Sulphide ore of lead and zinc containing considerable silver was submitted for testing with the purpose of determining a flowsheet for the production of separate lead and zinc concentrates for marketing at their respective smelters. It is necessary to recover as much silver as possible in the lead concentrate as a higher return for this silver is realized than for the silver in the zinc concentrate. The ore contained sphalerite, a portion of which was easily floatable but difficult to depress in the lead flotation circuit.

Also, the recovery of silver minerals occurring in a lead, zinc sulfide ore is efficiently accomplished using Flowsheet #2. The process consists of selective flotation to produce a mixed silver, lead concentrate for maximum smelter return and a separate zinc concentrate. Over-grinding of silver minerals is detrimental to efficient flotation recovery, so the Flash Flotation Unit-Cell is used in the grinding circuit to recover a large part of the silver and lead values as soon as liberated. The flowsheet is for a plant having a capacity in the range of 300 to 500-tons per day.

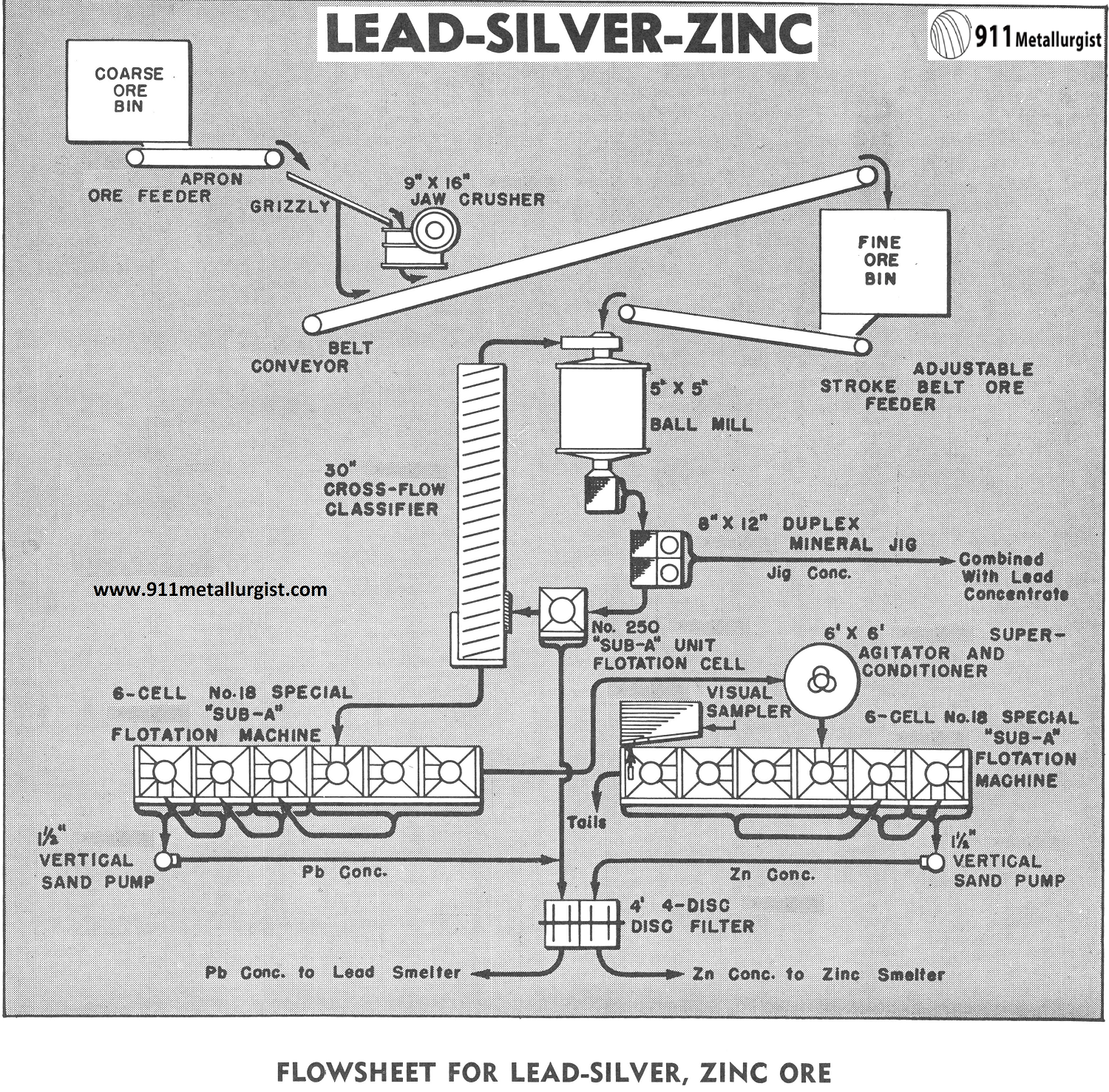

A Pb-Ag-Zn Separation Circuit Flowsheet #1

Crushing Section

The crushing section of this 50-65 ton mill consists of a conventional layout of single stage crushing. The mine ore is fed from the coarse ore bin to a 9″x 16″ Forced Feed Jaw Crusher by means of a Apron Ore Feeder. The crushed ore is conveyed by a Belt Conveyor to the Bolted Steel Fine Ore Bin. A Adjustable Stroke Unit Flotation Cell are incorporated in the Belt Ore Feeder delivers the fine ore to the ball mill.

