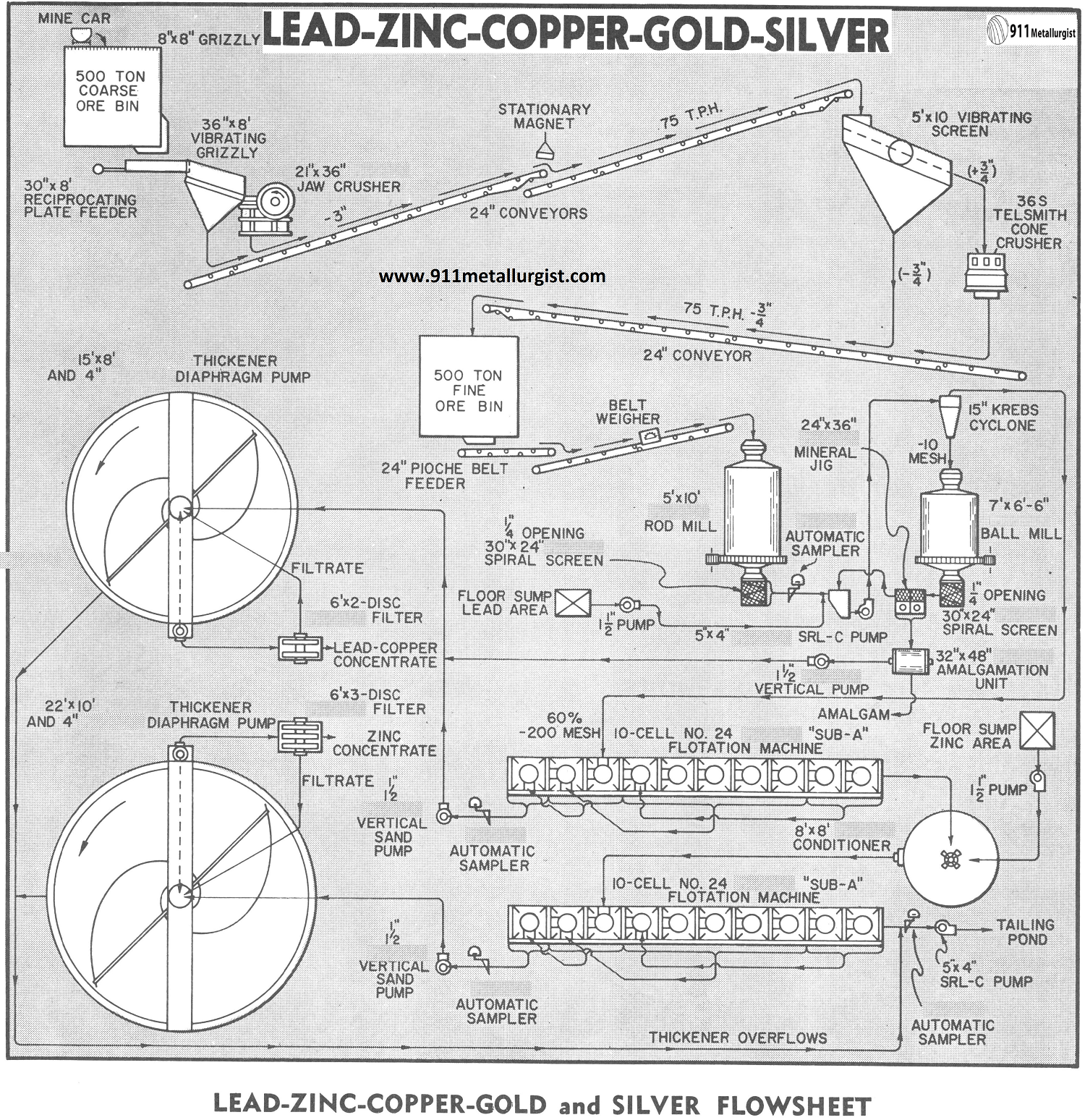

The flowsheet in this study was designed to treat 500 tons per day of a complex base metal ore containing gold and silver values. The presence of free gold offers opportunity to recover these values in the grinding circuit so that the gold could be amalgamated, and marketed directly to the mint. The ore as mined is very wet and sticky and presents certain handling problems.

