fact, it is a difficult term to define with any degree of accuracy. The Old Quarryman says, “It means two machines, one of which you would buy if you didn’t buy the other one, providing you had enough money to buy either one of them.” That comes about as near as any definition. Comparable sizes of gyratory and jaw crushers are those sizes which the engineer or operator pairs off against each other when making a selection to fit his specific problem, and these pairings may not be the same for all problems. One job may involve capacity as the most important factor; the next one may demand special emphasis on receiving opening. Obviously these different requirements may call for setting up a comparison between different sizes of one or the other type.

Usually, in selecting the primary crusher, receiving opening is the prime consideration; admitting of course that capacity must be adequate. The following list is an attempt to pair off gyratory and jaw crushers on the basis of effective receiving openings, bearing in mind that each shape of opening has its advantages for certain shape-characteristics of the feed, as has been pointed out.

Comparable Sizes of Gyratory and Jaw Crushers

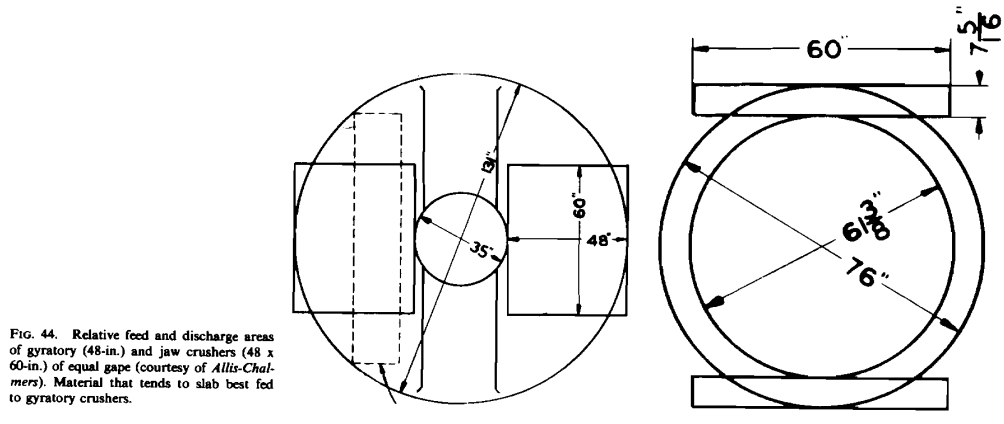

Sometimes, in making a comparison of receiving openings, it is helpful to make a scale drawing of both openings, superimposing one upon the other. The rectangular jaw opening is simple and easy to layout. To draw the gyratory opening, it is necessary to know the top diameter of the crushing head; to make a complete sketch, the diameter of the spider hub and the width of the spider arms should also be known, but this information is not absolutely essential in making the comparison. Taking half the top diameter of the head as a radius, draw the circle which represents the top of the head; then, increasing the radius by the actual opening between head and concaves at their tops, draw the circle representing the concave ring at the top of the crushing chamber. Then superimpose the diagram of the jaw crusher opening, laying it in tangent to the head circle.

To facilitate this work for the line of Superior McCully gyratory crushers, we list in the following table the top diameters of the heads, and openings between head and concaves for straight-face, and non-choking, concaves.

Laying in the plan view of the ‘ spider hub and arms will, of course, give a more complete picture of the gyratory crusher receiving openings, but the picture is likely to be a little misleading unless it is borne in mind that the maximum diameter of the spider hub is some distance above the upper rim of the crushing chamber, and therefore does not restrict the receiving opening as much as the plan view indicates. The true effective receiving opening can only be shown in its proper proportions by tilting the plan view; that is, by an angular projection normal to a plane which is tangent to the bulge of the spider hub, and to the top of the crushing head, To draw such a view requires more information, and usually more drafting skill, than the average man has at his disposal. The circle method described in the second preceding paragraph is sufficiently close for all practical purposes.

Handling and Crushing Slabby Material

If the material to be crushed is of a slabby nature, for example, a thinly stratified limestone or shale; the product of the jaw crusher is certain to contain slabs, some of which may be quite large, particularly so if some of the strata in the deposit are thinner than the discharge setting of the crusher. Nor is this tendency to slab in the crusher confined to stone of stratified formation. Some rocks of massive formation may contain parallel cleavage planes in certain sections of the deposit. Such material will slab in the crusher just the same as those rocks which were formed in definite layers, or beds.

The gyratory crusher by virtue of its annular discharge opening is an effective slab breaker. This faculty, coupled with the fact that its receiving openings are especially well suited for admitting slabby feed, give it a very definite advantage over the jaw crusher in the handling of such material.

In the foregoing comparison of these two leading types of primary breakers we have endeavoured to present the case for each of them in a fair and impartial manner. It would be difficult, and probably more than a little tedious for the reader, if we were to attempt a more definitive analysis or to set up fixed rules of procedure for selecting one or the other machine; a process which is always fraught with pitfalls in such a broad and empirical branch of engineering as the processing of rocks and ores. Usually the matter of choice can quickly be narrowed down to a comparison of one size in each type. These two machines may then be tabulated with respect to capital investment, capacity, power requirements, space requirements, and so forth; their receiving openings may be compared, as we have suggested, and all of the factors we have discussed in this section checked against the features and limitations of each machine to determine its ability, or inability, to fit into the plan.

COMPARISON OF PRIMARY JAW AND GYRATORY CRUSHERS by Weiss, N. L., Society for Mining, Metallurgy & Exploration, Pages 4