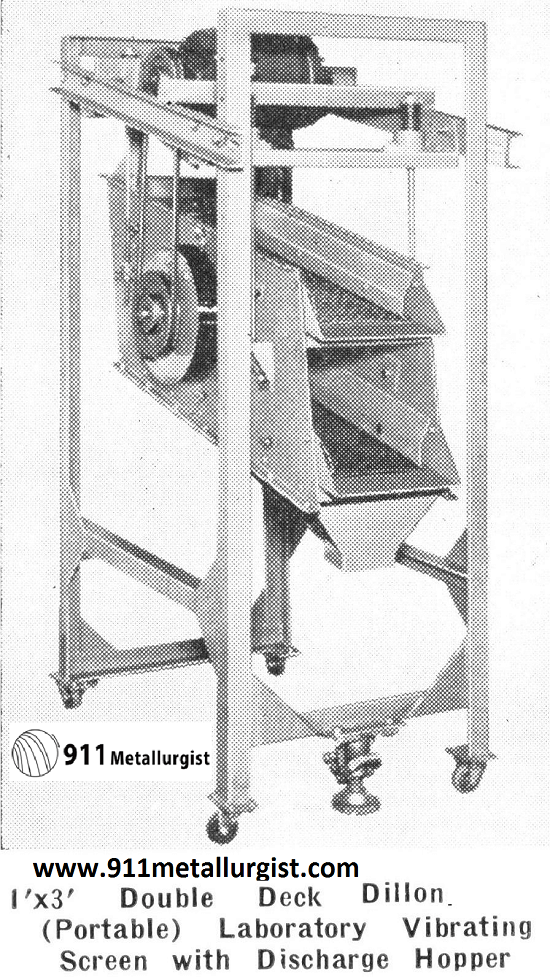

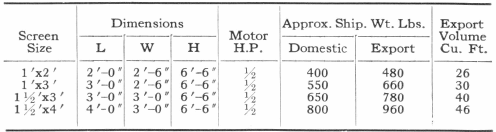

Portable Laboratory Vibrating Screen

Dillon (Portable) Laboratory Vibrating Screen is available as a self-contained unit for experimental and production work. This small portable machine has the same “Floating Circle” action as the larger, higher capacity Dillon Vibrating Screens and gives the same quiet, efficient, care-free performance.

The patented design of this unit requires just two bearings instead of the four used in ordinary mechanical screens. This cuts power costs in half and reduces maintenance costs by eliminating the additional two bearings and shaft.

The driven sheave and balance wheels are on the center line of the shaft. The shaft supports no other load and is subjected to no flexing or bending; it rotates freely on its central axis. Demountable assemby may be completey removed from either side.

Tension is uniformly maintained on quickly replaceable screen sections and rubber-cushioned camber bars arch the screen sections and prevent whipping and undue vibration. For separations at 65 mesh and finer, these bars must be spaced closer together than standard.

Standard machines are arranged for single or two-deck operation, mounted on casters, provided with floor lock, and equipped with feed hopper. A back plate, front plate with extended spouts, fines hopper and cover plates provide a complete dust enclosure with feed and discharge openings beaded for attachment of flexible chute connections or “socks.”

The suspension frame pivots on the rear support and angle is adjustable on 2½ degree graduations in the front supporting member. The ½ H.P. motor is carried on a spring mounted base plate on the suspension frame. Three-deck machines can be furnished.

Let us make recommendations for equipment and layout to suit your particular continuous test plant screening installation.

Additional data gladly furnished upon request.