The Lead Zinc Copper Flotation and Separation Circuit

Every effort is made to recover the minerals as soon as free. Over-grinding causes slime losses which are both unnecessary and costly. The flowsheet is designed for a compact mill of a size that provides economical treatment at this tonnage.

Crushing Plant

The wet ore is delivered to the coarse ore bin directly from the mine and dumped through a grizzly to prevent any large rocks from lodging in the bin and causing subsequent problems in feeding the rock crusher. The stored coarse ore is crushed in two stages to produce a ¾-inch product. The reciprocating feeder, overhead eccentric-type jaw crusher, and oversize vibrating screen were selected to alleviate problems in handling a wet and sticky ore. All chutes and transfer points should be of maximum slope to minimize sticking. In some cases chutes should be lined with “Teflon” if the sticky ore is a severe problem.

Grinding Circuit

The ¾” ore is ground to 60% minus 200 mesh using two stages of grinding. The crushed ore is reduced to approximately 10-mesh in open circuit using a Rod Mill. This product is pumped to a cyclone using a SRL-C Pump. The cyclone underflow represents feed to the Ball Mill which operates in closed circuit with the same pump-cyclone installation. The cyclone overflow is the feed to flotation.

A duplex Mineral Jig is installed between the ball mill and pump-cyclone. The jig recovers the free gold and also produces a high grade lead concentrate that is very low in zinc content. After amalgamation of the jig concentrate using a Amalgamation Unit, the gold is recovered in the form of amalgam and the residue is considered as a final lead concentrate. Recovery of the gold as amalgam minimizes problems encountered in assaying mill products containing erratic free gold values and increases the over-all gold recovery.

https://www.911metallurgist.com/sequential-cu-pb-zn-flotation

Flotation Plant

A complex sulphide ore of this type requires a high degree of selectivity in the flotation process. The lead and copper must be removed in bulk as a mixed concentrate and then the zinc floated as a separate concentrate because of marketing requirements. A further separation of the lead-copper into their respective products by flotation is often economically advantageous if the crude ore contains 0.8% copper (16 pounds per ton) or more. In the case of this study, it is assumed that a separate lead-copper circuit is not warranted.

The flotation section consists of two 10-cell “Sub-A” Flotation Machines, one for the lead-copper and the other for the zinc. The launder arrangement and pulp flow is the same for both machines and provides double cleaning of the rougher concentrates. This intricate arrangement of pulp flows is accomplished without the use of pumps and is possible with the distinctive cell-to-cell design of the “Sub-A” Flotation Machine. A Conditioner is included between the two banks of flotation machines for activating the zinc and preparing it for flotation.

Conventional reagents are used in the selective flotation separation. These consist of zinc and iron sulfide depressants which are added to the grind and a collector and frother for the lead-copper sulfides. The zinc is floated with additional quantities of a collector and frother after conditioning with lime and copper sulfate. The pH of the lead circuit is approximately 8.0 and the zinc is 10.5 to 11.0.

https://www.911metallurgist.com/sequential-copper-lead-zinc-flotation

Concentrate Thickening and Filtering

The two concentrates are thickened using Spiral Rake Thickeners. The thickened concentrates (thickener underflows) are metered from the thickeners using Adjustable Stroke Diaphragm Pumps which feed the two Disc Filters.

The lead-copper concentrate also contains the major part of the gold and silver values present in the ore. The high gold recovery possible by a flowsheet of this type is augmented by the Mineral Jig which recovers the coarse free gold. The amalgamation residue, which is high grade lead, is combined with the lead-copper flotation concentrate in the thickener.

Sampling

Automatic Samplers are used to sample the feed, lead-copper concentrate, zinc concentrate, and final tailing for accurate control of mill operations.

Summary

This flowsheet stresses simplicity of operation consistent with maximum metallurgical efficiency and optimum economy.

Locked cycle flotation tests at the Process Testing Laboratory are instrumental in developing flowsheets and laboratory results that can be duplicated in full-plant operation.

Source: This article is a reproduction of an excerpt of “In the Public Domain” documents held in 911Metallurgy Corp’s private library.