The first objective of Mineral Processing and Extractive Metallurgy is to remove the Mineral as soon as freed and as coarse as possible” is the first rule in treating complex ores. Ores containing two or three metals have been satisfactorily treated for a number of years. Today, however, ores containing as high as four, five and even six and seven minerals are being efficiently concentrated. Such ores have always presented difficult problems. Only in the last ten years, after detailed studies and experiments were conducted both on methods and equipment, have treatment plants for highly complex ores reached any marked degree of success.

Two LEADING Mineral Processing and Extractive Metallurgy METHODS

The two dominating principles which have brought greater efficiency to recovery of values from highly complex ores have been:

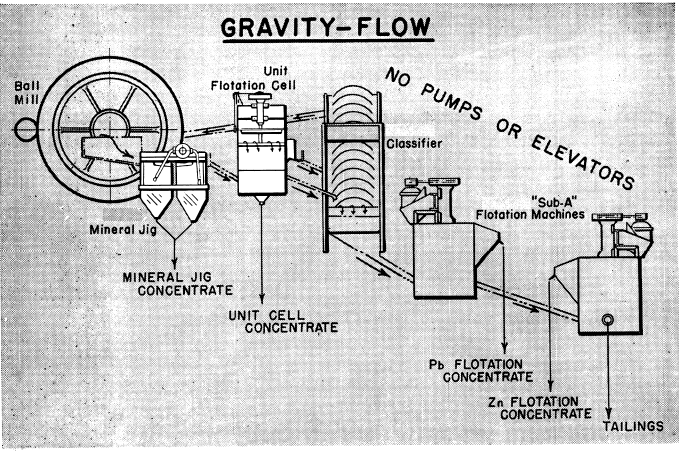

- Selective flotation which, although it has been used for a number of years, is still invaluable in treating most complex ores. The most outstanding developments in this stage of milling were improvements on the flotation machine itself. These have resulted in greater mechanical dependability, better recoveries, higher grade of products, and the elimination of pumps and elevators in circulating the pulp through the use of the gravity-flow principle.

- The most important of the two principles, the relatively new, but proved idea of removing one or more metal values from the ball mill-classifier circuit as soon as freed and as coarse as possible. This revolutionary development, although today widely known and successful in hundreds of operating plants in the field, has found great difficulty in establishing itself. This is due to most operators’ quite understandable caution when the possibility arises of interfering with the circulating load of the ball mill-classifier circuit, through over-dilution or inability of a machine to handle the coarse feed in the circuit.

The two machines, the Mineral Jig, and the Flash Flotation Cell, through their special patented design for the work of removing the mineral in the ball mill-classifier circuit, have proved highly successful. They not only remove the freed mineral but also circulate the necessarily coarse material in the circuit without complicating the system or increasing the cost.

MINERAL JIG

Probably the most outstanding reason why the Mineral Jig has been so successful in operating in the ball mill-classifier circuit is its extremely low dilution requirements. In the hundreds of installations of the Mineral Jig in the field it has always been necessary to add water to the jig tailing product for subsequent classification. Another important factor, which is often not considered, is the fact that the Mineral Jig recovers not only the coarse but the fine heavy freed mineral, as well. The fact that the jig usually operated on an unsized feed made the use of wedge wire screen of utmost importance. In the screening compartment or bed of the jig the narrowest interstices of the screen are to the top, thus allowing only that particle which may pass through this opening pass through the screen, and the result is no blinding of the screen bed.

FLASH FLOTATION CELL

The Unit Flotation Cell was designed and is now operating in installations where it recovers the floatable minerals at a coarse size and as soon as free in the ball mill-classifier circuit. The same as the Mineral Jig, this unit also recovers the fine and coarse sizes of the freed mineral. Three distinct advantages that have made the Unit Flotation Cell so successful in the field are: its low dilution requirements, which have made it always necessary to add water to the Unit Cell tailings; the machine’s ability to handle pulp of high density and to thoroughly diffuse the air; and its gravity-flow principle of handling the pulp. The fact that the Unit Flotation Cell will efficiently operate on unsized feed and coarse material is due largely to the use of the direct sand discharge.

