In your process development you may sometime want to test and see what effect (for your particular ore sample) would the use of oxygenation and pre-aeration have on silver and gold kinetics leach rates and recoveries. Some situations show improved precious metal recoveries, others show an impact of the leach agent’s consumption rate. Here, a flotation cleaner test was conducted to produce sufficient pan and cleaner concentrates to evaluate the effect of pre-aeration using oxygen on gold and silver cyanidation extraction.

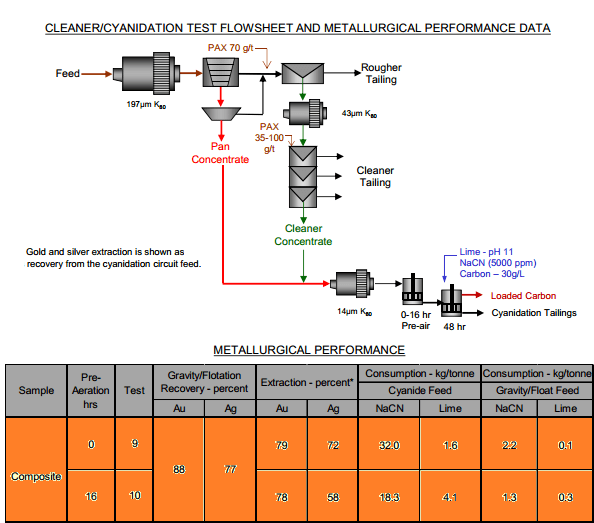

The composite was ground to a nominal P80 of 197µm and subjected to a gravity concentration followed by hand panning. The gravity tailings were subjected to a rougher test followed by regrinding the rougher concentrate to P80 = 43µm prior to three stages of dilution cleaning. The pan and cleaner concentrates were combined before being reground to a nominal 15µm.

A sub-sample of the reground concentrate was subjected to 16 hours pre-aeration prior to cyanidation, whilst the remaining sample was subjected to cyanidation without pre-aeration. A schematic of the test flowsheet, along with a summary of test results, are displayed here. The presented data is

further discussed as follows:

- Gold cyanidation extraction was about 79 percent. Pre-aeration did not appear to have any considerable effect on gold cyanidation

extraction. - Silver cyanidation extraction varied between 58 and 72 percent, with pre-aeration hindering extraction. This may be due to a

passivating layer forming on the surface. Lead nitrate addition may overcome this. - Sodium cyanide consumption levels decreased from about 32 to 18 kg/tonne when the sample was subjected to pre-aeration. This is

the equivalent of about 2.2 and 1.3 kg/tonne, respectively, of overall feed. Lime consumption increased with pre-aeration.

Pre-aeration for 16 hours, using oxygen, of reground combined pan and cleaner concentrates did not affect gold cyanidation extraction, which was about 79 percent. However, sodium cyanide (NaCN) consumption in the cyanide circuit dropped significantly from 32 to 18 kg/tonne, the equivalent of 2.2 and 1.3 kg/tonne of mill feed. Silver extraction decreased from 72 to 58 percent with pre-aeration indicating possible passivation occurring. Addition of lead nitrate may be required to assist silver dissolution.