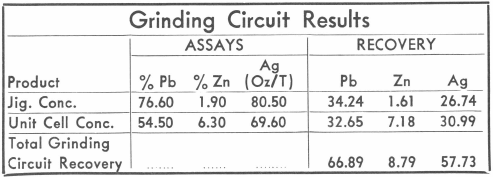

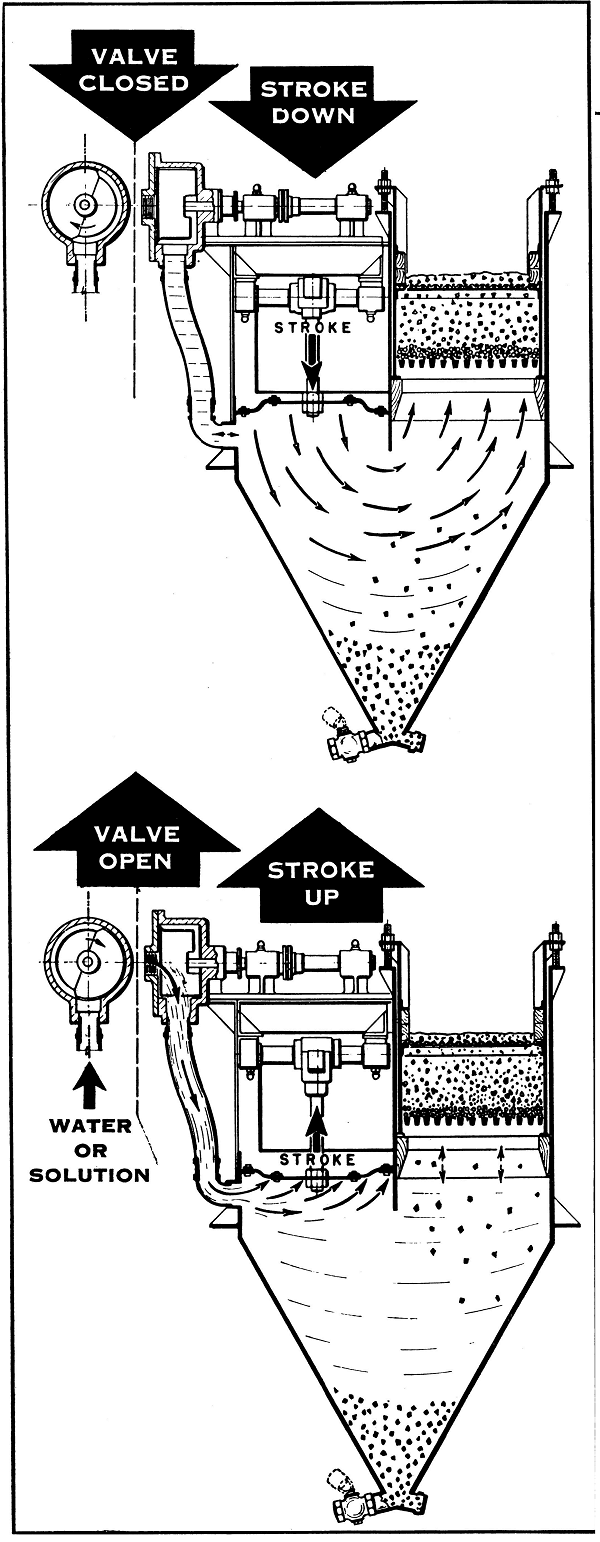

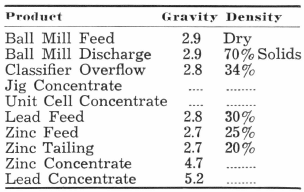

Grinding Section

The Mineral Jig and the grinding circuit for immediate recovery of a substantial amount of the lead and silver at a relatively coarse grind. The 5′ x 5′ Steel Head Ball Mill discharges into an 8″x 12″ Selective Mineral Jig which in turn discharges into a small flash Flotation Cell. The tailings from the Unit Cell flow by gravity to the 30″ Cross-Flow Classifier. The Mineral Jig and the flash cell treating an unclassified feed, produce high-grade concentrates of lead and silver with a minimum amount of zinc. Recovery of these important amounts of lead and silver at this point not only prevents detrimental sliming of the lead mineral and possible subsequent loss, but also increases the amount of new feed that can be fed to the ball mill. By taking advantage of recovering a clean product representing a high recovery of the lead leaves only a small amount of the lead to be recovered in the selective flotation section.

Selective Flotation Section

This section of the flowsheet uses two 6-cell (32 x 32) Flotation Machines. The classifier overflow is fed by gravity to the first rougher cell of the lead machine. Three rougher cells provide ample contact time for the flotation of the lead. This rougher lead flotation concentrate is then delivered by gravity to the cleaner cells. Three cleaner cells are used for triple cleaning of the lead concentrate. This triple cleaning was recommended because of the easily floatable zinc that could not be effectively depressed by conventional zinc depressant reagents. Roughing, plus triple cleaning in a 6-cell machine with no pumps or elevators is an example of “flexibility” a distinctive feature of “Sub-A” Flotation Machines.

The lead circuit tailing is then conditioned with reagents in a 6′ x 6′ Super-Agitator and Conditioner prior to zinc flotation. The conditioned pulp is then floated in a 6-cell No. 18 Special “Sub-A” Flotation Machine for the production of a cleaned zinc concentrate. This machine is arranged for four rougher cells and two cleanings of the rougher zinc concentrate.

A Selective Mineral Jig and a “Sub-A” Unit Flotation Cell operating in a ball mill-classifier circuit.

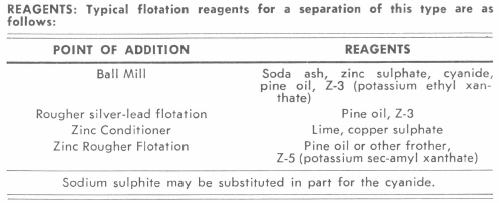

Pb and Zn Flotation Reagents