IN GRINDING CIRCUIT

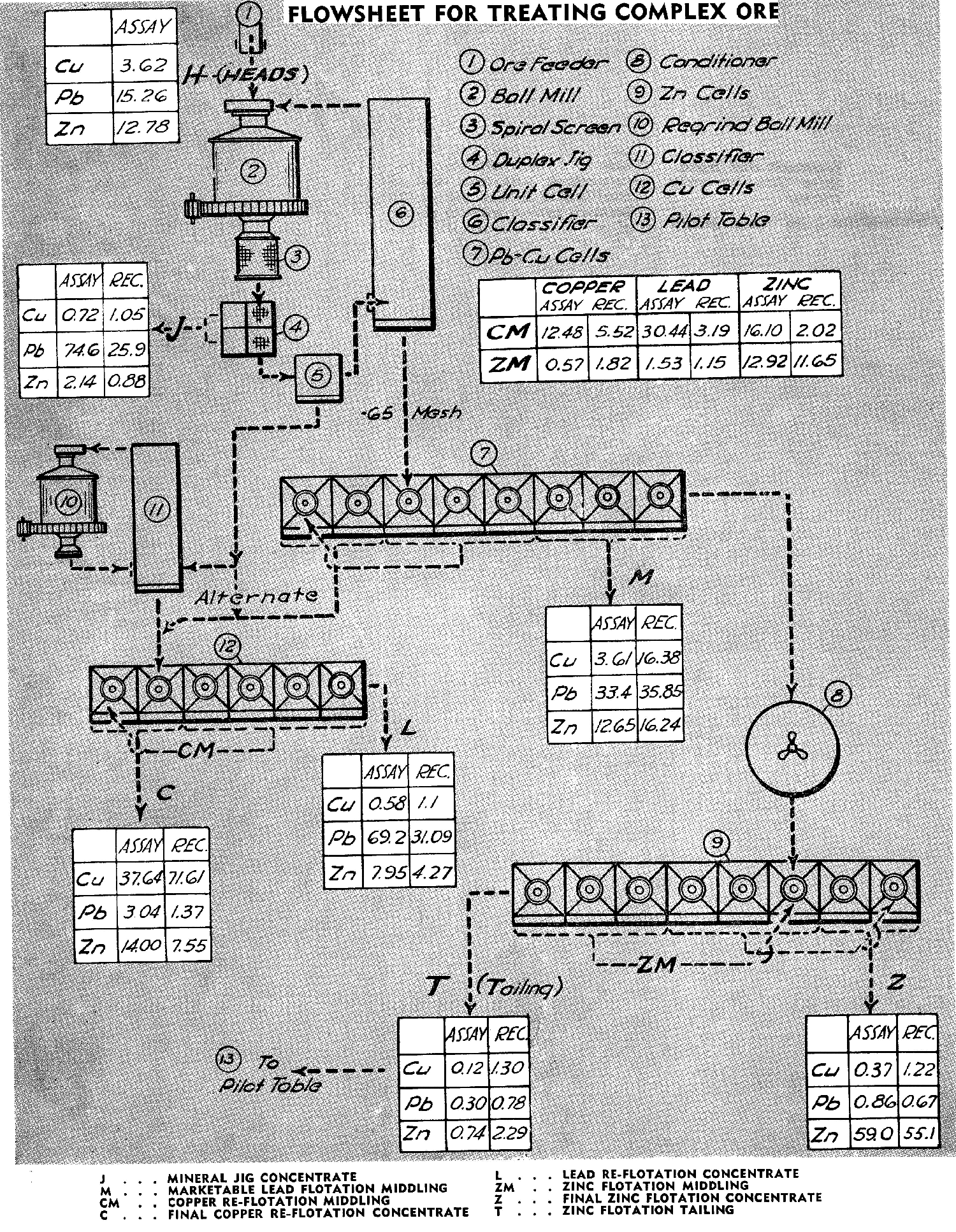

As shown in the flowsheet above, the desirable circuit is to pass the ball mill discharge over the Mineral Jig and into the Unit Flotation Cell which discharges into the classifier. In such a circuit the Mineral Jig recovers the heaviest, freed mineral which has a tendency to settle by “selective pulsation.” The Unit Flotation Cell, which next receives the pulp has the advantage of gravity-flow circulation and recovers the floatable coarse and fine mineral into a high grade product. The two machines can be installed in the ball mill-classifier circuit for removal of the freed minerals without losing any headroom. This is particularly important at this time when every mill should strive for absolute maximum production. No alterations are necessary in an existing mill flowsheet for the installation of these two units.

It is quickly apparent that when a closed ball mill-classifier circuit for fine grinding has a circulating load of from four to ten times that of the initial feed, which is true in nearly every modern ore dressing plant, this is the ideal stage of the circuit to remove the values even if only part is recovered in each pass. The installation of these two units actually lightens the load on subsequent treatment stages and simplifies the entire flowsheet in addition to yielding increased returns.

TESTING COMPLEX ORES

Ore Testing Laboratories have have the opportunity to test hundreds of ores in the past several years, and has obtained such remarkable results in using the Mineral Jig and the Flash Flotation Cell in the ball mill-classifier circuit, that the staff investigates and tries out this method in testing practically all ores.

