This section of the Paper deals with the abrasive character of rocks affecting crushing machinery. The investigation has followed two courses, firstly, an analysis of the existing data relating to the testing of road-making stones from its bearing on the abrasive wear of crusher-parts, and secondly, an experimental investigation into the correlation of abrasive wear as encountered in practice, and the physical and petrological characters of rocks.

STEEL & ROCK WHICH INFLUENCE WEAR

In the case of metals the property required to produce resistance to wear is a combination of hardness and toughness in the maximum practical development. In the materials crushed, the greatest resistance to disintegration is given by the rock with the optimum combination of these same properties. In the case of metals the kind of hardness manifested varies according to the form of stress to which the metal is subjected, and is generally referred to in terms of some distinctive method of determination, either elastic (sclero- scope) or deformation (Brinell, etc.). Mineralogical hardness, applicable to the constituents of rocks, on the other hand, is regarded as the resistance offered by a smooth surface to abrasion. It is measured by a scratch test in which particles of the softer substance are torn away by the harder. An ordinary diamond hardness-test as applicable to metals does not give a measurable impression with rocks, but merely causes shattering of the neighbouring brittle crystalline material. Accordingly the most satisfactory means of expressing hardness, namely by a complete stress-strain curve, is not applicable to rocks.

“ Hardness ” as determined in the testing of road-making stones, is measured by the Dorry machine, in which the material to be tested is pressed against a rotating steel disk, an abrasive, quartz, being fed on to the disk. The test is generally known as the abrasive test, but its interpretation as such must be entirely confined to the problem of road-service. It does not define sufficiently the abrasive character of stone in relation to wear of metal parts in crushing-machinery.

The diamond-scratch test for the determination of the hardness of rocks was found to be impracticable. The width of the scratch in rocks was found to vary with the orientation of the crystals, the grain-size, the degree of decomposition and the state of finish of the surface, although a perfectly satisfactory relationship could be traced between the minerals of Moh’s scale and the width of the scratch. The machine used was one previously employed by Sir Robert Hadfield, Bart., M. Inst. C.E., and Mr. S. A. Main in researches on the hardness of metals.

Toughness in metals is deduced from the tensile strength, the elastic limit, and the ductility. Toughness may also be defined as the total energy per unit volume that can be absorbed up to rupture, and is given by the area of the entire stress-strain diagram. Manganese steel (11-13 per cent.) has been proved from extensive practical experience to give extreme durability in many classes of operation where resistance to abrasive wear is required. It has, as an outstanding characteristic, a high degree of toughness combined with an acquired hardness produced by deformation. It also has considerable resistance to impact.

In the case of rocks, toughness is determined solely by impact. The machine used was devised by Mr. L. W. Page, and is built on the pile-driver principle. A standard weight is dropped from successive heights on to a test-piece carried on a block of standard inertia. The height in centimetres of the blow causing rupture of the test- piece represents the toughness of the specimen.

MECHANISM OF ABRASION

In crushing, the abrasion occurs chiefly as direct rubbing under the interposition of an abrasive in the form of free particles, either of the metal or the rock, chiefly the latter. It becomes complicated by variations of physical properties, dimensions and distribution of the free abrasive agent on the wearing surface of the metal. The principal factor affecting durability is the surface-pressure exerted. In certain cases this may be favourable to the metal, as, for instance, in the case of manganese steel. In an investigation of abrasion of metals, Mr. Main has shown the importance of acquired hardness by work-hardening in abrasive wear. Without work-hardening, metals can only tend to show the resistance to abrasion which is commensurate with the influence of the initial hardness.

Generally, the wear of metals in this connection depends primarily upon the character of the abrasion, and particularly upon the nature and distribution of the free abrasive. Other significant factors are speed of relative motion, contact-pressure, temperature, time and surface-conditions.

No successful method has been developed of testing materials for use in crushing machinery. Most methods that have been tried have produced a condition of excessive abrasion, and have not reproduced the work-hardening conditions usually met with in rock- crushers. Results have accordingly not been consistent with those encountered in the crushing of the rock in the quarry or mine. But accurate field records are seldom available. In many installations crushing is done in two or more stages, and intermediate screens are used for taking out sizeable materials, thus relieving the crusher of unnecessary work. Also the plants are often worked in closed circuit, and the oversize automatically returned to the crushers. Under such conditions, the only reliable figures of tonnage are obtained from the input to the primary breaker. The amount passing to the other machines varies with the setting and size of feed.

