Gold Ore Roasting Techniques

In the case of many complex gold and silver ores roasting before cyanidation is essential if satisfactory extraction of the precious metals is to be obtained. In such cases no practical amount of grinding or prolonged contacting of the raw ore with cyanide solution will affect more than a certain low extraction; in other cases, […]

Gold Metallurgy & Leaching in Cyanicides

Cyanidation as applied to ordinary gold and silver ores is a relatively simple process. When cyanicides {cyanide-consuming elements) are encountered in small amounts in the treatment of such ores, the various schemes already discussed, such as use of a lead salt or wasting barren solution, can usually be resorted to and successful operation maintained. When, […]

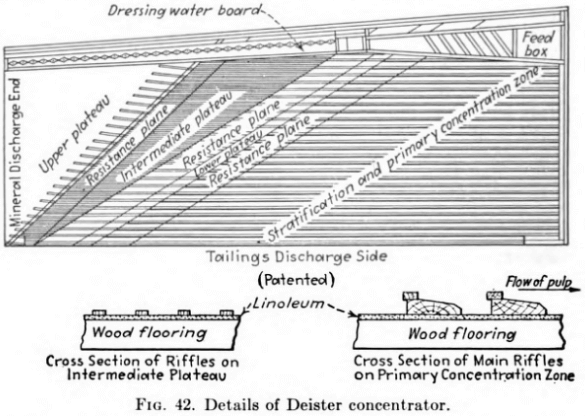

Gold Shaker Tables: Efficient Gold Recovery Solutions

Overflow from the grinding mill runs over Gold Shaker Tables which are flat and smooth and made of a fibrous wood known as “yolombo.” They are arranged in series much the same as blanket or amalgamation plate tables. The grain of the wood in the deck runs with the flow of pulp, and a sharp-pointed tool is […]

Gold Flotation

Though the gold recovery methods previously discussed usually catch the coarser particles of sulphides in the ore and thus indirectly recover some of the gold associated with these and other heavy minerals, they are not primarily designed for sulphide recovery. Where a high sulphide recovery is demanded, flotation methods are now in general use, but […]