PROCESSING A COMPLEX MINERALS

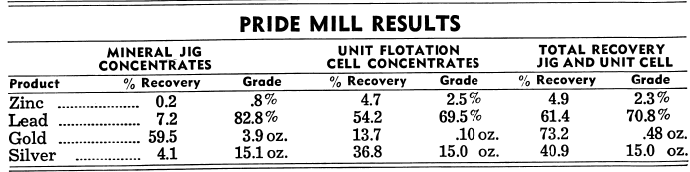

At the Pride Mill experimental test runs were made where both large and small amounts of concentrate were recovered in the ball mill-classifier circuit. It was definitely determined that when the normal tonnage produced by the Mineral Jig and the Unit Flotation Cell was reduced, it correspondingly increased the sliming of the minerals which increased tailing losses and recoveries dropped. The fine grinding also resulted in an increase in the zinc contained in the lead concentrate, and the lead in the zinc concentrate, and the fine flotation circuit was taxed to the limit. A further bad effect was the fact that the change in the operation increased the amount and cost of reagents used. The explanation of this, of course, is easy to understand when it is realized that a mineral ground far beyond its point of liberation becomes coated with slimes (colloidal coating), greatly inhibiting its floatability and the grade of concentrates.

The Ore Testing Department of Equipment Company has found that the final mill result, using the Jig and the Unit Cell in the ball mill-classifier circuit more nearly duplicates the test results, using this arrangement, than any other step in the testing of an ore. At the Pride Mill, which is operating on a complex zinc-lead-gold-silver ore, the present efficient mill results duplicate the test results in the laboratory.

A HIGHLY COMPLEX MINERAL

An extremely complex ore treatment plant can be taken as an outstanding example, as it approaches the maximum in difficult treatment problems. This was due to it being a sulphide ore of an extremely complex nature and the fact that for economic reasons commercial recoveries had to be made on five of the metals it contained copper, zinc, lead, gold, and silver.

Ore: This particular ore carried mixed sulphides associated with a siliceous gangue. Commercial values in copper, zinc, lead, gold, and silver were present, together with a considerable pyritic content. Enargite, pyrite, sphalerite, and galena, named in order of their prominence, were the principal sulphide minerals. The gold values were associated largely with the pyrite, while the silver occurried with both the galena and the enargite. Enargite is called by the miner “Black Copper,” and is the sulpharsenate of copper. The pure mineral is grayish black to iron black in color, produces a grayish black streak, has a hardness of 3.0 and a specific gravity of 4.43 to 4.45. The composition formula is 3Cu2S.As2S5 which corresponds to a composition of 48.3 percent Cu, 32.6 percent S, and 19.1 percent arsenic.

The ore had been affected to some extent by oxidation which had produced considerable water soluble salts of ferrous and ferric sulphate and zinc sulphate. When finely crushed and pulped with an equal weight of water with a pH of 7.8, the ore produced a pulp water having a pH of 5.6. Oxidation had affected the crystal surface of a portion of the galena producing a coating of lead sulphate and had also produced some free lead sulphate and lead carbonate in the ore.

Testing: Testwork done on the ore indicated that the use of the Mineral Jig and the Unit Flotation Cell in the ball mill-classifier circuit, followed by selective flotation of copper, zinc, and lead, would give the desired results. On completion of the testwork the Ore Testing Department of Equipment Company made specific recommendations for treatment methods to be used, including probable recoveries.

Jig: The operation of the Mineral Jig was well proved in this circuit where it produced a coarse lead concentrate with a high lead content and very little copper and zinc. This effectively reduced much of the lead content of the ore in the ball mill-classifier circuit and thus prevented sliming of the mineral and resultant “colloiding” of the flotation circuits.

Flash Cell: A considerable portion of the mixed enargite-galena concentrate was produced by the Unit Flotation Cell operating in the grinding circuit. In this case the middling copper-lead product at times required regrinding and provision was made for the required regrind ball mill-classifier circuit. The use of the Unit Flotation Cell in this instance short-circuited, while still coarse, a considerable portion of the mixed enargite-galena values and saved their finer grinding in the primary grinding circuit and handling through one stage of flotation with possible resultant sliming.

