The performance of Bulk storage hoppers and silos is sensitive to the nature of their contents so consideration must first be given to the physical properties with respect to the operational requirements of the system. See the I.Mech.E publication: – ‘Guide to the specification of bulk solids for storage and handling applications’.

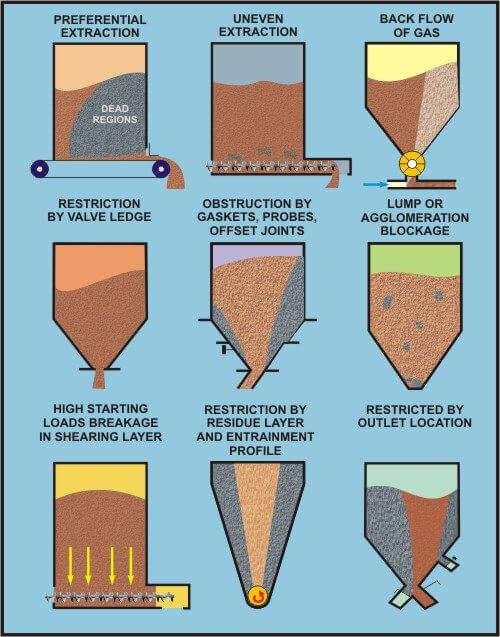

A primary feature of design is the form of flow regime that must be generated that is compatible with the product(s), which dictates the zone order of discharge of the contents. If the equipment includes a feeder or discharge device to promote or control the flow, this must be considered as an integral feature with the storage section in determining the extraction pattern.

Flow Regime:

The basic choice rests with between a ‘mass flow’ pattern, where the total contents are in motion during discharge, (although rarely at the same rate), and a form of ‘Funnel Flow’, where the flow is confined to a narrow flow channel from the outlet to the surface of the material, or a combination of local sections of both, termed ‘Expanded flow’. Funnel flow and Expanded normally draw product from the surface layers progressively drain to form a ‘Cone angle of drained repose’. The effect of this latter pattern is that freshly loaded material will empty before earlier filled product that rest in the region surrounding the flow channel. In some cases, a Funnel Flow or Expanded Flow regime will expand to the sides of the container before reaching the stored surface. This is not a matter of selective choice, but a consequential pattern termed ‘Mixed Flow’. This has the surface appearance similar to Mass Flow, but whilst having structural implications to the wall stresses, is not usually of operational significance.

|

|

|

|

|

|

|

|

|

|

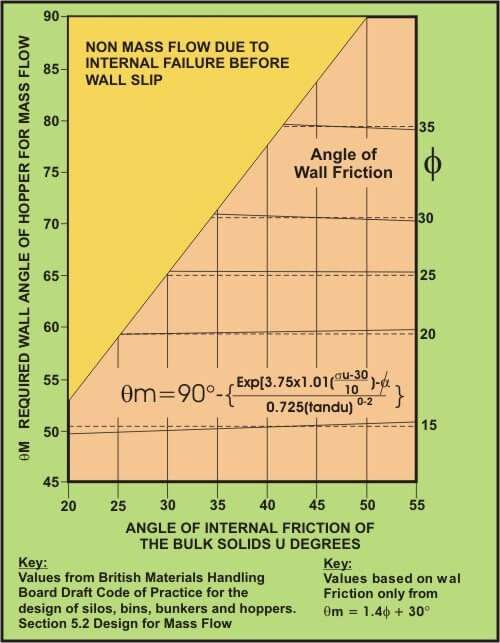

‘Mass Flow’ is essential for products that can deteriorate in flow condition or quality with time in storage units that are not completely emptied each time before re-fill. This mode of flow is also needed for products that adversely segregate, as flow of the whole cross section of the container tends to re-mix components that have deviated in direction during the filling process to settle in different regions of the hopper. This re-mixing is even more effective in hoppers fitted with a feeder that extracts progressively from the elongated length of a slot outlet. In order to ensure that the material slips on the container walls during discharge it is necessary to conduct wall friction tests with the product against a sample of the material of wall construction.

A ‘Funnel flow’ regime is generally adequate for inert bulk materials that are not cohesive and is characterised by a converging section to the outlet that is inclined only to provide self-clearing of the contents. An‘Expanded Flow’ design is generally suitable if the main issue with the product is that of discharge reliability, which depends on the flow condition of the hopper contents and the design of the outlet region of the hopper.