ANALYSIS OF EXISTING DATA RELATING TO ROAD-MAKING STONES

The Authors have correlated the physical and petrological data available with their practical experience of abrasive wear in crushing machinery, Through Dr. Bernard Smith and the late Dr. H. H. Thomas, of H.M. Geological Survey, they have been able to obtain additional petrological data relating to some of the published mechanical tests. The conclusions from this analysis confirm the results of the experimental data. In general, only those tests have been included which from experience can be regarded as germane to the subject, namely the direct crushing test, Page impact, Dorry abrasion and dry attrition (Deval and Lovegrove) tests. The Lovegrove attrition testing apparatus consists of three hollow rotating cast-iron horizontal cylinders, fitted with angle-iron ribs, which give in effect a combination of attrition and slight impact. The Deval machine has smooth inclined cylinders on a diagonal axis. In each case the percentage wear is deduced from the weight of dust of a specific size obtained from a given number of revolutions at a specified speed on material of fixed grading. The comparison of these two methods of determining wear by attrition has been made on the basis of the formula proposed by Mr. R. G. C. Batson, M. Inst. C.E., and the late Mr. J. H. Hyde, Assoc. M. Inst. C.E.

The Authors have correlated the earlier classical work of Messrs. E. J. Lovegrove, M. Inst. C.E., and L. W. Page, the petrological studies of Sir John Flett and Mr. J. A. Howe, and the records of tests carried out at the National Physical Laboratory. An interpretation of the mechanical properties can be made generally in terms of mineral composition, mode of origin and structure. The following is a summary of the salient features indicated in the diagrams, Pigs. 36 to 48, Plate 1.

Granites, Porphyries and Limestones.—These have been correlated in Figs. 36 to 39, Plate 1. The general trends of relationship have been indicated by the lines marked on the diagrams. Dominant features are :—the definite relationship shown between the crushing strength and the impact (Fig. 36, Plate 1), when classified into groups indicated by the lines AB and CD ; the extremely favourable position as regards hardness and toughness of the porphyries; the low impact and severe attrition of the limestones.

In the granites, the resistance to grinding, as indicated by the Dorry machine, is generally high and uniform, but there may be considerable variation in resistance to impact, or toughness. No. 298, with a high impact value, is a diorite (Colwall Park, Malvern), this type of rock usually being fine-grained with augite, biotite and hornblende, which are often fibrous and thereby give impact strength to the rock. The gneisses being igneous or sedimentary rocks that have been subjected to alteration, re-crystallization and folding, have for this reason lines of weakness, giving low toughness (Nos. 241, 243, Inchberry and Balchraggan, Inverness).

The porphyries have a structure and composition which, from the analogy of the grinding-wheel, discussed later, would be expected to reveal mechanical properties of a most abrasive nature in crushing- machinery. Such is found to be the case. They are characterized by large porphyritic crystals of quartz or felspar, and sometimes of biotite, augite or hornblende, cemented into a fine-grained matrix, which has frequently a particularly tough structure.

In certain cases the attrition loss (Lovegrove) bears a direct relation to the Dorry value for the same values of impact, instanced by Nos. 343, 172, 221, 178 of Mr. Lovegrove’s series taken from the base of the triangle in which they are grouped in Fig. 37, Plate 1 ; the comparison is made in Table I.

At the base of this triangle in Fig. 37, Plate 1, it will be noted that there are four porphyries, Nos. 24, 29, 31, 32, from the National Physical Laboratory list, which show a gradual increase of impact, a remarkably uniform and high Dorry abrasion and crushing-strength (with the exception of No. 31, which gives somewhat lower values), but an increasing attrition in the direction opposite to the general improvement in physical properties. There are also inexplicable variations in water-absorption, which are indicated in Table II :—

At the Authors’ request Dr. Thomas examined the rock sections in the official collection relating to these cases in order to determine if these variations could be explained by the composition and structure, and his conclusions are as follows :—

No. 31 contains small crystals of albite in a quartz-felsite fine-grained matrix, and the tests seem consistent with type.

No. 32 is a fragmental rock, well cemented, with close texture and fine grain. There is some interstitial calcite, which points to a somewhat cavernous condition of the rock, the only explanation of the abnormal water-absorption.

No. 24, a rather coarse quartz-biotite-porphyry, is a normal igneous rock, and the tests seem consistent.

