Table of Contents

Rock fragmentation by explosives is presently the most inexpensive process available to the hardrock mining industry. The challenge remains, however, to control the explosive energy to optimize fragmentation produced by blasting and minimize the deleterious effects associated with the use of explosives. These harmful effects are often simply stated as damage, which regroups damage to the rockmass, damage to the mine workings and structural damage. These effects can also be summarized as the additional costs associated to explosives. Controlled blasting aims to minimize these costs by deliberately modifying drilling and blasting procedures.

Blast Damage

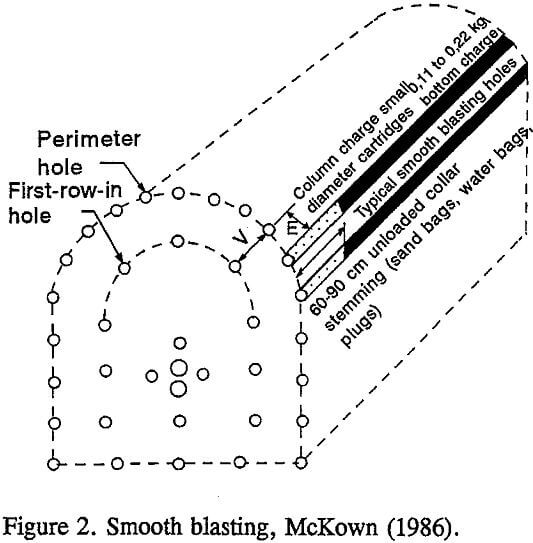

Controlled blasting will attempt to modify the type of explosives, or the placement of particular explosives, such that the damage zone created by the perimeter holes does not exceed the damage zone produced by the holes within the perimeter, or vice-versa. A rockmass can be considered damaged when it no longer reacts elastically but deformation is plastic. This corresponds to the zone where the strain level has exceeded the strength of the rock or, Holmberg et al (1984):

ε = σ/E =v/c………………………………………………………………………………(1)

Where ε is the strain, σ the stress, E is the Young’s modulus of elasticity of the rock, v is the vibration velocity and c is the wave propagation velocity.

Propagation of Vibrations

In an isotropic material, particle velocity should be proportional to the explosive charge and inversely proportional to the distance, or:

PPV = kWα/Rβ…………………………………………………………………(2)

Where PPV denotes the peak particle velocity, mm/s, W is the charge weight, kg, and R is the distance, m. The constants k, α and β depend on the structural and elastic properties of the rock mass and vary for each particular blasting site. The charge weight should consider the Relative Weight Strength (RWS) of the explosive.

Controlled Blasting Techniques

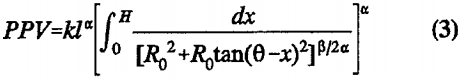

The five main controlled blasting or perimeter control techniques are line drilling, pre-splitting, cushion blasting, fracture control blasting and smooth blasting.

These holes usually have a tighter spacing than production holes, are lightly loaded and are fired simultaneously before the production holes. The objective is to create a crack between the adjacent perimeter holes to limit the propagation of radial cracks from within the excavation. The preferential orientation of the crack propagation is enhanced by the simultaneous firing of the holes.

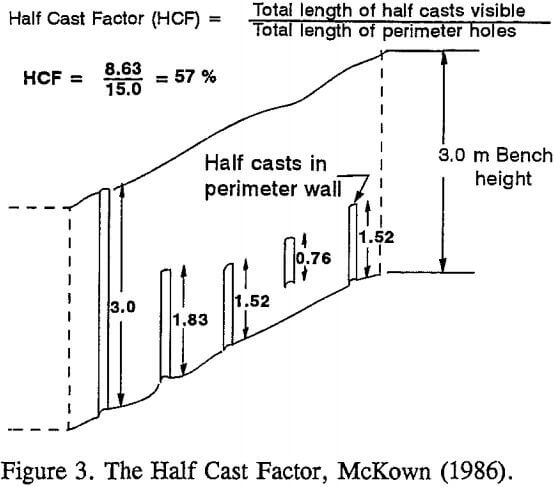

Another method of assessing the relative performance of controlled blasting techniques is the computation of Half Cast Factors (HCF). Controlled blasting will leave part of the perimeter drillholes intact, these ‘half-casts’ or ‘half-holes’ are usually referred to as half-barrels. In theory, the more controlled the blast is, the more one should see half-barrels along the perimeter of the excavation.

Controlled Blasting Design

The main criterion for explosives selection is borehole pressure produced by the explosive charge, which affects the strain induced in the rock. A practical method of characterizing the various types of explosives which can be used is in terms of a linear charge per metre, ANFO equivalent.

l = 90d²…………………………………………………………………………(4)

Where l is the linear charge concentration in kg ANFO-equivalent per metre of borehole and d is the hole diameter in metres. Given the hole size and the linear charge weight, the predicted damage zone for each explosive can be assessed.

