The world demand for gold and international economic pressures for an advance in price have accelerated interest in gold and silver production. Many opportunities exist throughout the world for small cyanide plants both for production and pilot operations, especially in areas not easily accessible, and where labor and local costs are on a level for profitable operation. Ores not fully amenable to treatment by amalgamation or flotation processes for the recovery of gold and silver can often be profitably treated by the cyanide process to produce bullion as a final product.

The problem of designing a small cyanide plant is a difficult one in view of the various factors involved. It is usually necessary to incorporate, on a smaller scale, the same elements as in larger plants while trying to keep the cost factors within economic limits. Features to insure high recovery, continuous trouble-free service and ease of operation must be carefully considered. Through laboratory test work to develop the best procedure, followed by experienced design and planning of all details are items essential for reduced costs of installed plant and operation.

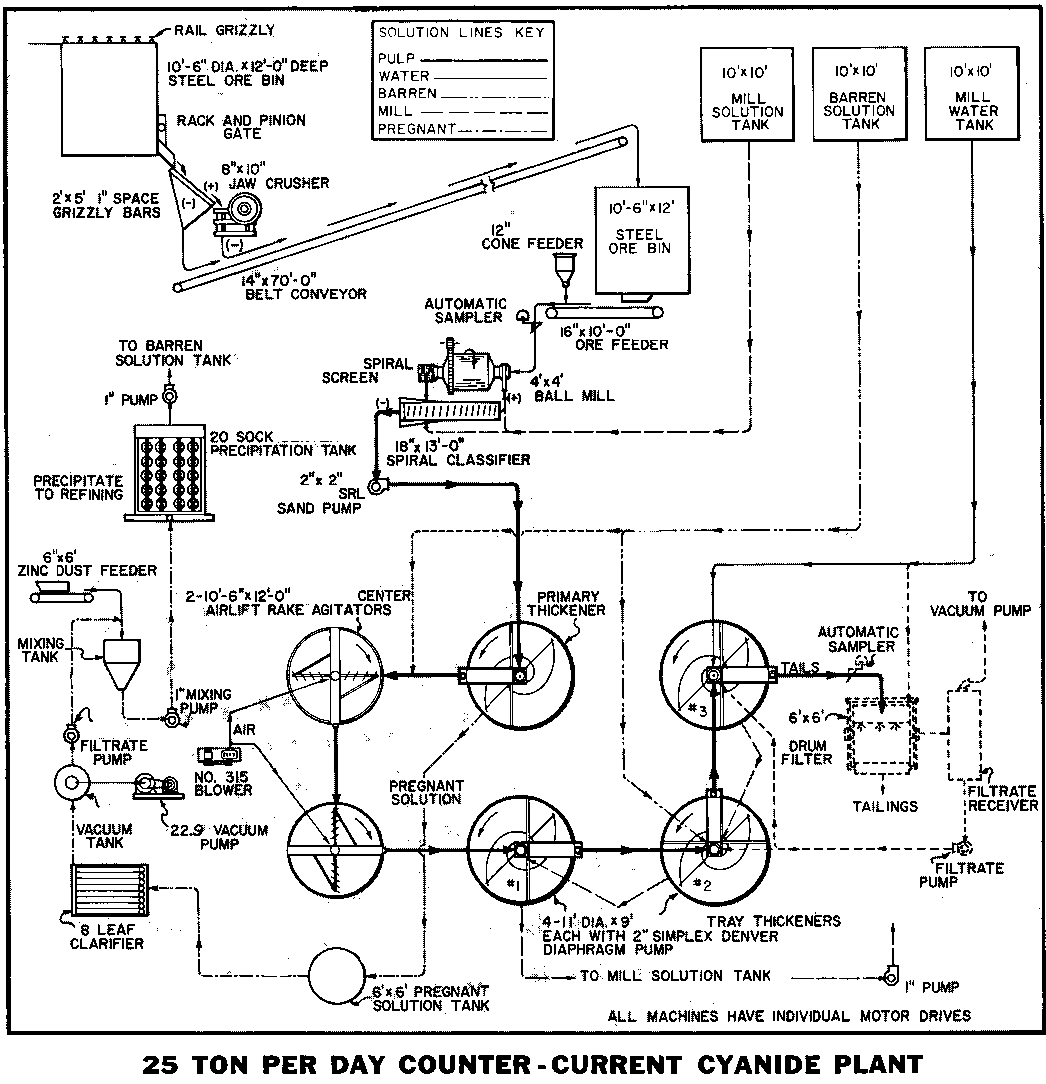

Flowsheet

The flowsheet illustrated is one which has been proven in a number of operations and can be adapted to meet conditions best suited for the character of ore to be treated. This flowsheet and process is only briefly described herein due to space limitations since the subject of cyanide practice is described in other publications by EQUIPMENT COMPANY.

