Rock Crushing Process in Mining

Table of ContentsRock Crusher TypesJaw CrusherGyratory CrushersImpact CrushersRoll CrushersCone Crushers Let’s follow a rock through a crushing cycle to see what variables will have to

Table of ContentsRock Crusher TypesJaw CrusherGyratory CrushersImpact CrushersRoll CrushersCone Crushers Let’s follow a rock through a crushing cycle to see what variables will have to

Crusher are used to reduce the ore in size, the purpose and the responsibility of the crusher operator is to operate that crusher in such a

For easy of Operation & Maintenance, all Rock Crusher Lubrication System include their own monitoring devices, SIGHT GLASSES or VIEW PORTS in the reservoir for

The lubrication of Gyratory crushers may be one of the special problems that the Jaw crusher isn’t as readily exposed to. This crusher, because it

The Gyratory Crusher is made up of six main components, Base, Main frame and concave liners, Drive assembly, Mantle, Spider arm assembly, Oil system. It

To accomplish this reduction in size takes several steps or stages of crushing and grinding. Primary crushing is the first of these stages. Generally speaking

Let us talk about Basic conveyor safety as it is just like being around all moving equipment will be guards of one type or another.

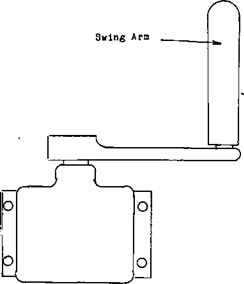

The other switch I mentioned was a MISALIGNMENT switch. This is a manual swing arm that is placed beside the conveyor belt. If the belt

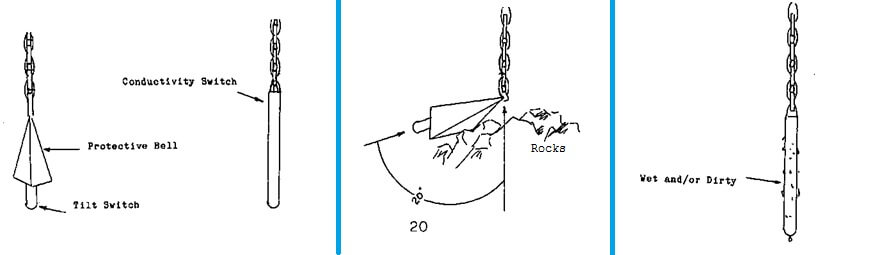

A Plugged Chute Detection Probe is an emergency switch that will shut down the equipment should a transfer chute “become plugged. There are two common

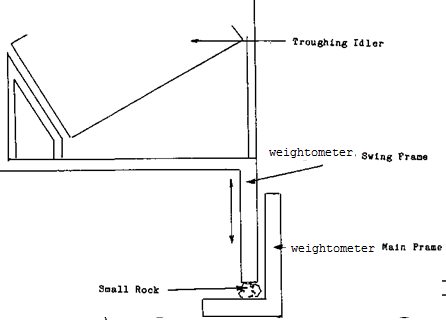

Belt Conveyor weightometers are required to accurately weight and chart the tonnage throughput. An operator is able to catch many problems that are developing simply by