Controlled Blasting Experiments

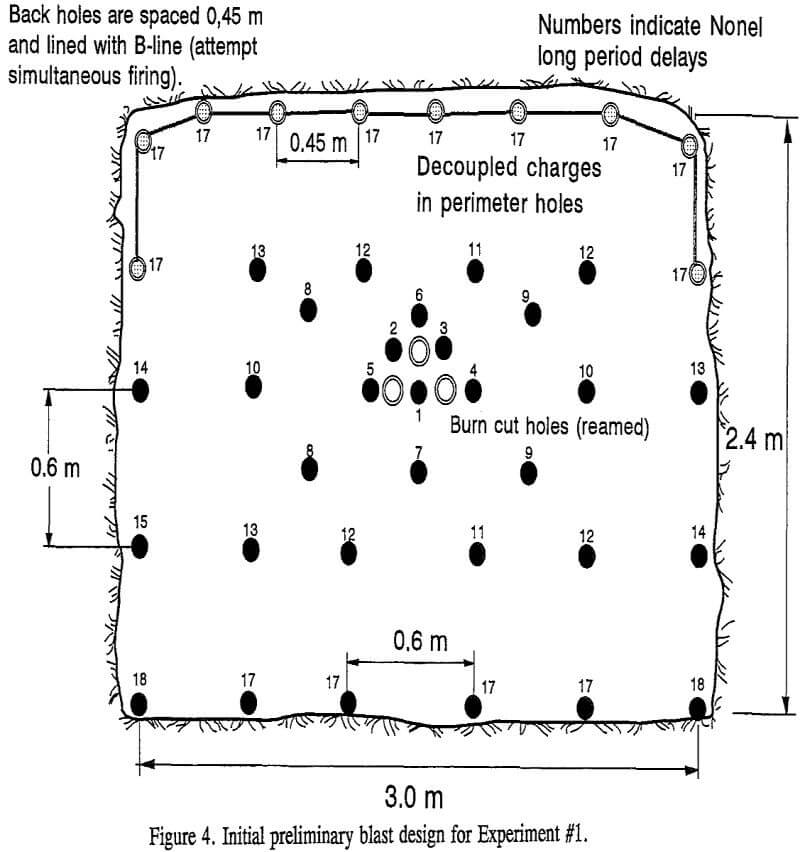

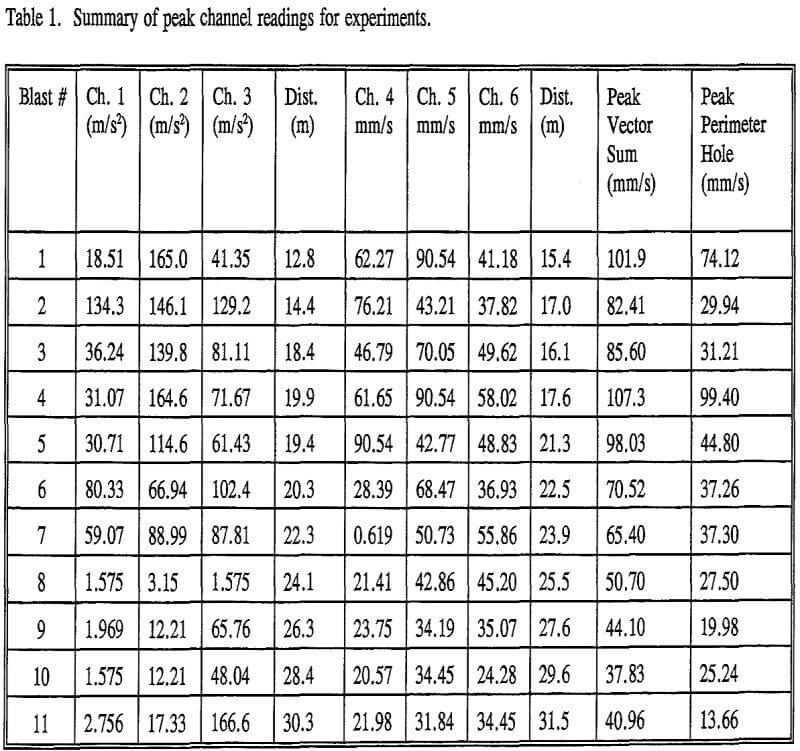

Eleven controlled blasting experiments were conducted on the 70 m level of the Experimental Mine. Most of the experiments consisted in testing variations of smooth blasting techniques, one pre-split blast (Experiment 4) and one blast round with short delay detonators (Experiment 5).

