Without mineralogy, estimating the optimum Grind Size for Gold Ore Sample is most conveniently made by Laboratory Testing and the agitation leaching method, and it will be necessary to make up 3 or 4 bottle charges in order to have enough ore* for the subsequent screen analysis.

Without mineralogy, estimating the optimum Grind Size for Gold Ore Sample is most conveniently made by Laboratory Testing and the agitation leaching method, and it will be necessary to make up 3 or 4 bottle charges in order to have enough ore* for the subsequent screen analysis.

Take an average sample of the ore and grind on the bucking table to pass No. 30 sieve. Weigh up 4 lots of 300 grams each and place in 4 standard acid bottles, add to each the quantity of lime estimated from the alkali consumption test, and water in the ratio of 3:1. For addition of cyanide it is best to make up a concentrated cyanide solution and ascertain the strength by titration. The number of cc equivalent to a given weight of cyanide may then be run in to the charge of ore and water in the bottle from a burrette. The volume of liquor to be so added may be allowed for when diluting the pulp, so as to give the exact ratio of solution to ore originally decided on. It is usually advisable to shake up the bottle containing the ore water and lime before adding the cyanide.

Add sufficient cyanide to make a solution strength of 0.3 % KCN, stopper the bottles securely, and place in the agitating wheel. For the purpose of this test it is well to give an agitation period of 6 or 7 days. Treatment of sand by agitation will usually give the same result as by leaching, only in less than half the time. For the first 3 days of agitation (and longer if the cyanide consumption continues to any considerable extent), open the bottle each day and test 10 cc of the solution for cyanide and alkali. If necessary add lime and cyanide sufficient to maintain alkalinity between 0.05 and 0.1, and cyanide at 0.3% KCN.

Some metallurgists prefer to add a given amount of cyanide and let the experiment run the full time of treatment without testing and maintaining the cyanide strength. This does not seem to have anything to recommend it, and is at variance with normal working conditions, because it is usual in practice to maintain the cyanide strength at a definite figure for all or the greater part of the time of treatment. Moreover, it may often happen in making a bottle test on an unknown ore that the whole of the cyanide added at the start may be consumed long before the time of treatment is up, and the fact is not known till the end, resulting in a useless experiment and wasted time.

The object of this test is to obtain the maximum dissolution of precious metals from each grade of material, leaving out of sight for the moment commercially economical conditions.

At the end of the period the solution is titrated and consumption of cyanide calculated, but the result thus shown should not be used for basing working figures upon. The charge is then washed, either on a laboratory filter or by decantation. In the latter case the four charges may be combined in an enamelled bucket, and settled, decanted, and washed, as one sample. The whole is afterward dried, and 1000 grams weighed up for screen analysis, while a sample of the remainder is assayed as a check.

A convenient screen series for the sizing will be Nos. 40, 60, 80, 100, 150, and 200, or if the Tyler Standard screens be used, 35, 48, 65, 80, 100, 150, and 200. If desired the —200 product may be further separated into granular and colloidal matter by panning, though such a division made by this means is arbitrary, and results obtained by different operators are not comparable.

For the screen analysis it is often more satisfactory first to separate out the colloidal matter by panning and then dry the granular part before screen sizing. Another plan is to remove the colloids and the finest of the sand by washing them into a bucket through a No. 200 sieve under the water tap. The two products are then dried separately, and the oversize graded in the usual way. In this case there will probably be some —200 sand left in the original oversize which may be screened out dry and added to that which was washed through the sieve with water.

Some metallurgists prefer to do the whole of the screen-sizing in water, and this has the advantage of avoiding any possible error due to decrepitation of the larger particles in drying, but such a risk is small when the drying is conducted at a low temperature; moreover, water screening takes longer to attain the ultimate limit of separation between each grade, and there is a danger of stopping the operation before it is complete.

In dry screening the common practice of putting a washer on the screen or rubbing the pulp on it with a block of wood is not to be recommended, because it forces through the meshes particles which would not otherwise pass, giving a higher reading for the minus product than the correct one, and incidentally it displaces the wires making the mesh irregular and soon impairing the standard quality of the screens besides materially shortening their life. The main incentive to this practice is the difficulty often experienced through blinding of the meshes by the clayey matter in the ore. For this reason it is recommended that the colloids be first removed by water washing, but if it is found necessary or advisable to dry-screen a sample entire, the meshes may be kept free from the fine slime by continually tapping sharply on the top edge of the sieve with the handle of a spatula or other similar instrument, and in this way good time may be made even on very colloidal material.

In the case of ground pulp that has been wet and subsequently dried, however, this method is not satisfactory as the colloidal part in drying forms hard pellets or granules which remain on the screens, and are recorded as sand. In such cases in order to obtain reliable results the dry pulp should be thoroughly disintegrated in water and the colloids floated off before the screen test is made. If a known quantity of the dry pulp be first weighed up the sample after disintegration in water may be washed on the 200-mesh screen under the water tap, the part that passes being allowed to run to waste, and the amount calculated by difference. In this case, as already stated, the portion remaining on 200 should after drying be re-screened on a 200 sieve as it will be found possible to make a further elimination of -200-mesh material in this way.

A list of screens and their apertures comparing the Tyler Standard, and the Institution of Mining and Metallurgy (London) standard will be found among the tables at the end of this book.