No. 29 is a moderately coarse porphyritic quartz-albite-ceratophyre, allied to the quartz-porphyries.

In the case of the last two rocks, the presence of larger crystals would probably account for the larger attrition values.

The low mechanical properties of the limestones are due to the softness and ready cleavage of the constituent mineral, calcite. The abrasion (Dorry) varies over a wide range from 18.4 to 8.8. Sir John Flett and Mr. Howe have shown that the characters of limestones as revealed by the Lovegrove attrition test varied with geological age, which governed the conditions of formation, and that the toughest limestones were those which were the least crystalline, and consisted of broken fossil fragments cemented by secondary calcite. Practical experience with these rocks in crushing indicates that there is very little wear on jaws in breakers.

It will be noted that No. 105, a limestone from Gloucestershire, is remarkable for its toughness, and would be expected to have an interesting structure. This rock is an organic limestone, much veined with calcite with a fine calcareous dolomitized matrix. There is no obvious reason for the toughness of this rock, unless it be the dolomitization that has generally affected the rock.

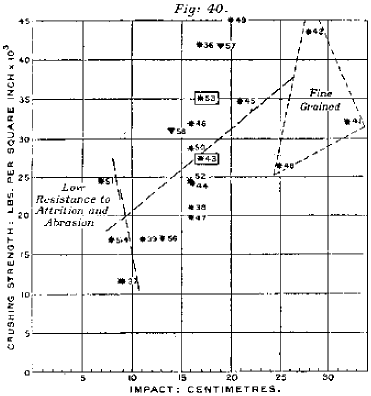

Basalt.—The class covers intrusive igneous rocks essentially of basic chemical composition, and containing as dominant minerals plagioclase felspar, augite and olivine. They are specially interesting from a crushing standpoint because of their wide distribution, and varied range of composition, structure and degree of alteration. An analysis of certain rocks reported in the National Physical Laboratory tests (Nos. 36, 38, 43, 46, 47, 50, 52, 53) shows that for a number of dolerites and basalts of the same toughness there was a range of values for both attrition (Deval) and abrasion (Dorry) of apparently inexplicable confusion. When, however, the crushing-strength was compared with the wet attrition and water-absorption (Fig. 44, Plate 1), excluding the rocks with a dominant content of olivine, namely, Nos. 50,52 and 53, there was a direct relation between the absorption value and the crushing-strength, thereby indicating that the porosity produced by decomposition was mainly responsible for the variation in direct crushing-strength.

Two of these rocks with abnormal wet attrition values, namely, Nos. 43 (quartz-dolerite, Perthshire) and 53 (olivine-tholeiite, Angus) were referred to Dr. Thomas. They had wet attrition values (percentage wear) respectively of 7.8 and 11.5. No. 43 proved to be a good sound quartz-dolerite with a strongly developed lath structure. From the structure it should be hard, tough and not porous. There is a small amount of interstitial matter, but the explanation of the higher wet attrition value is not evident. No. 53, on the other hand, is a fine-grained rock with small decomposed crystals of olivine, augite and plagioclase in a glassy base. The high water-absorption (1.49) is possibly due to the porous nature of the decomposition products and also possibly to fissures in the base.

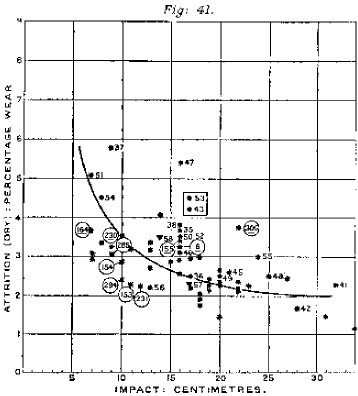

From a critical examination of the tests of Messrs. Lovegrove and Page (Figs. 41 and 43, Plate 1), it is apparent that where the impact-value is constant the rocks showing the lower Lovegrove attrition and Dorry abrasion are altered and decomposed. Taking values for five rocks falling on either side of the curve of general relationship between Dorry abrasion and Deval attrition (Fig. 42, Plate 1) namely those of low Dorry abrasion, Nos. 153, 231, 294, 154, 230, as against those of high Dorry abrasion, Nos. 155, 305, 285, 6 and 164, the average absorption-values for each group are respectively 0.33 and 0.21. The average toughness-values corresponding to these are respectively 10.4 and 14. The toughness in the second set is very variable (Figs. 41 and 43, Plate 1).

