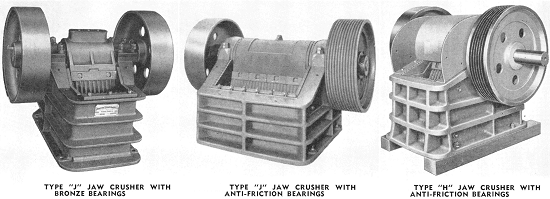

We offer two types of forced feed and yet small jaw crushers:

- The Type “H” has cast steel or alloy iron frame, steel bumper with over-size roller eccentric bearings, bronze side bearings and manganese steel jaw and cheek plates.

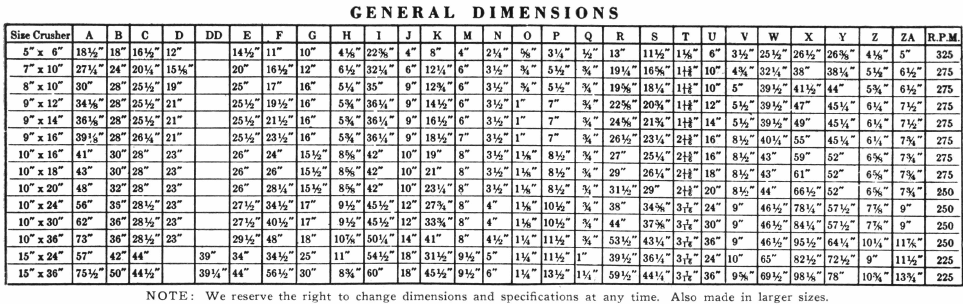

- The Type “J” is made in two styles, one with bronze bearings and the other with anti-friction bearings. Both styles have cast steel frames, steel bumpers, and manganese steel jaw and cheek plates.

Principle of Operation of our Small Jaw Crushers

Both types of Small Jaw Crushers are of the forced feed type. The main shaft is eccentric and on this eccentric shaft is mounted the movable jaw, imparting a rotary movement to the jaw. This rotary movement followed by the movable jaw actually pushes the feed down into the crusher, as well as crushing. From this action is derived the name “Forced Feed.” As a result of this action a higher ratio of reduction and larger capacity can be obtained than with the Blake type crusher.

Jaw Crusher for Small Applications

These crushers are ideal for mines where a large ratio of reduction is required. The high speeds made possible by anti-friction bearings and the high capacity and ratio of reduction due to the “forced feed” principle, produce ideal grinding circuit feeds.

