Ferrocyanide Toxicity

It is generally agreed that the ferrocyanide ion is of a low order of oral toxicity, even in relatively large dosage. Kobert states that potassium ferrocyanide in alkaline solution is nontoxic. In Precis de Toxicologie it likewise is asserted that this salt is nonpoisonous and that it is useful as a diuretic. There is recorded […]

Lethal Dose of Cyanide

The chemistry of cyanide solutions is complicated because the cyanide ion forms compounds and complexes with many elements. Some cyanide species are highly toxic whereas others are relatively inert and harmless. Molecular hydrogen cyanide (HCN) is the most toxic form of cyanide. Under most conditions, HCN exists as a gas which readily dissipates or reacts with […]

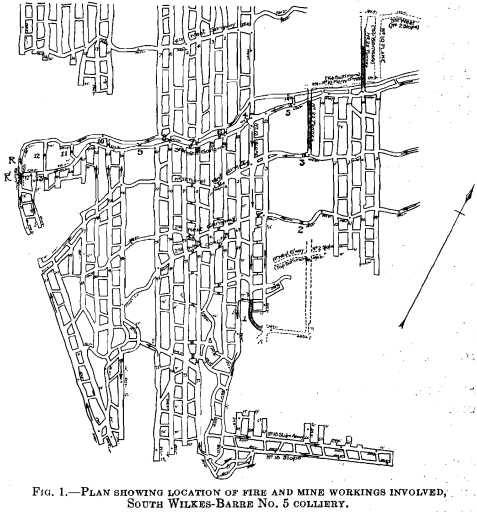

How to Extinguish a Mine Fire

In the anthracite fields of Pennsylvania, mine fires occur with more or less regularity and their existence is an ever-present hazard in coal mining. In all probability 90 per cent, of the mine fires can be ascribed directly or indirectly to the ordinary miner’s open lamp. Other causes may be smoking, electrical installations, gas explosions, […]

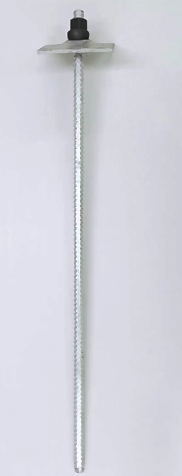

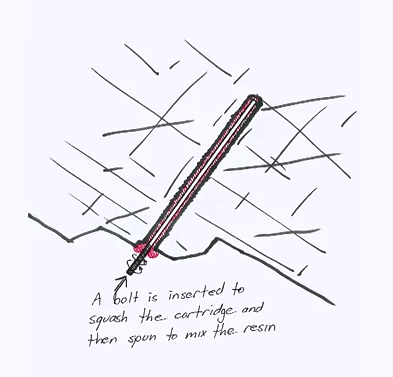

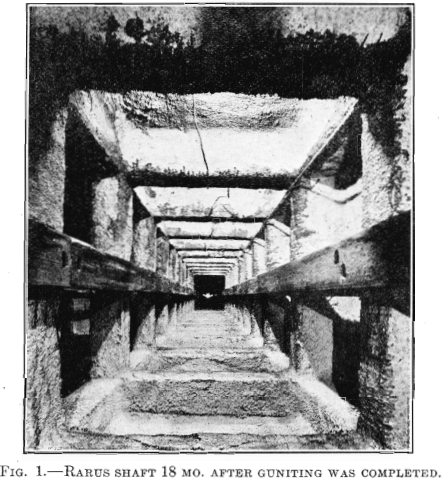

Underground Mine Water Management & Mine Roof Support

In addition to the operational issues of dust control, confined spaces electrical dangers and poor visibility that we’ve discussed in the previous topic there are two other dangers that are every present in underground environments. These are risks due to rock fall and due to water in flow. In this topic, we’ll have a look […]

Underground Mine Safety

Underground mines are inherently dangerous environments considering both illness and accidents there are around one million work related deaths around the world every year. The mining industry takes safety very seriously with an aspiration goal of zero fatalities. The safety of workers must always be of primary importance in any mining activity. Hazards in underground […]

Safety in Open Pit Mining

Welcome back to the surface mining model. In the previous topic, we learned about different types of surface mining operations, about equipment, about different methods that are commonly used to extract coal or different ore deposits. It’s not difficult to understand that mining is one of the most dangerous working environments in the world and […]