There is reason to believe that the Dorry abrasion-test is not of critical significance in this problem, and that the wide variation of Dorry values in these rocks has little bearing on their behaviour in crushing.

Metamorphic and Sedimentary Rocks.—Rocks of Classes G and H of the National Physical Laboratory classification, namely quartzites and grits, are included for convenience in Figs. 45 to 48, Plate 1, with hornfels, andesites and metamorphic rocks of the investigations of Sir John Flett and Mr. Howe. The essential features of the hornfels and metamorphic rocks arise from their origin, and subjection to metamorphic agency, whereby they may have become recrystallized and foliated, and there may have resulted a dense mechanically strong structure, or a weak fissile character. The composition and structure of the andesites is such as to produce rocks of great toughness (Fig. 46, Plate 1), the only rocks having low toughness, Nos. 161, 50 (Forret and Foodie respectively, Cupar, Fifeshire) revealing evidence of mineralogical decomposition.

The distribution of the quartzites in the diagrams shows the closest grouping as a class, relations arising from their relatively uniform composition. They have a moderately high toughness, high resistance to Dorry abrasion and attrition, and a remarkably uniform relation between impact and crushing-strength. They are generally abrasive in the practical sense in crushing-machinery, provided the impact-value approaches 15 and over.

In the grits the cementing material largely governs the properties, but since the nature of the aggregation and the bond varies so widely, the mechanical properties of the rocks considered do not show any characteristic relationships.

Rocks Nos. 86, 87, 78 and 91, which, from Figs. 45 and 46, Plate 1, are of opposite properties as regards impact, attrition, and crushing-strength, were referred to H.M. Geological Survey for evidence of petrological characters. Nos. 86, 87 have approximately the same Dorry hardness-coefficient, the same attrition, but widely different impact and crushing-values. The petrological examination indicates that 86, the stronger and tougher, is a coarse-grained sandstone, loosely cemented with a good deal of sericitic matter in the interstices, whereas 87 is a fine-grained sandstone with the quartz grains almost all the same size. The cement appears complete, and is mainly secondary silica. A high water-absorption figure of 1.87 must be due to water entering along bedding-planes or other planes of lamellation. Nos. 78 and 91 have the same toughness, but different values of attrition and abrasion-hardness. No. 78, the harder, is coarse and irregular in grain. There is more interstitial matter and the cement does not appear so strong. No. 91 is a fine-grained sandstone with constituent grains not tightly packed. It has a sericitic matrix. Contrary to the evidence of the igneous rocks there are accordingly in these sedimentary rocks wide divergences in properties not readily related to distinguishable characters of the rocks. The character of the cement is the overruling factor of the properties, which is only revealed by the physical tests.

Dr. B. H. Knight, Assoc. M. Inst. C. E., has made an extensive study of various types of rock encountered during the construction of the new Glencoe road in Argyllshire, and has published a classification of serviceability of road-making stones on the basis of petrological study. Particular stress is laid upon the occurrence of “ incipient fissuring ” due to the phenomenal faulting of rocks encountered in the district surveyed.

Minerals.—Minerals constitute a simpler problem, because the heterogeneity of aggregation of many dissimilar minerals, and the influence of structural planes of weakness in rock masses arising from geological agents of change, are generally absent.

The Authors are indebted to Dr. L. J. Spencer for suggesting the investigation of the properties of nephrite in connection with their study of the specific influence of toughness. The subject is referred to in the experimental section, p. 89.

Most natural minerals are brittle, but there are a number that develop increased toughness with modification of mode and fineness of crystallinity. Associated with this production of toughness there is introduced a greater resistance to abrasive wear, and accordingly an increase in the range of utility of the mineral. Thus the diamond, when found as a single crystal; has a highly perfect cleavage and is brittle, whereas its variety, carbonado, is without cleavage and is described as noncrystalline. That is to say its degree of crystallinity is beyond the resolving power of the microscope. Carbonado is used in diamond rock-drills, whereas crystalline diamond would shatter in such use. Quartz, which is capable of being brittle, is tough in the cryptocrystalline form, examples of such occurrence being agate, a variegated chalcedony, and flint. The mineral is highly abrasive, and the property is utilized in the ceramic industry for grinding purposes. Garnets are brittle when occurring as coarse and well-defined crystals, but when cryptocrystalline, as from the Adirondack mountains, the mineral is used as an abrasive. Augite, as prevalent in many igneous rocks, has a distinct system of interrupted cleavage-cracks. Jadeite, however, a fibrous foliated variety of monoclinic pyroxene, is extremely tough, and is highly prized, particularly amongst eastern nations, as an ornamental stone suited to fine workmanship. Sillimanite, occurring with corundum as fibrolite, another fibrous massive rock, is hard and tough, and the Authors have experienced its severe abrasive action in crushing machinery. In crushing emery variations of abrasiveness according to the degree of toughness developed have been noted. The value of toughness in governing abrasive qualities is also instanced in the application of “ abrasive temper ” in the production of artificial corundum.