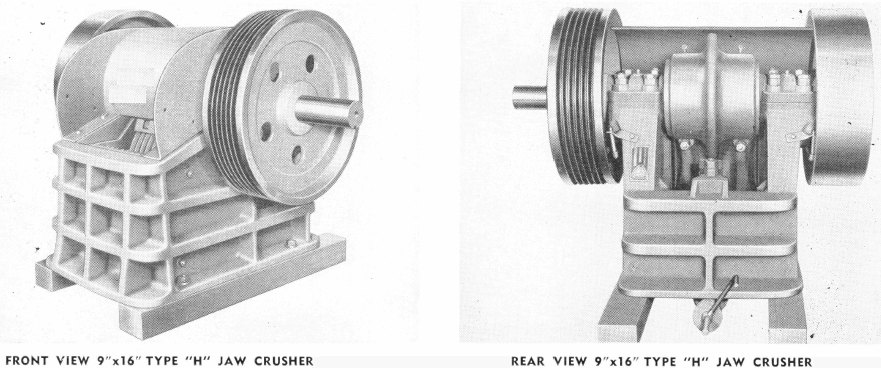

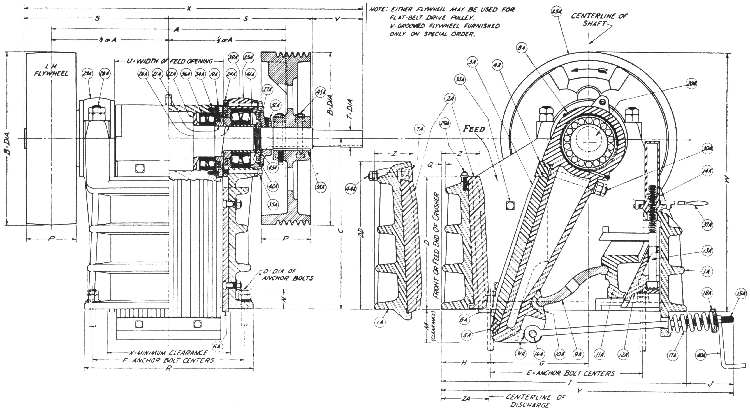

Type “H” (Type I) Jaw Crusher

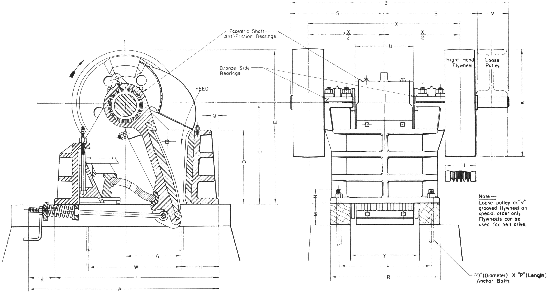

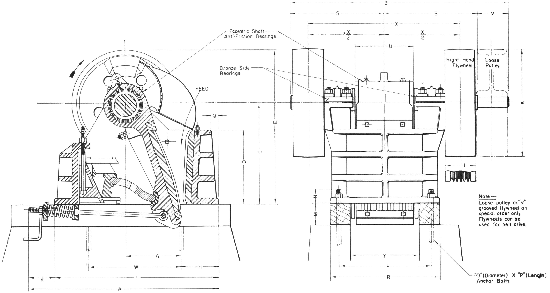

The main frame is cast in one piece except in the 5″x 6″ and 8″x 10″ sizes which are sectionalized for small muleback transportation. The frame is heavily ribbed for strength. The lower halves of the eccentric bearings are cast integral with the main frame to insure perfect alignment.

The small and ruggedly constructed swing jaw, or bumper, is mounted on heavy duty roller bearings. The entire bearing assembly is totally enclosed. Lateral thrust adjustment of each roller bearing assembly is provided.

Side bearings have heavy bronze cast inserts in both base and cap assemblies. Ring oiling is provided on the 9″x 16″ and 10″x 20″ sizes.

Standard jaw and cheek plates are of manganese steel. The jaw plates are reversible for longer life.

Cast iron toggles, designed to break when subjected to excessive stress, provide the safety factor in these units. Two different lengths of toggles are available to take care of wear on the rock crusher jaws. Adjustable toggle seat provides adjustment of jaw opening for any size product desired.

Type “J” (Types II and III) Jaw Crusher

The main frame is of cast steel, heavily ribbed for strength and rigidity with minimum weight.

Two general styles of Type “J” Crushers are available, one equipped with bronze bearings and the other with anti-friction bearings.

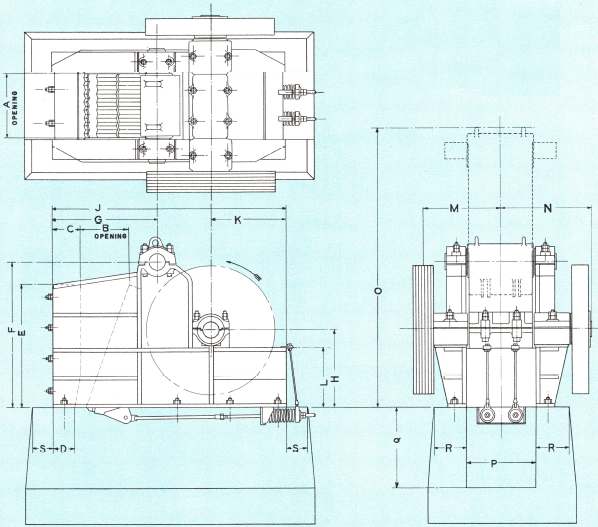

Sizes run from the 5″x 6″ to the 24″x 40″. Each size is individually designed and correctly proportioned. Bearing sizes are from two to three sizes larger than those normally used. Shaft diameters are correspondingly oversize which results in long life for both shaft and bearings.

The eccentric shaft and crusher bed are of massive construction. The crusher bed has heavy ribs properly located to give maximum strength and rigidity with minimum weight.