Soda ash and zinc sulphate are fed to the ball mill by means of Cone Type Dry Reagent Feeders. Cyanide, sodium sulphite, MIBC frother and xanthate (Z-3) are fed to the grinding circuit and lead flotation circuit using a multi-compartment Wet Reagent Feeder. Lime and copper sulphate (CuSO4) are added to the zinc conditioner and pine oil and xanthate (Z-5) are stage added to the zinc rougher circuit using Wet Reagent Feeders.

Visual Sampling

The Visual Sampler, consisting of a ¾” Suction Pressure Diaphragm Pump and a No. 13A Wilfley Concentrating Table, takes a portion of the final zinc tailing. This unit enables the operator to determine visually the results of flotation. Any necessary change of reagents is immediately indicated by observation of the concentrate streak shown on the table. Many installations of the Visual Sampler have proved this unit to be a money-saving necessity in any flotation plant.

Pb and Zn Concentrate Filtration

Thickening, prior to filtration, was not recommended in this case because of the rapidity at which these concentrates filtered and the relatively small tonnage of this mill. Thickening is advisable on slower filtering ores and on larger tonnages.

The final lead-silver concentrates (including the Flash Flotation Cell concentrate) are filtered on the 4″4-disc Filter, the filter cake discharging directly into concentrate bins. The dewatered Mineral Jig concentrate is combined with the filtered lead concentrate in the storage bin.

SUMMARY of How to Separate Pb, Silver and Zinc Sulphides #1

The above flowsheet incorporates the first rule of milling procedure—recover the mineral as soon as freed—this is accomplished by the Jig and Flash Unit Cell in the grinding circuit. Note that a high-grade lead product representing 2/3 of the total lead (very low in zinc), is recovered in the grinding circuit. This flowsheet successfully answers The Problem by recovering 84% of the total silver in the lead concentrate.

Silver, Lead & Zinc Flotation Circuit #2

The recovery of silver minerals occurring in a lead-zinc sulfide ore is efficiently accomplished using the above flowsheet. The process consists of selective flotation to produce a mixed silver-lead concentrate for maximum smelter return and a separate zinc concentrate. Over-grinding of silver minerals is detrimental to efficient flotation recovery, so the Flash Flotation Unit-Cell is used in the grinding circuit to recover a large part of the silver and lead values as soon as liberated. The flowsheet is for a plant having a capacity in the range of 300 to 500-tons per day.