EXPERIMENTAL STUDY OF ABRASIVE ROCKS

For the experimental study of abrasive wear in crushing, data have been collected from field experience of rocks known to give severe abrasive wear, typical cases have been selected in a range of varying character, and their behaviour in service correlated with their composition, structure and physical properties.

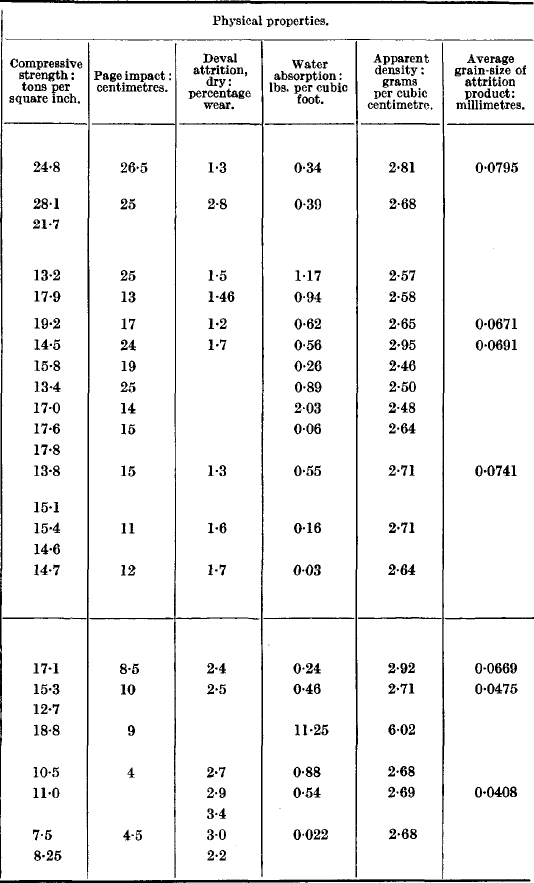

Table III gives a series of rocks approximately in their order of abrasiveness. All the rocks in Series I are known to be more or less strongly abrasive in practice. The materials in Series II are of less or uncertain severity.

The following is a discussion of the correlation of these features, the mechanical tests indicated in Table III, and the composition and structure as determined from petrological examination.

CORRELATION OF STRUCTURE AND MECHANICAL PROPERTIES

Generally a relationship is revealed between mineral composition, structure, mechanical properties and abrasive character under crushing. The abrasiveness depends primarily upon the presence of a fine-grained matrix or cement, or the equivalent interlocking or morticing-together of the constituent crystals, and the manner in which defined crystal-aggregates are oriented in the matrix. The natural hardness and toughness of these defined crystals is an accessory factor. A tough interlocked structure is noteworthy in the following rocks detailed below—Penmaenmawr granophyre(R.F.831), Penlee diabase (R.F. 826), Magheramorne basalt (R.F. 769), and Northumberland Whinstone (R.F. 824). Porphyritic crystals in a fine-grained matrix operate in abrasion in the manner of the grinding- wheel, the analogy of which is discussed later. Hard cutting-edges are held in a tough matrix. The Crarae granite (R.F. 800) is an illustration of the case. The rocks of lower mechanical properties and less abrasiveness are shown in the rock sections to have, as contributory factors, an absence of morticed structures, coarse grain, occurrence of fissures or veins, the presence of softer products of alteration, or, as in the case of limestones, a distinct change of constituent mineral.

Penlee (Cornwall), Gwavas Quarry, R.F. 826.—A contact-altered albite-diabase composed largely of albite felspar in interlocking crystals with chlorite, biotite and hornblende. The great strength and toughness of the rock is due to the nature of the structure and to the recrystallization produced by contact metamorphism.