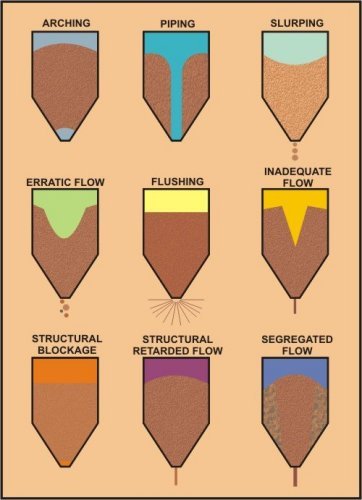

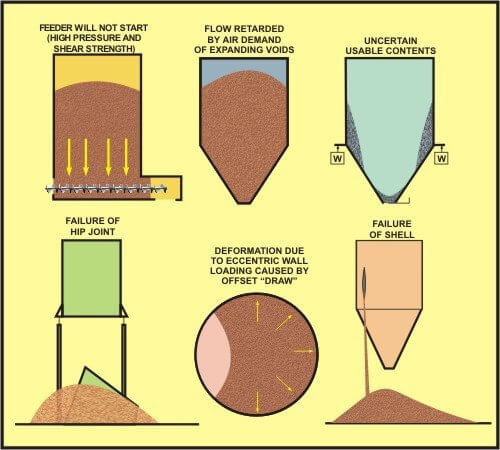

Flow stoppages

Flow will cease if the stored material develops the shear strength to form a ‘Cohesive arch’, the material blocks the outlet by lumps coming together in the flow route to form a stable ‘Structural arch’, or if the region above the outlet discharges to leave a ‘Rathole’ cavity that is surrounded by a stable mass of settled material. To avoid a cohesive arch, the outlet must exceed the ‘critical arching dimension’. This must be determined by shear testing of the bulk material and applying the well-establish Jenike process.

It should be noted that the minimum outlet size required for material acting in a funnel flow manner is approx. twice that needed for a local mass flow pattern. Lump blockage is a stochastic process with there are many particle and operational variables effecting the probability of a stable arch forming, so it is difficult to define a safe’ size of opening to avoid this hazard. See Solids Sense guide notes on blockage by lumps. Amongst the many benefits of a slot outlet Is that reliable flow is secured through much smaller widths than equivalent diameters of circular outlet and it will not block completely if an obstruction forms in one place, offering continued discharge and a prospect of erosion of the blockage by adjacent flow.

Regarding ‘Ratholes’, a hopper operating in funnel flow requires the outlet to be larger than the size at which a rathole can form. By contrast, ratholes cannot form in a mass flow regime, as slip on the wall means that the foundations for such a stoppage are constantly being removed. Nevertheless, the mass flow regime must extend at least sufficient for the cross sectional span of the flow channel to exceed the ‘critical rathole dimension’ to prevent this hazard. A hopper construction that comprises a mass flow section at the outlet region and funnel flow at a higher level is termed an ‘Expanded flow construction.

Form of container

A circular cross section Body Section is highly efficient for containing flow stresses, so relatively thin material may be employed for this form of construction. Rectangular vessels ‘nest’ far more effectively and hold slightly more in a given floor area, especially in an array. Circular bins are therefore widely used for external applications, where the cross section space taken in generally irrelevant, and rectangular bins tend to be used internally for the efficient use of floor space where this is a premium. The flat sections can also be convenient for transport, site access and local assembly. Disadvantages are that Flat surfaces are very poor for pressure containment, so that walls usually have to be stiffened with ribs.

Converging section

Flat bottom bins are normally confined for the use of inexpensive, easy-flow products, unless a form of collecting system is incorporated. Cones are widely employed to focus from a circular body to a central outlet. These commonly adopt a wall inclination of 60 degrees to the horizontal, although this angle is rarely adequate for mass flow and usually rather generous for self-clearing. Flow requires material resting in the outer regions to converge both diametrically and circumferentially, the latter being three times the former, so the resistance to deformation is much greater than in ‘V’ shaped hoppers, when the product only converges in one plane. As a result, bulk materials with slide in mass flow on flow wall inclinations that are about 10 degrees less than in cones and discharge reliably through outlets half as wide as the diameter of circular outlets. Plane flow has many operating advantages over conical flow apart from the saving of headroom, extra storage capability and better discharge characteristics, provided that the slot outlet is served by a feeder that extracts from the total outlet area. A caution is that pyramid shaped hoppers converge in two planes, so have even worst flow potential than cones because the resolved gully angle formed by the two converging surfaces have a compound lower inclination, plus a ‘corner effect’ that tends to hold residue in the sharp gullies because of the restraining effect of the large surface area relative to the force developed by the local mass.

