Ultra-Fine Grinding and Classification

Fluid jet mills-employing a compressible fluid to grind materials to the sub-sieve range, was developed in the early 1930’s, and the subsequent acceptance of these

Fluid jet mills-employing a compressible fluid to grind materials to the sub-sieve range, was developed in the early 1930’s, and the subsequent acceptance of these

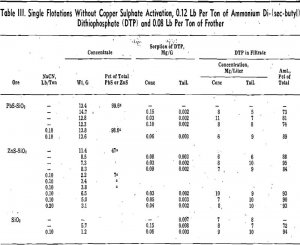

Dithiophosphate collectors are commonly used in the flotation of sulphide minerals. Studies of the interaction of a typical dithiophosphate collector with galena surfaces have been

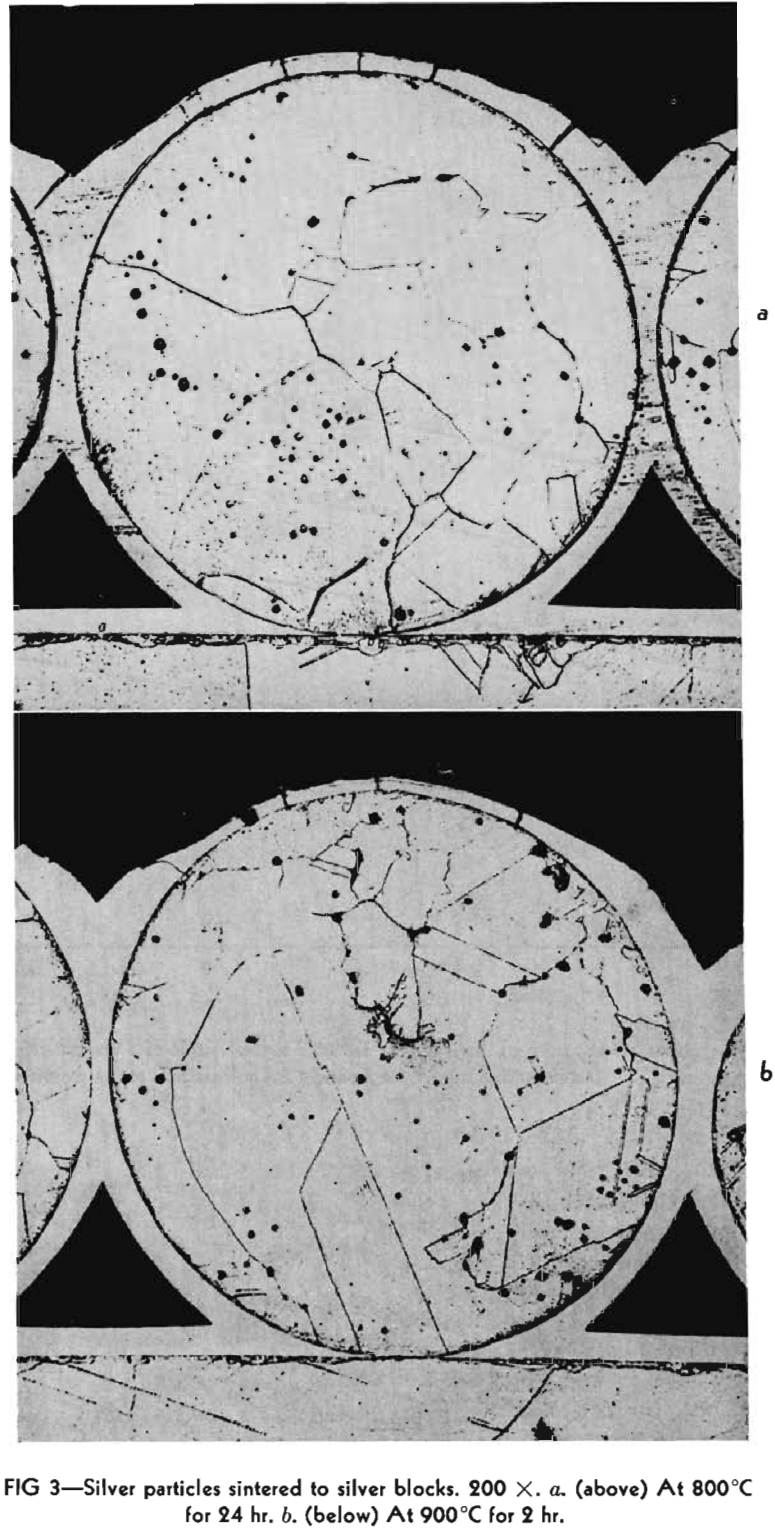

Two particles in mutual contact form a system which is not in thermo-dynamical equilibrium, because its total surface free energy is not a minimum. If

In U. S. underground mines concrete work is not widely used. Timber and steel are cheaper, and there are few serious water problems. But in

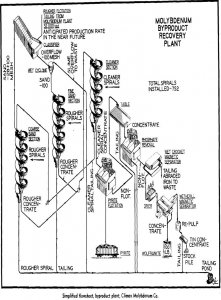

Grinding Practice—These tests were run in the 9 ft diam by 8 ft long grate discharge ball mills at Climax. Each mill functions in closed

Iron king mine, producing gold-silver-lead-zinc ore, is 10 miles east of Prescott, Ariz. At present the 1806 level is being developed. The echelon pattern of

Since it was introduced in 1943 to recover chromite from Oregon beach sands, the Humphreys spiral concentrator has proved successful in several fields of wet

An emulsion is a two-phase system consisting of two incompletely miscible liquids, the one being dispersed as finite droplets in the other. The dispersed liquid

Cobbing, as used in this paper, refers to coarse dry magnetics separation. It is applicable when, by its practice, plant cost can be reduced or

Idlers: Due to the efforts of the Conveyor Equipment Manufacturers Association, the basic idler elements—idler roll wall thickness, bearing sizes and shaft sizes—have been standardized