Grinding is generally considered to be a size reduction operation. However, in most cases the primary objective of grinding is the liberation of valuable minerals from gangue material, irrespective of the amount of size reduction required. If fracturing of an ore occurs in a random manner, it may be possible to use the grain size distribution of the valuable mineral phase in the unbroken ore as an indication of the overall product size which must be achieved. On the other hand, if preferential fracturing of a mineral phase results in a concentration of that phase in the finer size classes, then the grain size distribution is not necessarily a good guide to use to attain a certain product size. In this case, grinding to a size corresponding to the grain size distribution may lead to unnecessary overgrinding.

Thus, a proper mill design should consider not only the product size distribution, but also the manner in which the mineral phases liberate. For example, it may be possible to use a relatively coarse grind if the valuable mineral phase is found to liberate preferentially. Unfortunately, very little information exists regarding the breakage behavior of composite particles and the conditions under which preferential liberation may or may not occur. In fact, it has only been in recent years that computer-controlled image analysis equipment has been available to study such behavior.

The purpose of this paper is to present the results of a research program which was undertaken to characterize the effects of grinding mill operating parameters on the breakage rates of free and composite particles. Specifically, the operating parameters of mill speed, ball size and mill filling have been investigated with particular emphasis on how these parameters affect the breakage of composite particles.

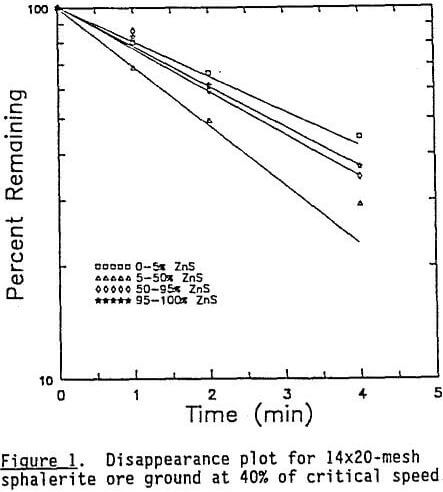

Breakage rates for each condition tested were obtained by plotting on a semi-log scale the percent remaining in a given narrow size fraction versus the grinding time. A typical example of this type of plot is shown in Figure 1 for the tests conducted at 40% of critical speed. In general, the disappearance plots for all conditions tested were either found to be first order with some data scatter, or exhibited a decreasing breakage rate with time. Therefore, in order to compare the various operating conditions on the same basis, it was decided to use initial breakage rates in all cases.

The purpose of this investigation was to study the effect of mill operating parameters, specifically, mill speed, ball size and interstitial filling, on the breakage and liberation of the components in a sphalerite/dolomite ore. As a result of this work, the following conclusions can be drawn:

- The breakage of particles with a high sphalerite content appears to be enhanced under conditions which promote impact breakage.

- The breakage of particles with a high dolomite content appears to improve in an attrition environment.

- Over the range of operating parameters studied, the specific breakage rates of free dolomite particles were not significantly affected by changes in operating conditions and appear to be energy-normalizable in almost all cases.

- The breakage rates of particles with a high sphalerite content were greatly influenced by mill operating conditions and could not be normalized with energy.

The use of image analysis procedures to obtain information of this type is relatively new, and little information is available in the literature. A practical implication of the findings reported here may be that a mill designed to provide a high-impact breakage environment might actually promote the liberation of sphalerite at a relatively coarse overall grind, resulting in a net savings in energy.