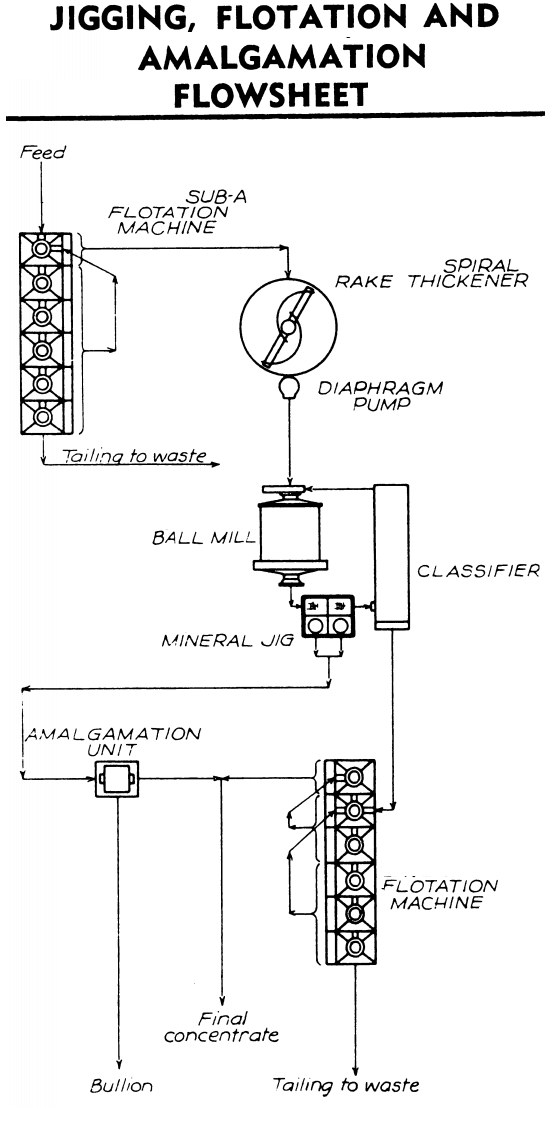

CIRCUIT PROCESS FLOWSHEET DESCRIPTION: A Mineral Jig of the flotation concentrate regrinding circuit followed by selective flotation with amalgamation of Jig concentrates.

ORE TREATED: Sulphide gold ores, principally those containing some values in copper or lead in addition to precious metals. This flowsheet is applied to ores containing large amounts of pyrite which contains intimately associated copper or lead sulphides as well as gold, and requires fine grinding to liberate the copper or lead minerals and gold from the pyrite. Fine grinding of gangue and sulphides is too costly and is not required for a low tailing.

ADVANTAGES: This flowsheet greatly improves gold bullion recovery and allows the production of a high-grade copper or lead concentrate and rejection of a barren pyrite. A bulk rougher concentrate is made with a coarse grind and a low rougher tailing is discarded. The coarse bulk flotation concentrate is reground with a Mineral Jig in the regrind circuit and the fine free gold is recovered by the Jig for amalgamation and production of bullion. The classifier overflow passes to a selective flotation circuit where depressants are used to prevent the barren pyrite from floating, and a high-grade copper or lead concentrate is produced and the barren pyrite rejected as tailing.

PROCESSING COMMENTS: In treating ores of this type a fraction of the gold is freed in the primary grinding circuit and may be removed by a Mineral Jig and amalgamated with production of bullion.