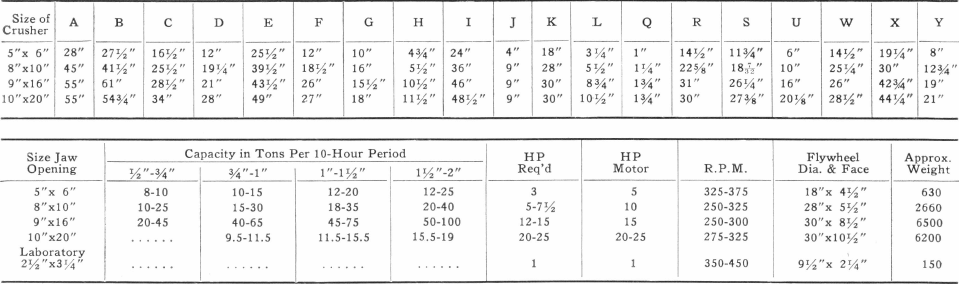

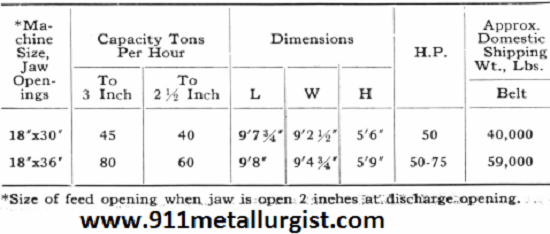

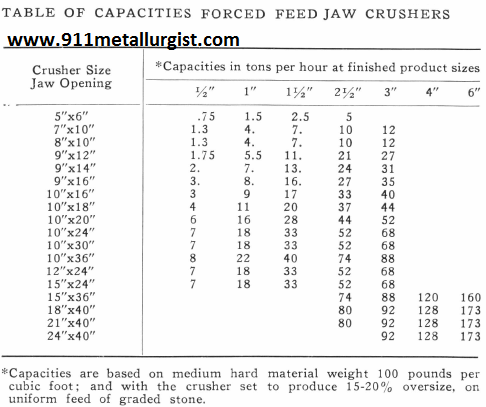

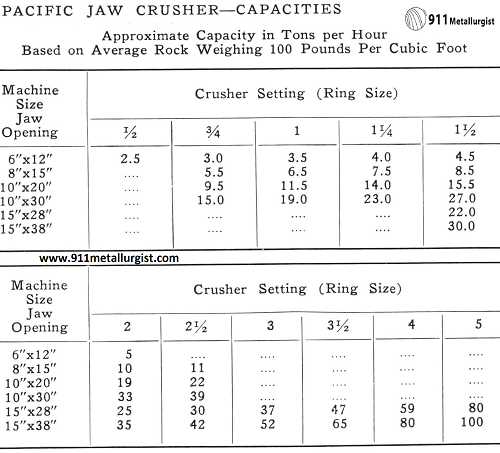

Small Jaw Crusher Capacities

Capacities in the following tables are based on material weighing 100 lbs. per cubic foot (average stone), with crusher set to produce 15-20% oversize above ring size, with uniform feeding of material, and properly sized for entering the jaw opening of the crusher. The average capacity may vary as much as 25%, depending on the character of the material being crushed.

When crushing quarry stone or similar material use straight face jaws. When crushing minus 3″ or 4″ material, especially if of abrasive nature, use curved face jaws for maximum jaw life and for more satisfactory product.

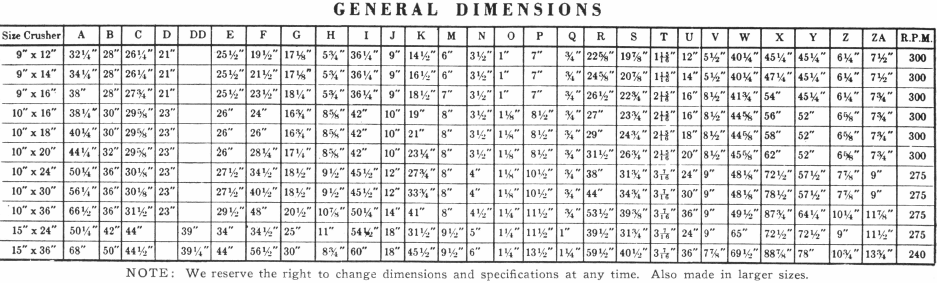

Sizing a Small Jaw Crusher (Bronze Bearings)