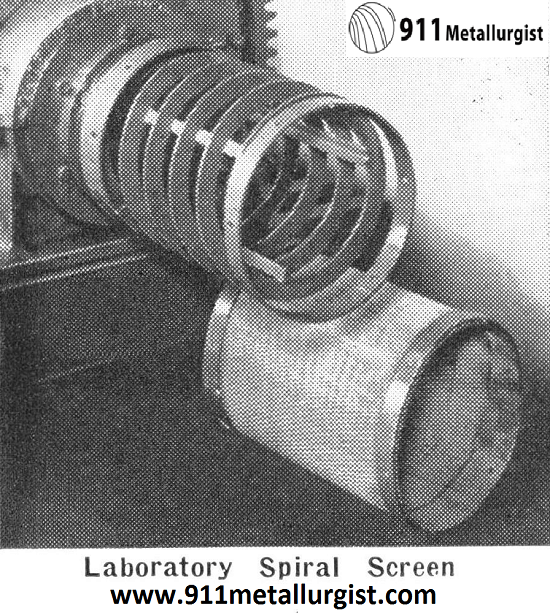

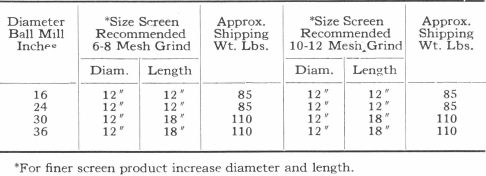

Laboratory Screen, Spiral

The Laboratory Spiral Screen is designed to make a sized product from the ball mill discharge, particularly for ‘‘Sub-A” Laboratory Unit Flotation Cells and concentrating tables. It is also used to screen out and return to the ball mill, any oversize in a ball mill-classifier circuit. This is important metallurgically, as well as accomplishing the return of trash such as wood chips and pieces of steel to the ball mill, thus keeping circuit where they might damage other units or at least cause a lowering of operating efficiency.

The unit consists of a heavy, wear resistant, steel spiral made in one continuous piece. At the feed and discharge ends, the spiral is supported by a steel flanged collar with heavy ribs to hold the flights as a single rugged member. The proper mesh screen cloth is placed around the spiral frame and held in position by bands which press against the outer surfaces of the flanges and spiral flights. The Laboratory Spiral Screen eliminates short circuiting through the screen because the pulp is compelled to follow along the entire length of the steel spiral. A center screw can be furnished to automatically return the oversize to the grinding section.

Laboratory Sieve, Tyler Standard

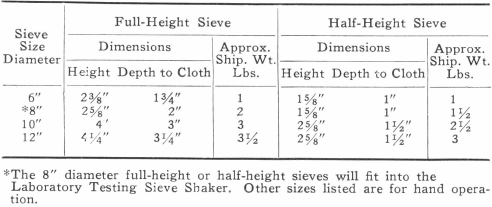

The Tyler Standard Laboratory Sieve has as its base an opening of .0029 inch which is the opening in the standard 200 mesh testing sieve. The opening increases in the ratio of the square root of 2 or 1.414 on each succeeding size, namely 150, 100, 65 mesh, etc. These sieves are made with seamless brass frames and with brass or bronze cloth. The sieves may be nested together for convenience in making a screen analysis and should always be provided with bottom pan and top cover to facilitate the sifting operation and protect the fine wire cloth when not in use.

A standard set of Tyler Sieves recommended for general laboratory and mill use includes the following 8″ diameter full-height sieves: 3, 4, 6, 8, 10, 14, 20, 28, 35, 48, 65, 100, 150, and 200 mesh plus bottom pan and top cover. These sizes are carried in stock, available for immediate shipment. Coarser sizes up to 1.05 opening and finer sizes down to 400 mesh are also available for special work if required. The 8″ diameter sieve will fit the Laboratory Testing Sieve Shaker and this unit will handle up to 8 full-height nested sieves or 16 half-height nested sieves, including bottom pan and cover. For specifications, dimensions, and operating details on this machine see Laboratory Testing Sieve Shaker.

Tyler Standard Laboratory Sieves are all within the specifications of the United States Bureau of Standards and are also marked with the equivalent United States series number.

Source: This article is a reproduction of an excerpt of “In the Public Domain” documents held in 911Metallurgy Corp’s private library.