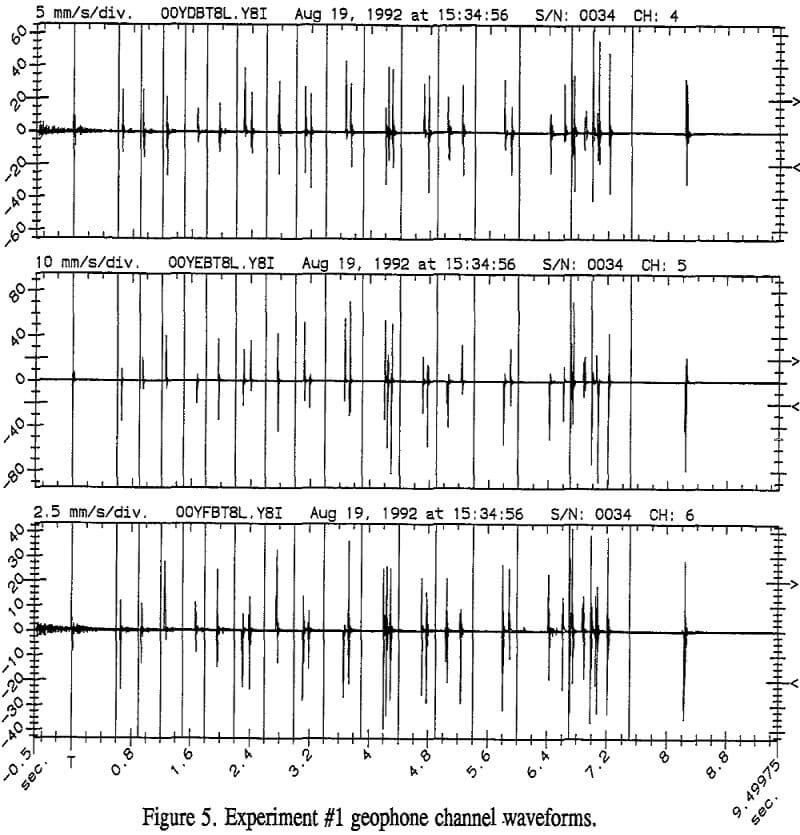

All of the blasts were monitored with the Instantel Omniprobe 1200, to which were attached sets of orthogonal high-frequency geophones and accelerometers. ANFO was used as the main explosive and 19 mm diameter semigelatin dynamite charges were used in the perimeter holes at the back. Conventional pyrotechnic detonators were used. The number of loaded holes varied from 36 to 43 in the experiments.

Analysis of Results

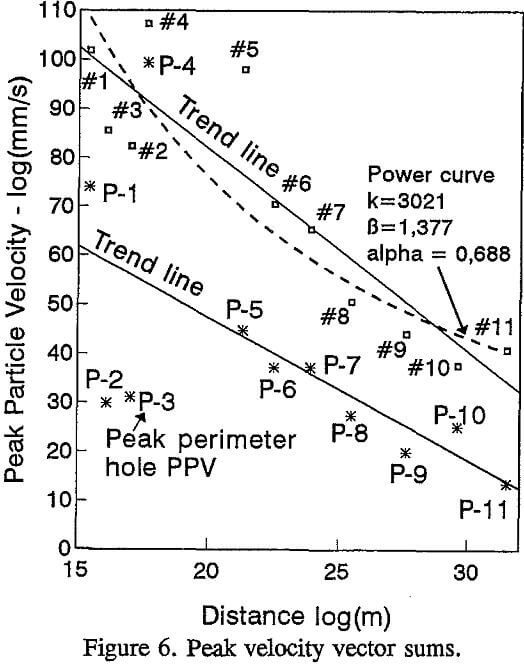

Assuming that the waveforms can be attributed to individual detonations, parameter β of equation (2) can be determined by statistical fit with a power curve. The explosive charge per hole is 1.89 kg ANFO equivalent. With this value, β is 1.377 with a regression coefficient of 0.906. With the power curve and given that peak values are all determined for one quantity of explosives, k and α cannot be determined directly.

Assuming that the waveforms can be attributed to individual detonations, parameter β of equation (2) can be determined by statistical fit with a power curve. The explosive charge per hole is 1.89 kg ANFO equivalent. With this value, β is 1.377 with a regression coefficient of 0.906. With the power curve and given that peak values are all determined for one quantity of explosives, k and α cannot be determined directly.

Experiments 5, 6, 7 and 10 produced PPVs above the trend line. In the case of Experiment 5 the PPV value is probably due to the superposition of waveforms caused by the use of short period detonators. Experiments 6 and 7 required re-blasting of bootlegs; the relatively high PPVs can be attributed to higher confinement in these cases because of the lookout angles of the perimeter holes in relation to the breast holes.

Explosives Malfunctions

The controlled blasting study was hampered by problems which occurred in the burn cuts for several of the experiments. Explosives malfunctions, namely sympathetic detonation, partial and full desensitization were seen both from the waveform recordings and examining the face after the blast. These malfunctions, often considered to be caused by the detonators or the explosives, are more likely caused by the spacing of the holes in the cut or the rockmass characteristics.