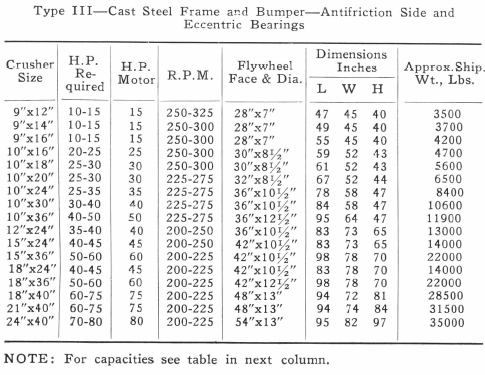

Sizing a Small Jaw Crusher (Anti-Friction Bearings)

Small Jaw Crushers (or the Blake Type) are an exceedingly strong, serviceable machine, widely used in milling operations, also for general crushing equipment and work. It is especially adapted to handling blocky ore requiring large jaw openings 3″, 4″, or 5″ in size.

The massive proportion of the frame, cast in one piece of highest quality cast iron, absorbs the severest strains incident to crushing. The babbitted bearings for the pitman shaft are cast integral with the frame and are water cooled. Swing jaw shaft bearings also cast integral with frame.

The pitman is made of cast steel and water jacketed. Under the water jacket, a cap is so arranged that a small amount of water flowing through the chamber will effectually dissipate excess heat generated by the bearing. The swing jaw is made of open hearth annealed steel and it is heavily ribbed in the back, also is provided with a recess for the toggle seat. Crusher jaws are of standard manganese steel 5″ thick and accurately ground on the back and sides. Crusher is fitted with hard iron false plates. The cheek plates are of manganese steel 1¼” thick. The two toggle plates are made of gray cast iron and fit in toggle seats made of manganese steel. The tension rod is made of forged round iron connected to the swing jaws by means of an eye bolt.

Small Jaw Crusher Capacity Table

Forced Feed Jaw Crushers

Small (Forced Feed Type) Jaw Crusher is ideal for small properties. A high ratio of reduction is obtained by the forced feed method of operation. The pitman moves on an eccentric shaft and rotates so that the material is constantly forced downward through the opening. An outstanding feature of this type of crusher, is that the jaws can be set at a certain opening and maintain this setting assuring a uniform product size. This is accomplished by the single toggle bottom pivot adjustment, which will not slip, but may be adjusted with ease when desired.

For limited tonnages these crushers will give a product fine enough for ball or rod mill feed, eliminating the need for secondary crushing. This forced feed crusher is made in three different types as described in detail in the information on each type, which follows. The capacities of all types are the same and are shown in the table on the following page.