A marked keying of the crystals into one another is to be noted. The alteration-products occur in veins and irregular aggregates of finer crystals surrounding the boundaries of the dominant crystals, frequently penetrating them.

Magheramorne, Northern Ireland, R.F. 769.—A fine-grained non- porphyritic basalt. This has fine-grained interlocking crystals of augite (present as small elongated prisms and rhombs in the groundmass) and laths of plagioclase. The structure has the appearance of inter-penetrating fine rods oriented in all directions, and is consistent with the high crushing-strength and toughness found. It contains also finely divided iron ore, and a little interstitial matter, mainly consisting of decomposition-products. The iron oxide occurs in the ground-mass between the rod-like crystals, and is to be associated with the rather high value for the Deval attrition.

Argyllshire Granite, R.F. 800.—A biotite-hornblende-porphyrite. The rock is typical of the occurrence of porphyritic crystals in a fine-grained ground-mass; good physical properties accompany this structure. It is definitely known to be strongly abrasive in crushers.

Bonawe Granite, R.F. 827.—Of high crushing-strength and

moderately tough, it is a high-grade granite and defined as a fine-grained biotite-granite. The constituents, orthoclase, plagioclase, and quartz, are securely interlocked.

The size of the grain is fairly uniform and intermediate between that of the fine-grained ground-mass of the Crarae rock (R.F. 800) and of the coarser Cruachan granite (R.F. 828).

Northumberland Whinstone, R.F. 824.—The typical quartz-dolerite of the Whin Sill, it is composed of two varieties of augite, plagioclase, and iron ore as black isotropic masses. A little interstitial quartz and decomposition-products are present. The grains of the dominant minerals are generally of acicular or rod-like habit. The grain-size is much coarser than that of the basalt (R.F. 769), but finer than that of the Bonawe granite (R.F. 827). The felspar is somewhat decomposed, and the rock has a closely-felted structure. This structure accounts for its great toughness, but the decomposed character accounts for the moderate crushing-strength (14.5 tons per square inch).

Fife “ Redstone,’’ Lucklawhill, R.F. 830.—A most interesting rock, for, although it is generally of an extremely hard and tough nature, there is found in different commercial qualities a variation of the combination of hardness and toughness (see Table IV), which is related to the formation of the crypto-crystalline ground-mass of quartz and felspar, the fine nature of which is best indicated under a high-power objective. It breaks up into angular fragments and is very abrasive in its effect on crushing machinery.

Banff Quartzite, R.F. 787.—This is a fine-grained rock with the constituent quartz grains closely morticed together.

The grain-size is somewhat irregular and the rock shows evidence of lamination in the larger crystals.

Penmaenmawr Granite, R.F. 831.—This is an augite-enstatite- granophyre, a fine-textured rock composed of augite, bastite pseudomorphs after enstatite (bastite being a term to define fibrous pseudomorphs of serpentine after orthorhombic pyroxenes), and a little hornblende in a coarse granophyric matrix of quartz and felspar. It is noteworthy for a characteristic micrographic intergrowth of quartz and felspar known as micro-pegmatite. The structure of the rock resulting from this intergrowth is in keeping with the high resistance to wear in the Deval attrition test.

Blaenau Festiniog, R.F. 694.—Is a fine-grained microgranite approaching aplite. It is composed of quartz, alkali-felspar and plagioclase, a good deal of white mica, a little chlorite and some interstitial calcite. The moderately fine grain and some interlocking of crystals suggests good mechanical properties, but the presence of chlorite and calcite in the grain-boundaries undoubtedly accounts for this rock having a lower toughness than the rocks previously discussed.

Mount Sorrel Granite, R.F. 693.—This rock, which resembles the previous in the physical tests given, is a somewhat decomposed granophyric granite of medium to fine grain. It consists of decomposed albitic felspars, chloritized biotite, and a residuum of alkali- felspar and quartz in graphic intergrowth. There is secondary epidote and much sericitic mica. Some fissuring occurs.

Aberdeen Diorite, R.F. 841.—This is a rock of high crushing-strength but not tough, and of relatively low resistance to attrition. The rock is dominantly composed of plagioclase felspars and green fibrous hornblende, tending towards actinolite. The grain-size of these minerals is coarse. There is a minor amount of orthoclase and very little quartz. The rock is noteworthy for the degree of alteration, particularly in the amphiboles, with the production of iron ore, chlorite, and epidote. The rock is strongly veined, and this feature accounts in some measure for the low values for resistance to attrition and impact. Apart from the fissures a strong rock is indicated by the fibrous constituents.