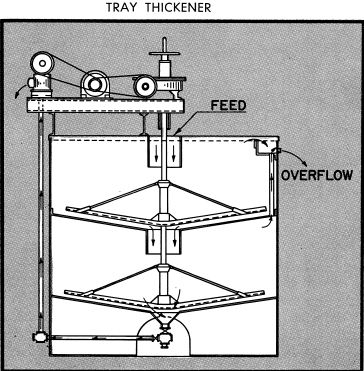

This flowsheet assumes the mill site to be nearly level except for location of steel ore bin. It provides for crushing in open circuit to minus one inch and grinding and classification of an average ore to minus 100 mesh with overflow from classifier to primary thickener at 25% solids. Lime is added to the ball mill for alkalinity control together with mill cyanide solution for dilution. About 75% of the recoverable values are usually disolved in the grinding circuit. The overflow or pregnant solution from the primary thickener goes to the bag-type zinc dust precipitation unit for recovery of the values as a precipitate. The underflow from the primary thickener is pumped at 50 to 60% solids to two Center Air Lift Rake-Type Agitators in series. Barren solution as necessary is added to the first agitator to maintain the pulp at near 50% solids. A retention period of 48 hours is provided in the agitators. Air from a positive type rotary blower at 12 PSI is connected to center air lifts to provide agitation and aeration. From the agitators the pulp flows to three counter-current single tray washing thickeners. Two- inch Diaphragm Pumps transfer the settled solids from one thickener to the following one at a pulp density of 50% or higher solids. It is important to maintain the percent solids as high as possible since this greatly affects the degree of washing in each unit. Wash water is added to the last washing thickener in a quantity to balance water lost in the tailings and through evaporation. Barren solution recovered from the precipitation unit is used for washing in the second wash thickener. In the flowsheet a Drum Filter with washing sprays is indicated as an alternate to be used when very high grade ores are treated to reduce losses of dissolved values and cyanide in the tailings. A fourth washing thickener may be desirable with or without the washing filter depending on the nature of the ore.

Barren solution as necessary is added to the first agitator to maintain the pulp at near 50% solids. A retention period of 48 hours is provided in the agitators. Air from a positive type rotary blower at 12 PSI is connected to center air lifts to provide agitation and aeration. From the agitators the pulp flows to three counter-current single tray washing thickeners. Two- inch Diaphragm Pumps transfer the settled solids from one thickener to the following one at a pulp density of 50% or higher solids. It is important to maintain the percent solids as high as possible since this greatly affects the degree of washing in each unit. Wash water is added to the last washing thickener in a quantity to balance water lost in the tailings and through evaporation. Barren solution recovered from the precipitation unit is used for washing in the second wash thickener. In the flowsheet a Drum Filter with washing sprays is indicated as an alternate to be used when very high grade ores are treated to reduce losses of dissolved values and cyanide in the tailings. A fourth washing thickener may be desirable with or without the washing filter depending on the nature of the ore.

The Zinc Dust Precipitation Unit provides for clarification of pregnant solution from the primary thickener by leaf filters suspended in the solution tank ahead of zinc dust precipitation.

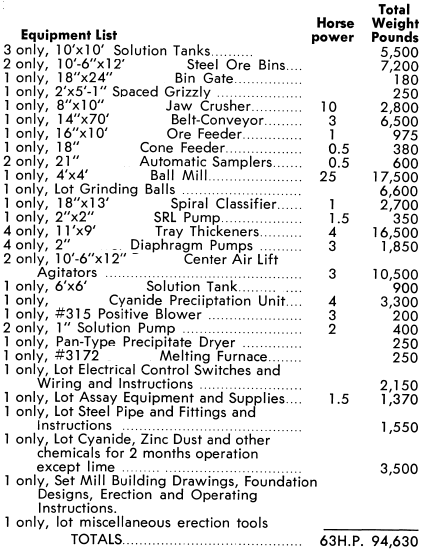

Cyanide Plants can be furnished for any desired capacity. This 25-ton-per-day counter-current plant is available as a complete package plant including all items of equipment, tanks, piping, electrical components, tools, assay and smelting equipment. The single open tray thickeners of the type illustrated provides greater capacity per square foot of area than standard units and result in a saving both in first cost and in handling and installation. These can be mounted on a concrete pad for ease of installation. All tanks shown are designed to allow nesting to reduce shipping volumes which is important for units prepared for export shipment. Also most component parts and other items can be packed in the tanks for shipment. Items required for a 25-ton plant are: