Magnetic separation is a process used to separate materials from those that are less or nonmagnetic. All materials have a response when placed in a magnetic field, although with most, the effect is too slight to be detected. The few materials that are strongly affected (magnetised) by magnetic fields are known as “Ferromagnetics”, those lesser (though noticeably) affected are known as “Paramagnetics”.

Magnetic separation is a process used to separate materials from those that are less or nonmagnetic. All materials have a response when placed in a magnetic field, although with most, the effect is too slight to be detected. The few materials that are strongly affected (magnetised) by magnetic fields are known as “Ferromagnetics”, those lesser (though noticeably) affected are known as “Paramagnetics”.

Ferromagnetics require relatively weak magnetic fields to be attracted and devices to separate these materials usually have magnets that are permanently magnetised (“Permanent” magnets do not require electricity to maintain their magnetic fields). Paramagnetics require stronger magnetic fields and these can only be achieved and maintained by “electro” magnets (large wire coils around an iron frame – current is continuously passed through the coils creating the magnetic field within the iron. The field is concentrated across an air gap in the circuit).

Both ferromagnetic (low intensity) and paramagnetic (high intensity) separation devices (Laboratory Magnetic Separator) may be operated with dry solids or with solids in pulp form. (A complete classification of magnetic separating devices is given in Wills “Mineral Processing Technology”, pp. 338-356).

Magnetic separation has two major applications in mineral processing plants:

- The removal of tramp iron (which would deleteriously affect subsequent processes) from an ore stream. This is usually achieved by a low intensity magnet suspended above, or at the head of, a conveyor.

- Separation of magnetic minerals from less magnetic minerals.

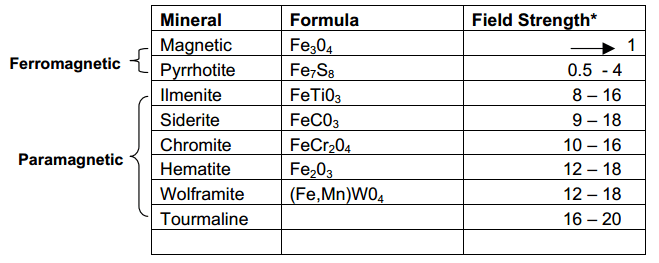

This table shows the more common magnetic minerals and the range of field intensities that may be required to separate them.

Some Common Magnetic Minerals

(*The units given are kilogauss (kG). These are the units most commonly used. The equivalent S.I. unit is the Tesla (T) * 1 Tesla = 10 kilogauss). The extremes of field strength used are based on experience from a magnetic separation testing laboratory over many years.

Eddy Current Separator

|

|

| Laboratory Wet Drum Magnetic Separator WLIMS | Industrial Mag Separator |