CRUSHING SECTION

The crushing section consists of primary and secondary crushing with intermediate screening. Both crushers are located in the same building and conveniently attended by one operator. A minimum of conveying equipment is required by this arrangement. Dust collecting facilities are, likewise, limited to only one building.

GRINDING CIRCUIT

The crushed ore after automatic sampling is subjected to two-stage grinding using a Rod Mill in open circuit and a Ball Mill in closed circuit with a Classifier. The Unit Flotation Cell receives the discharge from the ball mill for recovery of a substantial amount of the granular silver minerals together with galena as soon as freed. Reagents are added to the ball mill. Tramp iron and occasional oversize gangue are removed from the circuit by the Spiral Screen attached to the ball mill and this prevents excessive wear or plugging of the unit cell. The classifier is of the latest design.

The Mineral Jig is not included in the flowsheet, but on many ores of this type it is applicable either alone or with the unit cell. The grade of jig concentrate is usually very high grade and ideal for blending with the flotation concentrate. If native silver or gold values are present, the jig is a very essential addition to the flowsheet and would be used on the rod mill discharge in this case.

SELECTIVE FLOTATION of Silver Lead Zinc Sulfides

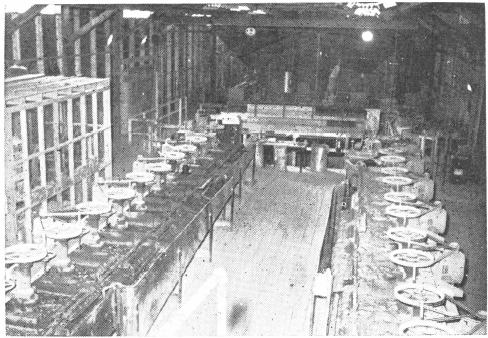

The classifier overflow is treated in a conventional manner using “Sub-A” Flotation Machines of cell-to-cell design which enables double cleaning of the silver-lead and zinc concentrates without the need of pumps. For large tonnage operations the “Sub – A” Free Flow Machine is optional for roughing and scavenging, but the cell to cell type is always used in the cleaner circuits where high selectivity is essential. The two flotation banks are arranged so that the banks face one another and can be conveniently controlled by one operator from a single aisle. Operation of the Conditioner can also be observed from this aisle. A Sampler is used on the zinc tailing to provide an instant means for the operator to evaluate plant results. Some plants find it beneficial to use a visual sampler on the lead tailing ahead of the zinc circuit. The Sampler is also useful for evaluating the lead or zinc concentrate. General view of the flotation section at a modern silver-lead-zinc mill. The lead circuit is on the left and the zinc circuit is on the right.

THICKENING AND FILTERING

The silver-lead concentrate (including the unit cell concentrate) and the zinc concentrate are separately treated through wet cyclones to remove the coarse sulfides as thick underflow products suitable for direct filtration. The cyclone overflow products are ideally suited for thickening and subsequent filtration with their respective cyclone underflows. This procedure avoids any overload of heavy sulfides in the thickeners and, therefore, simplifies the operation of the thickeners. SRL Pumps are engineered for use with wet cyclones and give trouble-free service.

SAMPLING

In addition to the feed sample, which is cut by means of a Type “C” Automatic Sampler, the final silver-lead and zinc flotation concentrates are sampled using Type “B” cutters. The final plant tailing is also sampled in the same manner.

SUMMARY

This flow-sheet incorporates all features of a modern day mill for optimum efficiency and general simplicity for ease of operations. Instrumentation devices can be included to facilitate automatic control of the plant circuits if desired.

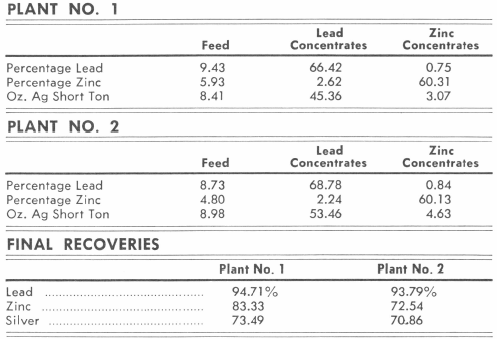

Typical Metallurgical Results

Many factors affect the metallurgical results of every plant. However, in a study of this type it is interesting to note the recoveries and grades that are actually being made at successful mills. The figures of these two plants are included for their value in making economic studies of new deposits.

Source: This article is a reproduction of an excerpt of “In the Public Domain” documents held in 911Metallurgy Corp’s private library.