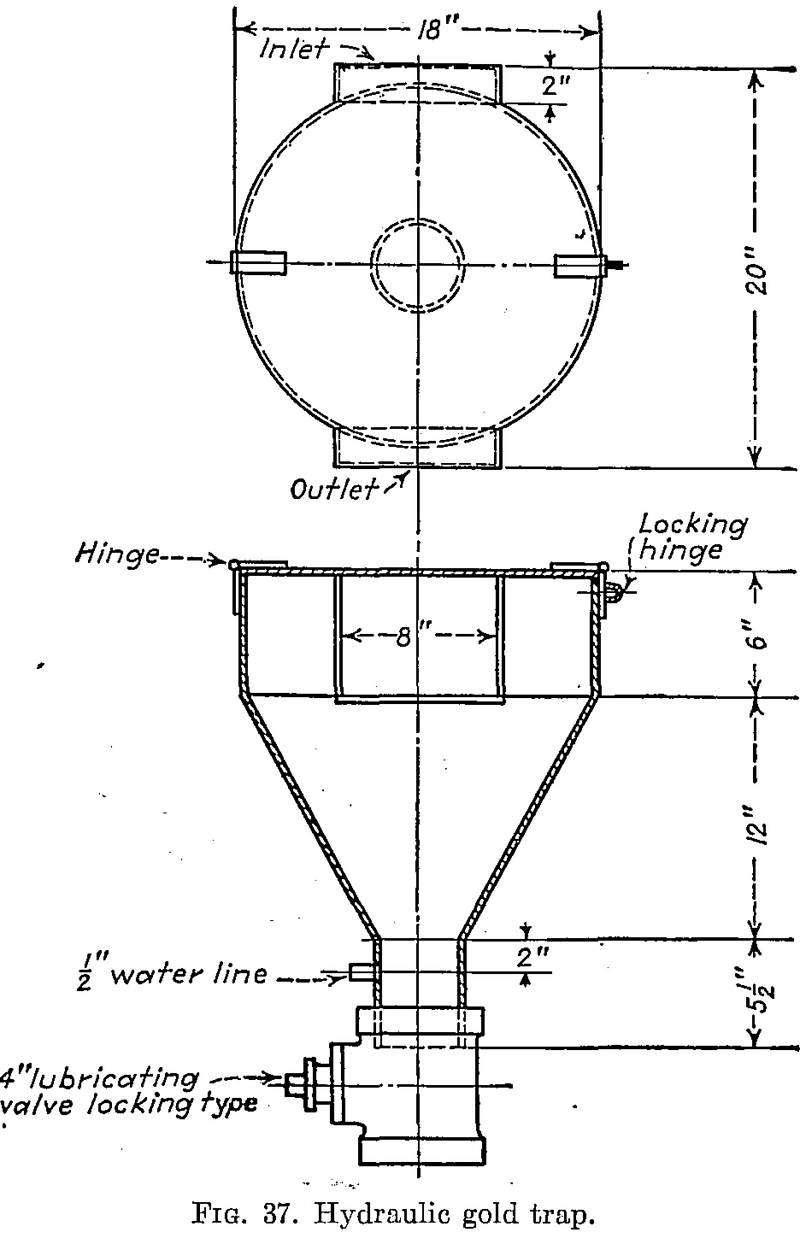

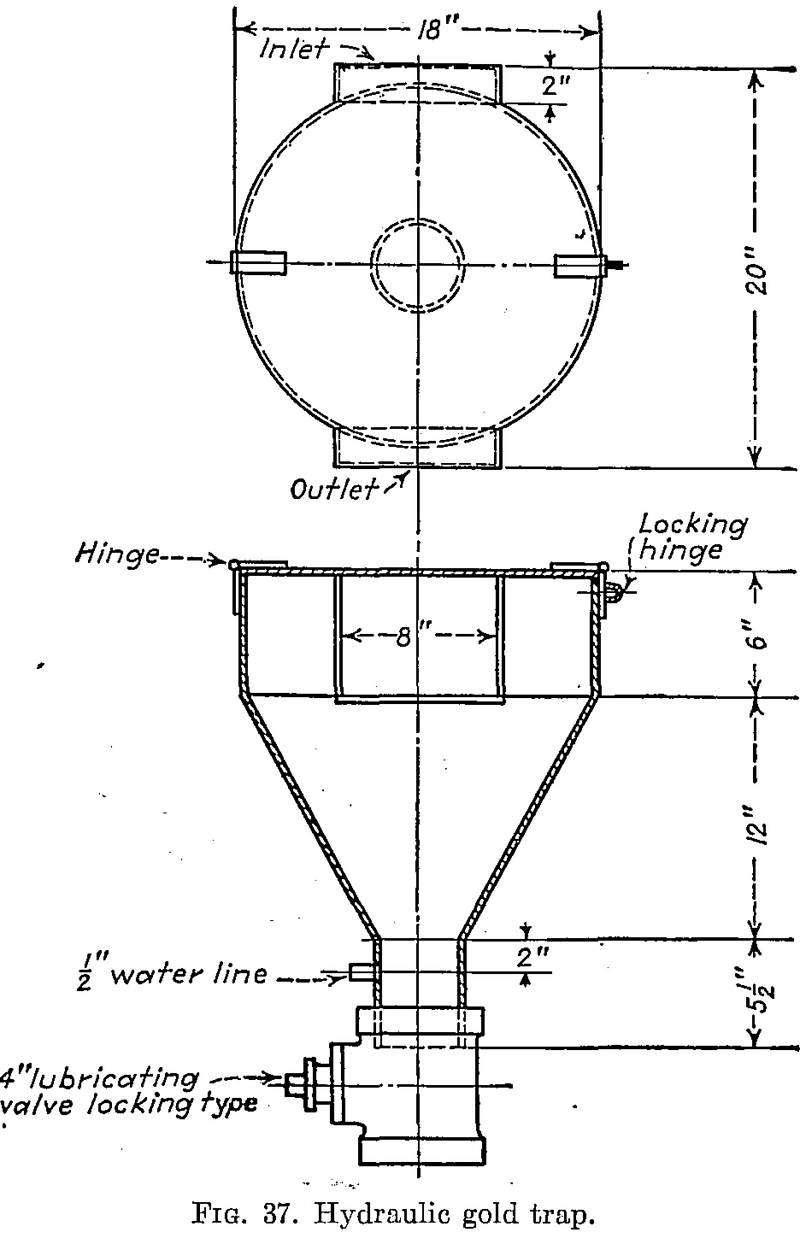

Gold Recovery Methods

Regardless of subsequent treatment, it is considered best to recover free gold as early and as completely as possible in the flow of pulp. Gravity concentration in various forms is made use of for this purpose and amalgamation used for recovering the gold from the gravity concentrate. Concentration is also extensively practised where a large […]

Counter Current Decantation Design Formula

The principle of Counter Current Decantation is simply that, when water or solution is to act upon solids, both are made to pass, in contact, in opposite directions, so that at each end the strongest or most potent portion of either is acting upon the weakest or most exhausted portion of the other. The recovery […]

Rotary Disk Filter Flappers

The concentrate is filtered on two 8 by 10 ft. Oliver filters. One of these filters is used for each roaster. The filter cake discharges onto a conveyor belt which feeds the charge directly to the roaster. The concentrate filter cake is at best a sticky, puttylike mass. If the moisture exceeds 20 per cent […]

Gold Leaching Agitation Tanks

The mixing of solids suspended in a fluid medium is still largely an art. The development of fundamental laws governing the operation is complicated by the large number of variables involved, some of which can hardly be evaluated in mathematical terms. Practical studies of the circulation patterns of the more common types of agitators are […]

Leaching Agglomerated Slimes

More recent work along these lines is reported in T.P. 790, A.I.M.E.’ by 0. C. Shephard and C. F. Skinner presented at the New York meeting in 1937, under the title of “Stabilizing Agglomerated Slimes for Gold Cyanide Leaching.” The paper describes the development of a method of stabilizing agglomerated slimes by the formation of […]

Vat Leaching of Finely Crushed Gold Ore

Vat leaching is carried out in vats ranging in capacity from 30 to 1200 tons. Sand for leaching is separated from slime in cones, V boxes, classifiers, and in collecting vats filled by distributors—the overflow in each case being slime or finer portion of the ore. As a rule, leaching is a simple process, involving […]