Two behaviour problems benefit hugely from plane flow, for different reasons. ‘Segregation’ and ‘Flushing’. Segregation can have an impact on the subsequent handling characteristics of the material, or its ultimate use and value. It often tales place during the filling of a bin with free flowing materials that is composed of particles that have differing physical properties, especially those with size variations, and results in different periods of discharge being composed of differing fractions of the stored contents. ‘Flushing’ is the uncontrolled discharge of bulk material that is in a fluid condition due to dilation of the bulk. Mass flow will redress the effects of these phenomena to some extent by remixing segregated body contents during discharge and avoiding the ‘straight through’ flow of fresh loose material in funnel flow, but there is invariably a flow velocity gradient in the cross section of a converging flow route that differentiates the output. The BMHB has published a useful ‘User Guide to Segregation’. However, the effects of both Segregation and a fluidised condition of a product when loaded are also highly reduced by a progressive extraction feeder, as outlined below.

Feeders

Unless the hopper is to discharge by gravity flow, in which case a type of valve is fitted that opens and closes the outlet, some form of outlet control is required. Feed rate control by partial opening of an outlet valve is only practical with free flowing materials suitable for a funnel flow regime, as any part restriction would negate a mass flow design by the blocked area holding back a static region of product.

Feeders are integral to the overall design of a hopper system, which must be considered as a single system. Although an extra cost to the application, they provide a means to finely control the output rate, carry many process advantages and influence the flow pattern generated.

Mitigating Segregation

The notional ‘first-in, first-out’ flow pattern of mass flow will partially redress the segregation of fractions that have been deposited in differing locations of the container in the filling process, but the initial and terminal periods of discharge will tend to have different compositions to a fully homogenised mass. A feeder that progressively extracts from a slot outlet will selectively gather product from different regions along the slot and combines them on discharge. In combination with a mass flow ‘V’ shaped hopper that has a lower velocity gradient than a cone, a well-designed feeder on a mass flow hopper will effectively redress filling segregation. A flow dispersing device may also be installed below the inlet to the hopper to minimise ‘Repose slow segregation’. Proprietary devices are available, as some design care is required to avoid aggravating, rather than mitigating, the phenomenon.

‘Flushing’ in a fluid-like condition can develop with products whose composition contains a high proportion of very fine particles. These are prone to adopt a loose condition when agitated or allowed to fall freely from any distance, especially when warm because the viscosity for air trapped in the voids is more viscous at elevated temperatures, so excess air is slower to percolate from the voids between the particles and allow them to develop shear strength by contact and overlapping when settled. A fine material can flow more freely than water in these circumstances as air is the effective lubricant. Residence time and flow velocity are therefore of the essence for a fluid bulk material to settle sufficient to a stable condition, flow velocity being counter-current to the rising speed of air escaping from the bed. Discharge from a small outlet, even in mass flow, develops a much higher flow rate than extraction over the larger area of an outlet slot, so increasing the tendency to carry air down with the product. The extra capacity afforded by a ‘V’ shaped hopper also extends the residence time of the hopper contents. Processes that improve de-aeration also favour a more uniform discharge density of the hopper contents, which may be an asset on feed control, filling and packaging application for product that are filled by volume and sold by weight.

These techniques can aid the settling process considerably, but are not always sufficient to prevent density and flushing problems because fine fluid products can sometimes take a long time to settle to a stable condition. Also, every converging channel generates a velocity gradient during the flow of bulk material because the area above the outlet is the easiest gravity flow route. Should bulk material in a fluid condition penetrate a stored bed sufficient to enter a flow channel with a velocity profile, the hydrostatic pressure it generates will exceed the lateral pressure of material alongside and progressively develop a preferential path through the more settled material to eventually flush when it reaches the outlet. Various steps can be taken to accelerate de-aeration, by providing deep bed air escape routes, vibrating reeds and hopper inserts, but such generally remain the domain of experts.

Reliable Flow From Feed Hoppers