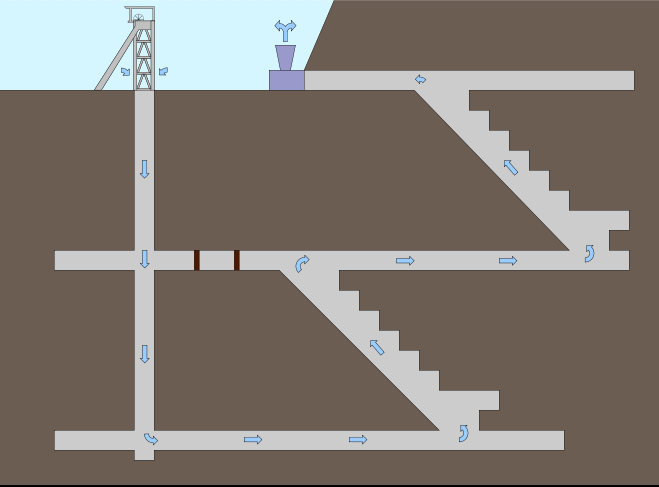

Underground Mine Ventilation

Something that all of the various and mining techniques have in common board and pillar, stoping, caving, long wall mining; is that they take place in underground environments where fresh air does not naturally occur. Not surprisingly, ventilation is a critical importance to the occupational health and safety of underground workers. A continuous supply of […]

Cyanide Poisoning Antidote

In 1910, the Committee of the Chemical, Metallurgical and Mining Society of South Africa, appointed to investigate cyanide poisoning, recommend as an antidote to Cyanide Poisoning the following: Thirty cc of a 23 per cent, solution of ferrous sulphate. Thirty cc of a 5 per cent, solution of caustic potash. Two grams of powdered oxide of […]

Underground Mine Fire Prevention

During the winter and spring of 1917, an unprecedented number of underground fires occurred in the Butte district. With one exception, these fires were caused by the failure of electrical equipment, and called attention to the increased fire hazard in underground mining operations occasioned by the extensive use of electricity. Five local conditions that contributed […]

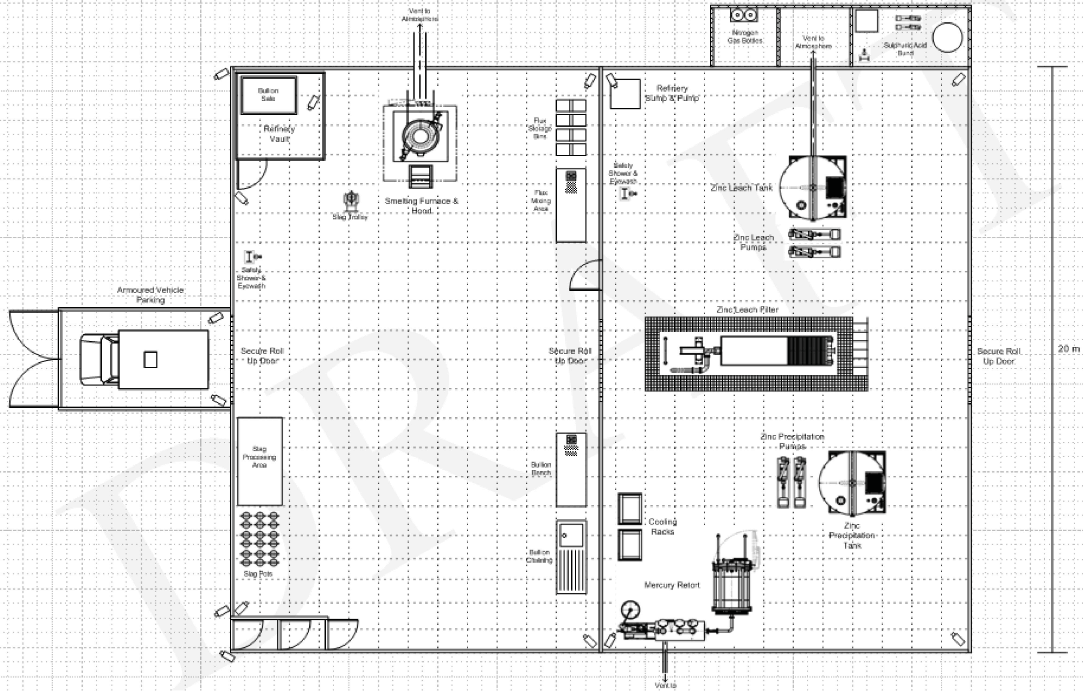

Gold Room Security

Very little is documented about Gold Room Security due to the sensitivity of people around it. At the same time, when establishing a new operation it is useful to have a standard security starting point on which to address the issues with directly related to gold room security design fundamentals. This paper will provide guidelines and a ‘prompt’ […]