A small Forced Feed Jaw Crusher

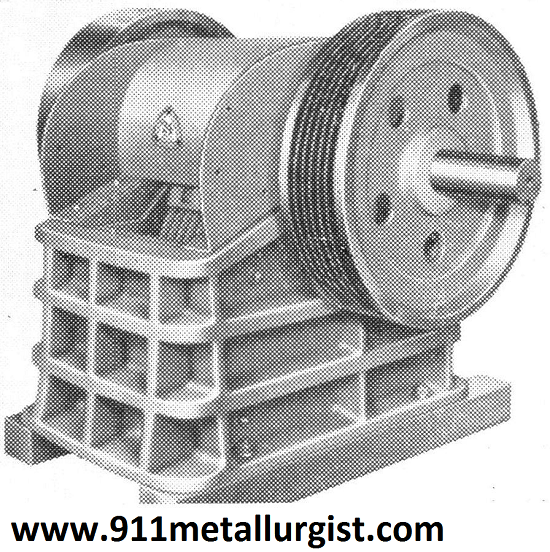

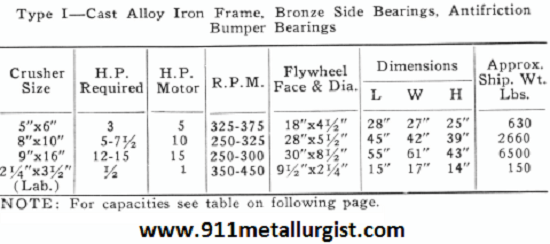

Small Jaw Crusher Design Type #1 for Sale

This small jaw crusher is ideal for small properties and is of the high capacity forced feed design. The main frame and bumper are cast of special alloy iron and the initial cost is low. The frame is ribbed both vertically and horizontally to give maximum strength with minimum weight. The bumper is ruggedly constructed to withstand tremendous shock loads. Steel bumper can be furnished if desired. The side bearings are bronze; the bumper bearings are of the antifriction type. This bearing arrangement adds both strength and ease of movement. The jaw plates and cheek plates are reversible and are of the best grade manganese steel. The jaw opening is controlled by the position of an adjustable wedge block. The crusher is usually driven by a V-to-V belt drive, but it can be arranged for either V-to-flat or flat belt drive. The 8″x 10″ size utilizes a split frame and may be packed for muleback transportation. Cast steel frames can be furnished to obtain maximum durability.

Cast Steel or Alloy Iron Frame, Bronze Side Bearings, Anti-friction Bumper Bearings

Forced Feed Jaw Crusher

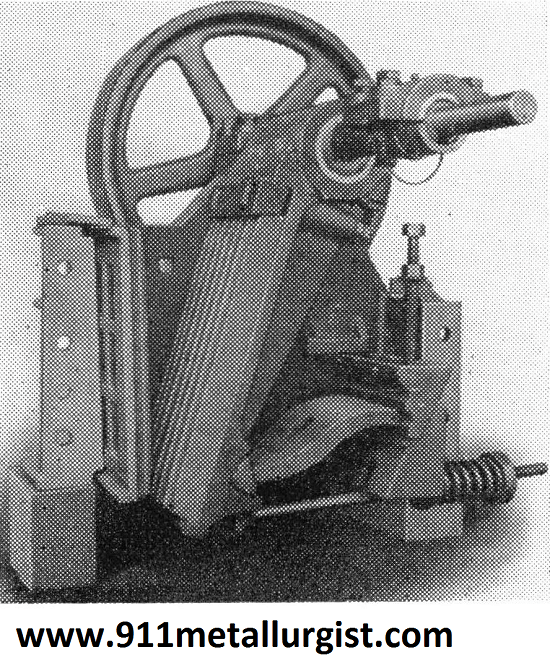

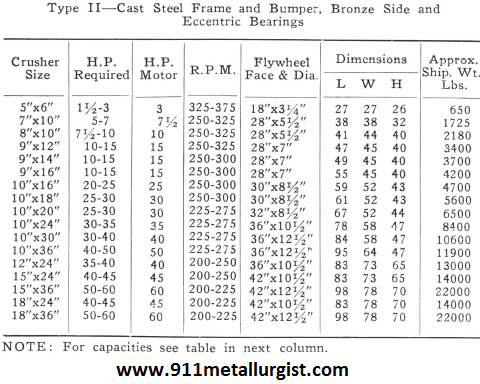

Type #2 Design Small Jaw Crusher for Sale

This type of crusher is similar in design to the Type I listed above except for having a frame and bumper made of cast steel. This steel construction makes the unit lighter per unit of size, and adds considerable strength. The bearings are all of special design; they are bronze and will stand continuous service without any danger of failure. The jaw and cheek plates are manganese steel; and are completely reversible, thus adding to their wearing life. The jaw opening is controlled by the position of an adjustable wedge block. The crushers are usually driven by V-to-V but can be arranged for V-to-flat and belt drive. The 5″x 6″ size and the 8″x 10″ size can be made with sectionalized frame for muleback transportation. This crusher is ideal for strenuous conditions.

Cast Steel Frame and Bumper, Bronze Side and Eccentric Bearings

Forced Feed Jaw Crusher

Small Jaw Crusher Design for Sale of Type #3

This type of crusher is ideal for very heavy crushing. It is similar to the Types I and II but has the additional feature of antifriction bearings. These bearings are special and are designed to take any load that can be imposed. The heavily ribbed cast steel frame makes this a unit of exceptional strength. It is ideal for hard crushing problems where continuity and ease of motion are essential. The jaw and cheek plates are manganese steel, and are easily replaceable. The unit is adjustable by means of a wedge and screw adjustment. This unit is generally arranged for V-to-V drive, but V-to-flat and belt drive are used with equal success.