Cruachan Granite, R.F. 828.—This is a moderately coarse biotite- granite. The rock is fissured, and this fact together with the coarseness of the grain and large size of cleavable minerals, such as felspars and micas, explain the reputed poor character of the rock and the variable features encountered in the impact-tests shown in Fig. 50, Plate 1. A little micropegmatite occurs.

Warmsworth Limestone, R.F. 773.—This organic limestone is composed of the tests of organisms, both large and small, in a fine-grained muddy calcareous matrix. The grain is uneven, and the larger organisms are represented by single crystals of calcite. It is of course a soft rock as indicated by the attrition test, and has low crushing strength and impact.

Buxton Limestone, R.F. 786.—This organic limestone is very similar to R.F. 773, but more uniform in grain and finer than the former, and this factor doubtless explains the difference in mechanical properties.

Nephrite or Jade, R.F. 844.—The most characteristic features of a tough structure are exemplified by the examination of the transverse and longitudinal sections of this mineral. The section taken transversely to the direction of the fibres shows them to be exceedingly fine, even when viewed with the ¼-inch objective. In the longitudinal section also, between the darker boundaries of the fibres, this extreme fineness of thread-like grain is exhibited. The Authors have determined the Page impact of this mineral to be 40 centimetres in a direction normal to the fibre, which characterizes it as an exceedingly tough mineral. Nephrite is a compact, fine-grained tremolite (or actinolite), and is allied in composition and mineralogical characters to asbestos.

The Authors’ conclusion from the study of these rocks and their behaviour on crushing is that the abrasive value of the rock is indicated best by a consideration of the crushing-strength and impact-value. The percentage wear in the Deval attrition-test is an inverse indication of abrasiveness in the case of a rock of high crushing-strength, and of particular value where, due to excessive occurrence of cleavage- and parting-planes, the impact-value is of doubtful significance.

The design of the machine has an important influence on the amount of wear for any specific type of rock. The critical features depend upon whether the motion consists of a direct blow or nip, as distinct from a purely abrasive rubbing. That is, the provision for work-hardening of the crushing-members is an essential factor for good resistance to wear.

As regards the abrasive wear encountered, it is concluded that the nature of the action is similar to that of the grinding-wheel, that is to say, in order to grind a hard metal, it is necessary to have a tough as well as hard material, for example, the tough mineral corundum as the “ grit,” cemented into a suitable bond, the “ grade.” To grind materials of low tensile strength a material of higher intrinsic hardness, for example, silicon carbide, is required. The breaking away and exposure of new cutting-edges is necessary for efficient grinding, and this demands a “ softness ” of the bond in grinding hard materials, but a “ hardness ” in cutting soft materials in order to hold the cutting grain, which does not dull so readily. Similarly, in rock-drilling, a hard rock demands a tough tool, whereas a soft rock demands a hard tool. These facts are quite in agreement with the experience that a tough rock causes most abrasion on a hardened steel, but if the steel is soft, or work-hardening has not occurred, then a hard brittle material may be very abrasive.

In the course of the investigation, other possible factors were also studied. Thus, as regards the shape of the chippings produced, it was concluded that the natural occurrence of any planes of weakness was of dominant influence in governing shape. Apart from this, shape could be influenced by the nature and direction of the blow. From Figs. 7,11, 15, 16, 20, 22, 31, 33 and 35 showing uniformity of grading of product for widely different classes of material crushed, it is apparent that the sizing capabilities of the machines on which the tests were taken primarily govern the shape and size of the material crushed. Since the forces brought into operation must be governed mainly by the size of the material, it remains for the rock to be of influence only through, the resistance it can offer to the disintegrating force, and therefore by virtue only of its mechanical properties and frictional resistance to slipping.

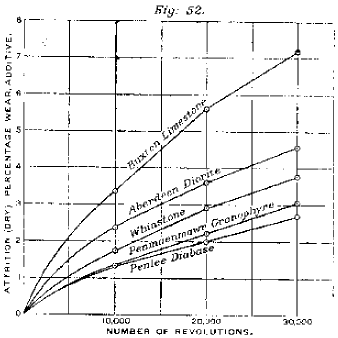

The influence of sharp edges in abrasion was studied by increasing the length of time of the Deval attrition-test, and noting any change in the rate of attrition. It would be expected that, if sharp edges are of consequence, in the tougher and harder rocks any slowing- up in the rate of attrition due to wearing down of the corners would occur later than in the softer rocks. Fig. 52, Plate 1, shows that no definite relationship of this kind is revealed in the cases studied. In order to indicate that the rock has a specific action in this test, the following experiment for improved means of testing abrasive wear under conditions encountered in crushing may be quoted.

