To present the essential points of all methods of gold refining commonly practised, as well as those of historic interest,” was the author’s purpose in this volume. The fifteen chapters of which the book consists deal with the Simpler Methods of Early Days;

- Amalgamation Process;

- Refining with Oxidising and Chloridising Agents;

- Sulphur Refining;

- Refining with Cementation Processes, and by means of Oxygen and Air;

- Miller’s Process and that adopted at the Melbourne Mint;

- Parting with Nitric Acid (two chapters);

- Recovery of Silver from Nitrate Solutions;

- Refining by Sulphuric Acid;

- Parting by Electrolysis;

- Electrolytic Refining of Gold;

- Separation of Platinum from Gold;

- Treatment of Cyanide Precipitates;

- Refining of Gold Slimes by Nitric and Sulphuric Acid; the Nitre Cake Method of Purifying Slimes.

- How Metallic Minerals Affect Silver and Gold Precipitation

Gold, as it occurs in Nature, is never pure. Occasionally the amount of alloying metal is less than 1%, hut as a general rule it is greater; the commonest alloy, in fact, the invariable one, being composed of gold and silver. Sometimes traces of copper are present, but in all other instances elements such as iron and lead appear to be present as compounds admixed with the gold. Water is invariably present, large pieces giving as much as 0.5%., while quartz and other admixtures are usually present in the cleanest specimens, and these will become at once apparent on fusing the gold in a porcelain crucible.

There is no difference in the same field between the gold to be found amongst the alluvium, or alluvial gold, and that existing in the quartz or other matrix. The gold occurring in the alluvium is not refined by any of Nature’s processes—but the accompanying minerals or metals are either oxidised or removed hence, in the recovery of gold from reefs impurities are often collected and introduced, thus making it of lower value than the corresponding alluvial gold, and also giving rise to erroneous and widespread statements to the contrary.

- Experimental Work

- Refining with Sodium Bisulphate

- Refining with Sulphate of Silver and Salt

- Refining with Boric and Phosphoric Acid

- Phosphoric Acid and Oxidising Agents

- Boric Acid and Oxidising Agents

- Phosphoric Acid and Oxidising Agents

- Refining with Potassium Chlorate

- Refining with Sulphur and other Metals Together

- Refining with Sulphur and Sodium

- Refining using Sulphide of Antimony

- Refining of Gold with the Cementation Processes.

- Older Processes with Nitre.

- Older Processes with Common Salt.

- Refining Gold Bullion with of Oxygen or Air.

- Dr. T.’ Kirk Rose’s Experiments with Oxygen and Air.

- Work Done in Western Australia.

- Miller’s Process of Gold Refining.

- Equipment and Supplies

- Parting gold with Nitric Acid—Experimental Work.

- Cupellation

- Gold Parting with Silver as the Alloying Metal.

- Gold Parting with Zinc as the Alloying Metal.

- Gold Parting with Sodium as the Alloying Metal.

- Parting Gold with Nitric Acid on a Large Scale.

- Silver-Gold Alloys.

- Zinc-Silver-Gold Alloys Obtained in the Cyanide Process.

- Recovery of Silver from Nitrate Solutions.

- The Precipitation of Chloride of Silver.

- The reduction of Chloride.

- Gold Refining using Sulphuric Acid.

- Experimental Work on Gold-Silver Alloys.

- Experimental Work on Gold-Zinc Alloys.

- Experimental Work on Gold-Zinc-Silver Alloys.

- Experimental Work on Gold-Silver-Tellurium Alloys.

- Parting with Sulphuric Acid Commercially.

- The Gutzkow Process.

- The Process as Carried on in Australia.

- Parting Gold by Electrolysis—

- Mobius’ Process.

- Description of the Plant.

- The Improved Process.

- Electrolytic Refining of Gold.

- The Separation of Platinum from Gold.

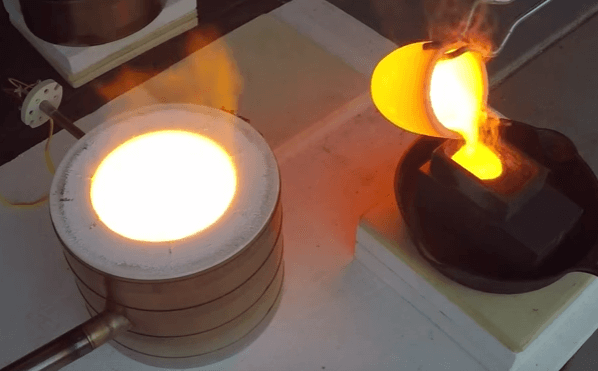

- Using a Muffle Furnace

- The Treatment of Cyanide Precipitates.

- Gold Precipitated on Zinc.

- The Clean-up of Zinc Slimes.

- Smelting the Precipitate Direct.

- Treatment with Sulphuric Acid.

- Effect of Sand, Lead, and Other Impurities.

- Removal of Lime and Lime Salts.

- Experiments with Caustic Soda.

- The Distillation Process.

- Other Methods of Refining Gold Slimes—

- Treatment with Strong Nitric Acid.

- Treatment with Strong Sulphuric Acid.

- The Removal of Copper with Sulphuric Acid and Air. Dissolving Out Gold with Chlorine.

- The Nitre Cake Method of Purifying Slimes.

- Experiments to Prevent Dusting.

- The Manufacture of Nitre Cake.

- The Direct Use of Nitre Cake.

- Effect of Temperature.

- Time Required.

- Vessel Required.

- Effect of Various Impurities.

- Dry Method of Refining Slimes.

- Caldecott’s process.

- Taverner’s Process.

- Merril’s Process.

- Slimes from Electro-refining of Copper.

- Separation of Gold and Platinum.

- The Refining of Base Bullion.

- Gold Ore Chlorination in Laboratory Tests

- Gold Chlorination & Gold Bromination = F(Silver)

- Precious Metals Refining Practice

Alluvial gold in Australasia is, practically speaking, an alloy of gold and silver. In no place is its composition constant over any wide area, and perhaps the only general statements which can be made are that when it occurs in igneous rocks the percentage of silver is higher than in the sedimentary strata. In one shoot, or that portion of a reef which carries gold contents without any break, the ratio of gold to silver, so far as the writer’s experience goes, is constant.

Another shoot in the same reef may give slightly different values, but on the whole will approach the first, yet only a few feet away may occur a parallel reef with an altogether different ratio. To discover the natural solvents which carried gold and silver, and from which they were deposited in this constant alloy, would be to have at our disposal probably a new and effective method of gold refining base alloys.

Source: Gold Refining by Clark, Donald