The assays of the various sizings will give a good indication of the degree to which comminution should be carried in order to liberate the precious metals, and expose them to the action of the cyanide. It is well to check the result by multiplying each assay by its proportional percentage, and dividing the sum of all the products by 100. The result should check closely the assay of the sample taken out before screen sizing.

The test may afterward be repeated using 0.1% cyanide strength, and only 2 or 3 days agitation, in order to get an idea as to the maximum size of particle that will give a good extraction under the usual conditions of slime treatment.

It is often instructive to make a screen analysis of the pulp before cyaniding, so as to see how the assay values are distributed, and what percentage is extracted from each grade.

“All-sliming” Tests

Having obtained an idea of the effect of cyanide treatment on each grade of material, an “all-sliming” test may be made, with the object of finding out the probable maximum extraction by simple cyanidation.

The ore is ground so that the whole will pass a No. 200 sieve, and 250 grams weighed up for a charge. Lime is added in accordance with the experience gained in the previous test, and the dilution made up to 3:1 with water to which the necessary amount of cyanide has been added to give a strength of, say, 0.3% KCN. The bottle is placed in the agitating wheel and treated for 3 or 4 days, the solution being titrated each day for cyanide and alkali, and the strength maintained at the original figure.

Grinding Samples to a Given Screen Size

It is impossible in the laboratory to imitate exactly the degree of grinding in a working scale mill by using a certain screen size as a standard. For instance, if it is decided that a — 100-mesh product is desired an operator may produce several entirely different degrees of grinding though using the same mesh screen, according to the frequency of the screening. If screening is done after long intervals of grinding, on a bucking table or with closely set discs if using a disc grinder, the resulting product though nominally —100 mesh will have a far finer character as a whole than if the screening be frequent during bucking or if the discs of the grinder be set apart and gradually closed up after each screening. And probably none of the products obtained by these different procedures will correspond to the pulp of a mill where — 100-mesh grinding is aimed at. In one case known to the writer the product obtained from a bucking table, putting everything through a 100-mesh sieve, only contained 50% of — 200 material whereas the finished mill pulp on the same ore contained 5% of + 100- mesh material and 75% of —200. It is thus apparent that deductions drawn from laboratory extraction results on pulps all of which pass a given screen size must be received with discrimination.

In all experimental work a rule should be made never to dry prior to cyanidation a pulp that has once had water added to it. If, after amalgamating or concentrating a sample, it is desired to grind it finer, this should be done wet, with a pestle and mortar or some similar contrivance, and the screening should be done in water or solution.

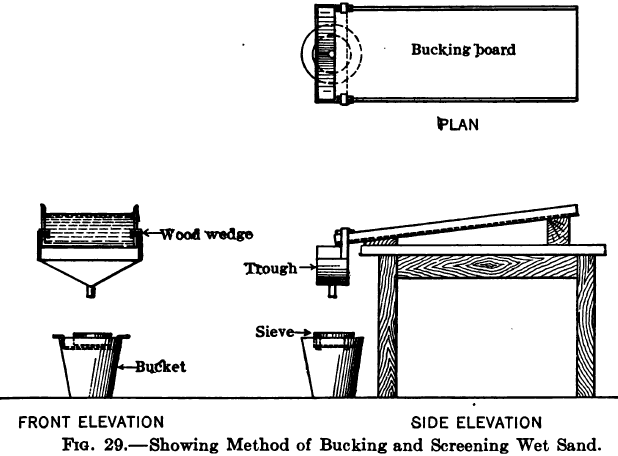

The regrinding may be done satisfactorily in a small tube mill if certain precautions are observed. The usual tendency in this method is to overgrind the sample; that is, if it is desired to grind to —100 mesh and the sample is kept in the tube mill until all will pass the said screen the resulting product will be for practical purposes a — 200 pulp. If a 200-mesh grinding is aimed at the resulting pulp will be far finer than would be produced on the milling scale with the same end in view, and the result is that the extraction results may be quite misleading. To avoid this the product to be re-ground should be first wet screened on the desired sieve and the oversize only placed in the mill. This oversize is then allowed to grind for 5 to 15 minutes and is then removed and screened, the oversize being replaced in the mill. This process is repeated until all will pass the screen. A good scheme for regrinding wet sand is to take an ordinary bucking table and raise the back end a few inches with some wooden blocks and attach to the front a narrow wooden trough of hopper shape with a ½-inch nipple at the apex.

This may be clamped on or wedged onto the edge of the bucking table so as to be easily and quickly removed. The sample is then bucked down in the usual way using just enough water to form a paste that will not run off by gravity. Just as in dry bucking the pulp is periodically screened by washing it down with a wash bottle and a piece of rubber belting onto a screen of the desired size suspended over a bucket of water.

For purposes of weighing a given quantity for a test the specific gravity of the pulp may be determined or a portion of it dried to ascertain the percentage of moisture, and then sufficient of the wet pulp taken to give the required weight of dry ore, due allowance for contained moisture being made when adding water or solution to produce the dilution needed for treatment.

The reason for avoiding the drying of a sample is that this procedure, even when artificial heat is not applied, tends to oxidize its less stable constituents and produce changes which may materially affect the results of subsequent cyanidation.

Before starting a series of experiments considerable care should be expended in getting a really representative sample of the ore, mixing, grinding coarsely (say to No. 20 sieve), and cutting down to an amount sufficient to serve for the whole series. This should be again well mixed, and stowed away in a covered can or box.