Steel cubes of 1-inch side, accurately weighed and measured, were inserted with the rock in an extended run of the Deval machine. From time to time the cubes were removed, weighed and measured. Two types of steel, and two classes of rock, Bonawe granite, hard and tough, and Cruachan granite, fissile and weaker, were used. At the completion of the experiment after 500,000 revolutions of the machine the percentage wear was ascertained and was as given in Table IV :—

It is apparent, therefore, that a specific influence of the rock is evident, which must be more marked when the tremendous pressures used in crushing are active.

An attempt has been made to correlate the grain-size of the product of the attrition-test with the nature of the rock. In the case of the rocks Nos. 831, 824, 841 and 786, a relationship between the grain-size produced and the amount of product was obtained, but in the case of the Penlee diabase a larger grain than expected was obtained, an instance of the effect of metamorphism, and in the comparison of Bonawe and Cruachan granites there was a similar relation, but generally a smaller grain, indicating that the composition of the rock had a specific influence.

THE IMPACT TEST

In regard to the existence of veins or partings in the rock, the Authors have studied the influence of the size and direction of cutting of the test-piece on the character particularly of the impact- test. The influence of the height of the test-piece in the crushing- test has been investigated, in collaboration with Dr. Knight, in connection with two classes of granite, namely Bonawe and Cruachan (Fig. 51, Plate 1), with which he kindly supplied the Authors.

The results of a further investigation on the impact-test are shown graphically in Figs. 49 and 50, Plate 1, those in Fig. 49, Plate 1, being fine-grained rocks with the exception of Mount Sorrel granite, which could be grouped equally well with the rocks in Fig. 50, Plate 1. These rocks show that at critical lengths of test-piece a maximum is obtained in the relation of the impact and length of test-piece. With the longer test-pieces the fracture does not pass to the bottom of the cylinder, but shelves off to the side, indicating a limit to the depth of the influence of the impact. The rocks in Fig. 50, Plate 1, are all coarser-grained with the exception of the Magheramorne basalt, in regard to which the experimental data are incomplete. A maximum must be reached in the relation shown, but from the shape of the curve it is undoubtedly at a higher value of the length of the test-piece, implying a greater depth of penetration of the influence of the impact blow. A significant feature of these curves is that the rocks which show impact-values above 15 centimetres on a 1-inch standard test-piece are generally rocks of more marked abrasive nature in crushing.

A further noteworthy factor consistent with the view that high toughness is associated with an abrasive quality, and which offers an explanation of many complaints of wear in service, is the wide range of impact- and crushing-values that may be found in the same rock in different parts of a quarry. Thus in every sample of the felsite rock, R.F. 830, there is an excellent quality, but extreme toughness may be found with a diminution of direct crushing-strength in one piece of the rock, and the properties may not be equally developed in another sample of the same type of rock. Variation of rock in the same way has been indicated in the work of Messrs.

Lovegrove and Page, Nos. 282, 284, 329a and b, 230, and 231. Wide variations of impact-value are shown in the impact-values of the fissured rock Cruachan granite, R.F. 828, which are not revealed generally in most of the other rocks of a more compact nature. In regard to the direct crushing-strength these differences are not revealed (Fig. 51, Plate 1). Critical examination of the character of the curve of relationship between crushing-strength and height of test-piece on the basis of the usual Rankine-Gordon formula for crippling stress showed that the formula did not apply to the materials in question, and that a more complicated set of conditions applied to crushing rocks than to homogeneous and ductile solids such as metals.

CONCLUSION.

In these investigations the Authors have endeavoured to indicate an important aspect of the subject as applied to the design and operation of crushing-machinery. Accordingly in putting forward this information it is hoped to arouse interest and to stimulate engineers who have a wide experience in the practical conditions of crushing to contribute their views. The Authors have found that many of the complaints of wear in service in crushing-machinery are not traceable to mechanical defect or design, construction or material, but to a variable and hitherto disregarded abrasiveness of the material crushed.