In the study, batch cleaner tests were conducted to confirm the target regrind size and select the cleaner pH conditions. The objective of the high pH, collector-starved environment in the cleaners is:

- To liberate and reject attached silicates,

- Depress the previously-floated pyrite.

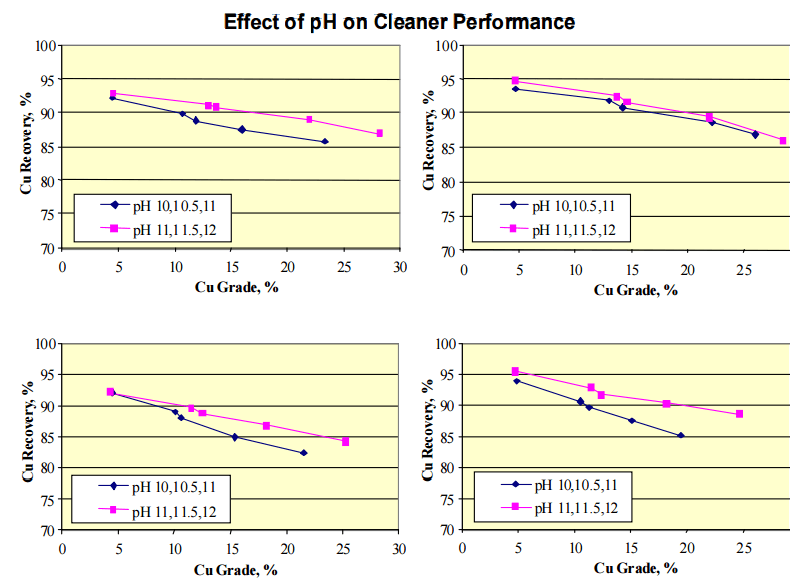

If the floatability imparted on the pyrite in rougher flotation is not adequately depressed during regrinding and cleaning, it will continue to float. The role of lime as a pyrite depressant in also higher when higher pH levels are used. Accordingly, higher pH levels were adopted for cleaner flotation to enhance selective flotation of copper VS pyrite.

Concentrate regrinding to a product size of 80% passing 30 µm is adequate to yield, after three stages of cleaning at pH 11-12, a final concentrate assaying 31% copper. Cleaner times in the laboratory were short, at 3 minutes (first cleaner), 1 minute (cleaner scavenger), and 2 minutes (2nd and 3rd cleaners). Overall copper recoveries were 90%, on average. Gold recoveries were 49%.

Mineralogy data clearly supports a need for concentrate regrinding, the primary grind of 80% passing 150 µm being considerably coarser than the primary copper sulphide grain size (averaging about 40 µm). Batch regrind and cleaner testing on the four samples indicated the finest regrind of 80% passing 20 µm yielded better grade recovery curves and the highest final concentrate grades on two and three of the samples respectively. However mineralogical modal evidence from mineral processing laboratories showed potential for the samples to yield excellent concentrate grades assaying 30% to 32% copper following regrinding to 30 µm. It was believed that the very short regrind time required for the coarser regrind using the testing rod mill may have left some of the pyrite surfaces inadequately “cleaned” and therefore depressed the recovery. Subsequent testing confirmed this.

Based on an average primary copper sulphide grain size of about 40 µm, and liberation analysis, it is reasonable to believe that a regrind product size of 30 µm should be suitable for the majority of the ore because it is dominantly the primary sulphide type. During the mapping testwork phase an additional four locked cycle tests were conducted to investigate the effect of coarser grind on final concentrate grade and recovery. Comparing the results of the four tests done at a target regrind P80 of 45 µm with the initial tests done at a target regrind P80 of 30 µm.

In all four cases the final concentrate grade decreases.On average the coarser regrind had a P80 of 44.8 µm and a copper grade of 23.3%, while the finer regrind had a P80 of 27.0 µm and copper grade of 29.4%. The coarser regrind showed a slightly higher average recovery, 92.7% versus 91.6%, which was possibly due to a slight increase in rougher circuit mass pull during that round of tests. Gold showed similar upgrade behaviour to copper at the finer regrind, but recoveries marginally lower in three of the four tests. The secondary copper mineral grain size is moderately finer, averaging 17 µm, and requires a finer regrind. This ore type is processed early in the mine plan and therefore a target of 25 µm was selected for the basis of the regrind design.