Carbon-In-Pulp Process Examples

There are no major innovations in any of these plants. In fact, Australia is really only beginning to get started in CIP research and in

There are no major innovations in any of these plants. In fact, Australia is really only beginning to get started in CIP research and in

The effects of operating variables on water transport to the overflow, classification of hydrophilic particles and the recovery of copper and molybdenum from a low-grade

Rhenium is industrially recovered all over the world as a by-product of molybdenite processing. There are no separate deposits of rhenium minerals. Molybdenite concentrates, produced

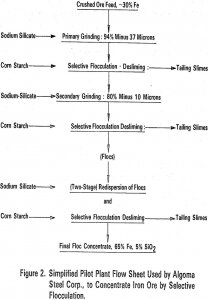

In the upgrading of finely-disseminated iron ores, selective desliming is the critical step which must be controlled in order to achieve efficient flotation. A prerequisite

As part of our mission to investigate technology options for the development of domestic mineral resources, conducted tests aimed at separating the copper-nickel values in

Selective flocculation utilizes the differences in the physical-chemical properties of the various mineral components in the mixed suspension. It is based on the preferential adsorption

Dewatering of the fine clean coal fraction, — 28 mesh (595 microns) represents one of the most difficult and costly separations in typical plant circuits.

A measured pulse of energy is sent into the bolt by a piezoelectric transducer, and the instrument listens for reflected energy. Where the bolt is

The discovery of rhenium on the ion exchange resin used at the uranium in-situ leach operations at Palangana (Texas) led to a laboratory study on

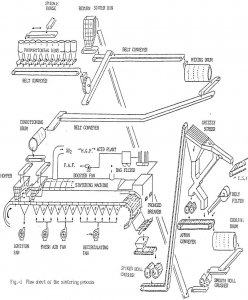

The sintering process for the preparation of raw materials to be fed to the Imperial Smelting Furnace (I.S.F.) is rather diversified in its characteristics. In