If the ore feed to any gyratory or jaw crusher consisted entirely of large cubes or spheres of a size that would just barely enter the crushing chamber, the crusher could not be expected to produce anything like its normal rated capacity because the upper part of the crusher could not shatter the large pieces enough to keep the rest of the crushing chamber busy. Such a condition is of course never met with in actual practice. We occasionally encounter special applications where the crusher is called upon to handle pieces which are all of the same size, but in such a case the machine is chosen with a large enough receiving opening to permit the pieces to fall at least a short distance into the crushing chamber before they are nipped. Even so, the crusher is not apt to perform up to its rated capacity on such a feed, unless the receiving opening is quite large with respect to the feed size.

By far the greater number of crusher applications involve feeds which are either graded (a mixture of large, medium, and small particles), or sized to a top dimension well within the effective receiving-opening dimension of the crusher. Primary crusher feeds usually fall under the “graded” category, and reduction crusher feeds under the “sized.” Graded feeds may or may not have the under-size removed, depending upon the nature of the operation and of the material. Sized feed for reduction crushers is generally a screened feed which has definite maximum and minimum limits.

The effect of the undersize in the feed upon the capacity of the crusher depends upon several factors. If the crusher is a primary breaker, and the discharge opening is large, undersize will usually sift readily through the voids between the large pieces of material, and discharge quickly. The material must, of course, be free-flowing to behave in this manner. For such a condition, large quantities of undersize may materially add to the rated capacity of the crusher, but it must be admitted that such a condition is the exception rather than the rule. More often than not the discharge setting, even in primary crushers, is such that the crushed material in the lower part of the crushing chamber effectually throttles the flow of fine material to the pace of the larger pieces; hence, any increase in capacity would be due entirely to whatever increase in density of the body of material might result from the presence of the fines in the voids between the larger pieces. This is usually not large, and as has been pointed out, the presence of fine material may even be detrimental under certain conditions.

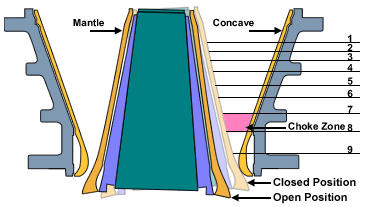

If a clean, sized feed to a reduction crusher includes a prevalence of particles smaller than the dimension between crushing surfaces at the choke point, the effect upon capacity will be beneficial. On the other hand, if there are enough larger particles to trap these smaller pieces, we get the same throttling effect mentioned in the preceding paragraph, unless the choke-point is well up in the crushing chamber, where the small pieces have a better opportunity to sift through. If capacity alone were to be considered in selecting the feed size for a reduction crusher, the ideal would be a feed having a one-way dimension not exceeding the choke-point dimension, and not smaller than the close-side discharge setting.

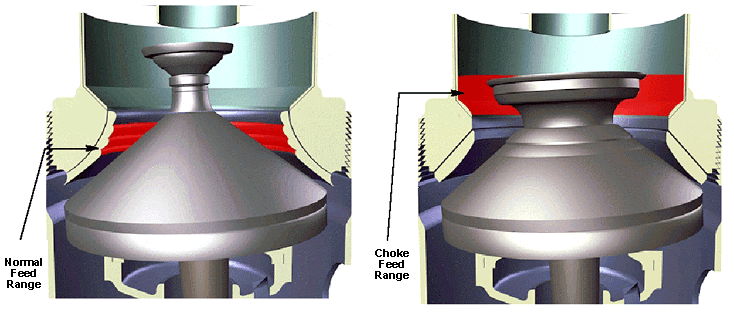

Choke-Feed VS Regulated Feed

The product from crushers of the standard gyratory type, or the older reduction types, as well as all types of jaw crushers, will be affected to some extent by the method of feeding; that is, whether the machine is choke-fed or not. The choke-fed crusher produces more fines, due to attritional grinding between particles in the crowded crushing chamber. The difference will not be as marked if the machine is fitted with non-choking concaves, but it will still be measurable. Likewise, the choke-fed crusher will usually show somewhat higher power consumption, because it takes power to produce these fines. When these types of crushers are used for secondary or reduction work, and operated under choke-feed conditions, the feed should preferably be introduced from one side, allowing it to flow around one of the spider arms to fill the bowl on the opposite side to a point just above the choke-point. This method of feed will show a marked improvement over the full- choke method, both from the standpoint of clean product and lower power consumption.

A crusher with a high choke-point incorporated in its design is not appreciably affected by choke feed. When these crushers are fully buried, the choke-point throttles back the material so as to prevent overloading the lower part of the crushing chamber, and there is so little active crushing surface above the choke-point that very few fines are produced in this zone. The facts outlined in the preceding paragraph apply to the action of the crusher on screened feed. We have stressed the desirability of screened feed for all reduction and fine-reduction crushers. If it should be necessary to feed unscreened material to such machines, they should never be choke-fed. The feed should be regulated by mechanical means to a point safely within the rated capacity of the crusher, so -that the chamber will never be more than partially filled with material. It goes without saying that even this expedient will not work on damp, sticky material.

The facts outlined in the preceding paragraph apply to the action of the crusher on screened feed. We have stressed the desirability of screened feed for all reduction and fine-reduction crushers. If it should be necessary to feed unscreened material to such machines, they should never be choke-fed. The feed should be regulated by mechanical means to a point safely within the rated capacity of the crusher, so -that the chamber will never be more than partially filled with material. It goes without saying that even this expedient will not work on damp, sticky material.