Scrapped Starter Motors & Alternators Recycling

There are two principal methods in use for processing the 8 million cars that are scrapped annually in the United States. About one-half of the

There are two principal methods in use for processing the 8 million cars that are scrapped annually in the United States. About one-half of the

The minntac complex is a facility for production of iron ore pellets located on the mesabi range at mountain iron, minnesota. It consists basically of

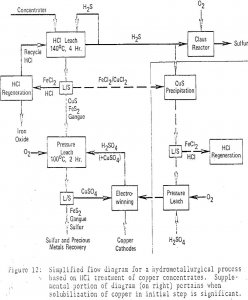

Experimentation with chalcopyrite concentrate in dilute hydrochloric acid, under reflux conditions (in Pyrex flasks) and with an inert purge gas, revealed substantial amounts of H2S

The kaolin development brings together for the first time four concepts that make practical large scale use of high extraction magnetic filtration (HEMF). These include

The passage of an ore pulp through the froth flotation process results in the production, after dewatering, of a finely divided concentrate. This intermediate product

The normal practice for processing complex sulphide ore has been to grind with steel balls and/or rods in steel mills before flotation. Little thought had

The rotary drying system consists of a final concentrate thickener to dewater the slurry to about 60%-70% solids; a vacuum filter (disc or drum) with

‘Yellow cake’, so named because of its inherently bright yellow color, is a finely divided precipitate that can be formed after the leaching step when

A unique type of grinding mill liner has been developed by Waagner-Biro A.G. of Austria. This liner system, termed an angular spiral lining (ASL), was

Metallurgical processes involving the use of cyanide such as gold cyanidation, metal plating and flotation, generate effluents containing cyanide and cyanide in complex combinations with