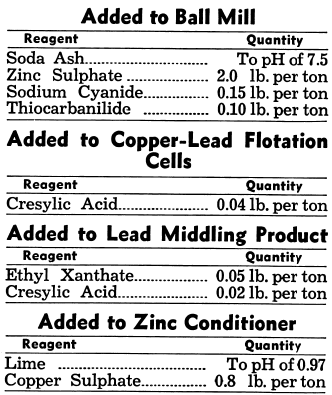

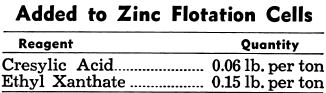

Selective Flotation: In the initial testwork regular “Sub-A” Flotation produced a mixed enargite- galena concentrate to advantage and an acceptable grade of zinc concentrate. However, galena and enargite concentrates could not be produced separately by floating in the primary circuit because too much zinc floated with the products. This led to further tests which proved that a separate lead and a separate copper concentrate could be produced only by making a lead-copper middling and treating same in a separate circuit. This was accomplished in an alkaline circuit with soda ash and using thiocarbanilide in the primary grinding circuit together with sphalerite inhibiting reagents. The copper-lead middling concentrate, after conditioning with sodium dichromate, was subjected to re-flotation and produced an enargite re-flotation concentrate and a galena re-flotation concentrate as a tailing.

Reagents: In all testwork and in every complex milling operation the selection and use of the most efficient reagents is extremely important. This particular operation, due to its exceedingly complex nature, required considerable investigation before a proper reagent balance was arrived at. For instance, the Unit Flotation Cell concentrates, due to their recovery after the Mineral Jig in the ball mill- classifier circuit, were sometimes fine enough to allow combining them with the initial copper-lead flotation concentrate. This combined concentrate was then cleaned once with soda ash, cyanide and zinc sulphate. The cleaned concentrate was then re-floated after conditioning in one cell of the copper flotation section with 1.0 pound per ton of sodium dichromate. The resulting copper re-float was then again cleaned once by re-flotation with additional sodium dichromate.

Other reagents used were:

Flowsheet: The layout of the final flowsheet was such as to fulfil two specific requirements of the latest metallurgical knowledge and milling economics:

- Recover the values just as thoroughly and rapidly as practicable, and as coarse as possible, preferably in the grinding circuit, thus eliminating much equipment for grinding and recovery of fine values in later stages.

- Design a simple flowsheet to provide maximum flexibility and still maintain the highest economic efficiency.

Both the Mineral Jig and the Unit Flotation Cell were developed in large concentrators in Canada and the United States and in collaboration with leading metallurgists and mill-men to fill the requirements of both 1 and 2. Actual operation of these units in the field plus extensive tests conducted by the Ore Testing Department of 911metallurgy Corp have proved conclusively that either unit individually, or both units in series, will enable mills to make high-grade recoveries on the majority of even the most complex ores. These results are proof of the importance of the first rule in metallurgy, “When your mineral is free, take it out,” particularly in treating today’s complex ores.

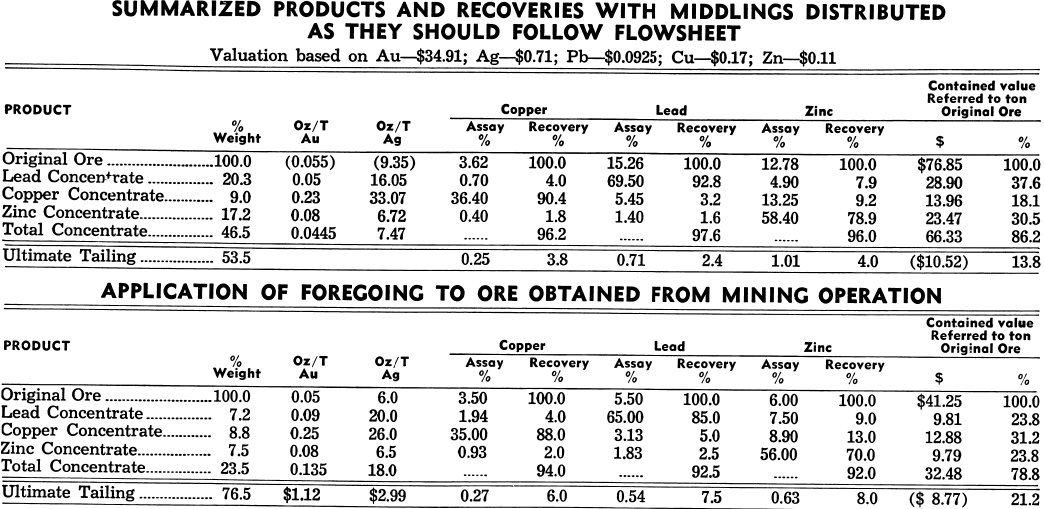

Note. The distribution of the various middling” products of this study is based on the theory (that has been proved in practice to be satisfactory for such free milling ores as this) that the Middlings of any metal circuit can be distributed to the Concentrates and Tailings of that circuit on basis of production of concentrate of equal grade (for principal metal) and a tailing of analysis twice that of circuit in which the middlings were made.

Mineral Processing and Extractive Metallurgy Flowsheet

Source: This article is a reproduction of an excerpt of “In the Public Domain” documents held in 911Metallurgy Corp’s private library.