Cast Steel Frame and Bumper—Anti-friction Side and Eccentric Bearings

FORCED FEED JAW CRUSHER—ROGERS

Jaw Crusher Capacity Table

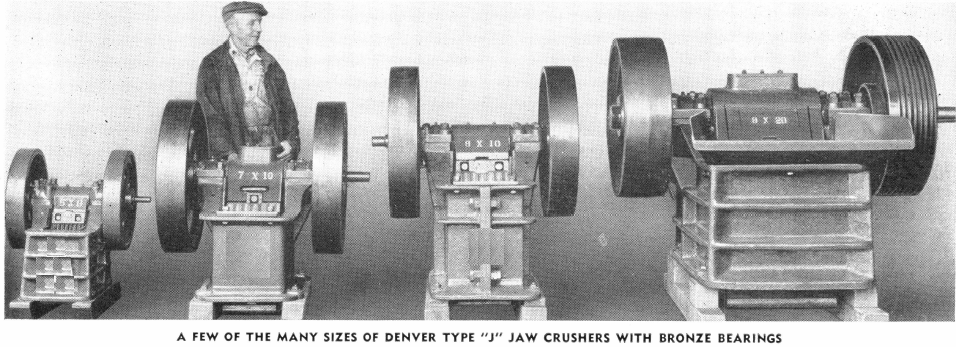

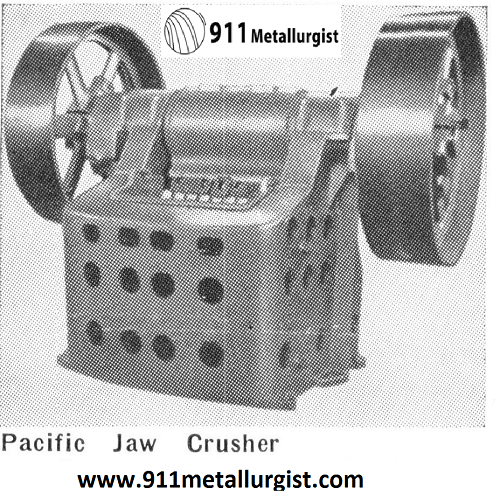

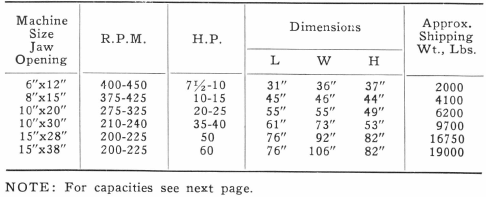

Medium Size Jaw Crushers

The design of this little crusher is based on a minimum of parts, ease of replacement of parts in the field, and interchangeability of parts. The pitman is supported at its upper end by a heavy shaft, receives its motion from an eccentric machined on the shaft and is positioned on its lower end by an inclined toggle. On the downward stroke, the top of the movable jaw moves toward the stationary jaw held in the frame. This downward action has a tendency to “force feed” the material through the jaws. On the upward stroke, the toggle moves the lower end of the pitman towards the stationary jaw on the frame, thus breaking any material in the lower finishing zone of crushing cavity. For each half revolution of the shaft there is a breaking stroke at the top and a finishing stroke at the bottom of the jaws.

The frame is constructed of a heavily-ribbed, one-piece electric steel casting, carefully heat treated. The pitman is designed as a box section and is made of steel to obtain the maximum strength with the minimum weight. Eccentric shaft is turned from alloy steel bar, accurately machined and polished. Jaw plates can be furnished either corrugated or smooth and are cast of abrasion-resistant manganese steel. Adjustment of size of product and also compensation for jaw wear may be made while the crusher is operating, by raising or lowering an adjustable wedge which closes or opens the jaw opening at the bottom. The pitman and side bearings are bronze bushed and are provided with flood system oil lubrication. Toggle is designed as a safety link which breaks should tramp iron enter the crusher. Two counter balanced flywheels are furnished with crown faces, flat faces, or with one of the two wheels grooved for V-belts as desired.

Jaw Crusher Capacity Table

Rock Crusher For Sale

Gyratory Reduction Crusher

Symons Cone Crusher

Roll Crushers

Hammermill Crushers

Source: This article is a reproduction of an excerpt of “In the Public Domain” documents held in 911Metallurgy Corp’s private library.