Table of Contents

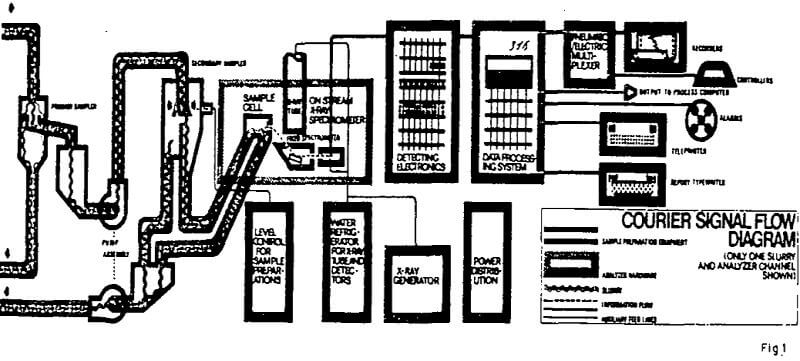

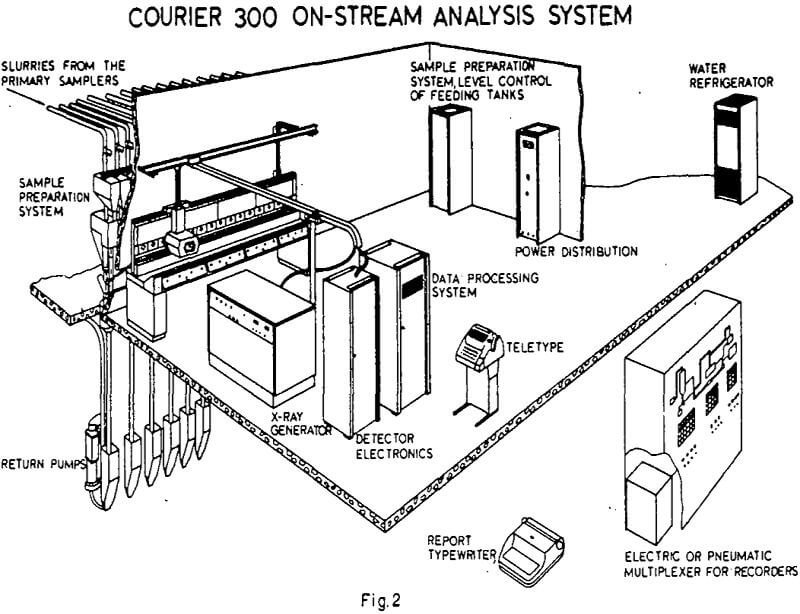

The Outokumpu Company’s Courier 300 System is a complete package that can be installed and handed over with the key. It includes the equipment needed for sampling and handling the slurries. It has been developed from the start to meet industrial demands. Obviously an on-line system must comply with far stricter standards than one designed for a laboratory. Assays are computed by an Outokumpu 316 digital data processor, which is an integral part of the system and controls its entire performance.

Courier 300 sampling system

The Courier 300 sampling system has been developed for the past three years in co-operation between the Pyhasalmi, Keretti and Vihanti Concentration Plants and the Research Laboratory of the Outokumpu Company. The following requirements were imposed:

- The sample had to be representative.

- The system’s components had to be the simplest, safest and most abrasion and corrosion-resistant available.

- The system had to be suitable for a wide variety of concentrators.

- The system had to be available in 1 – 14 sample circuit units depending on the clients’ wishes.

- The price had to be reasonable.

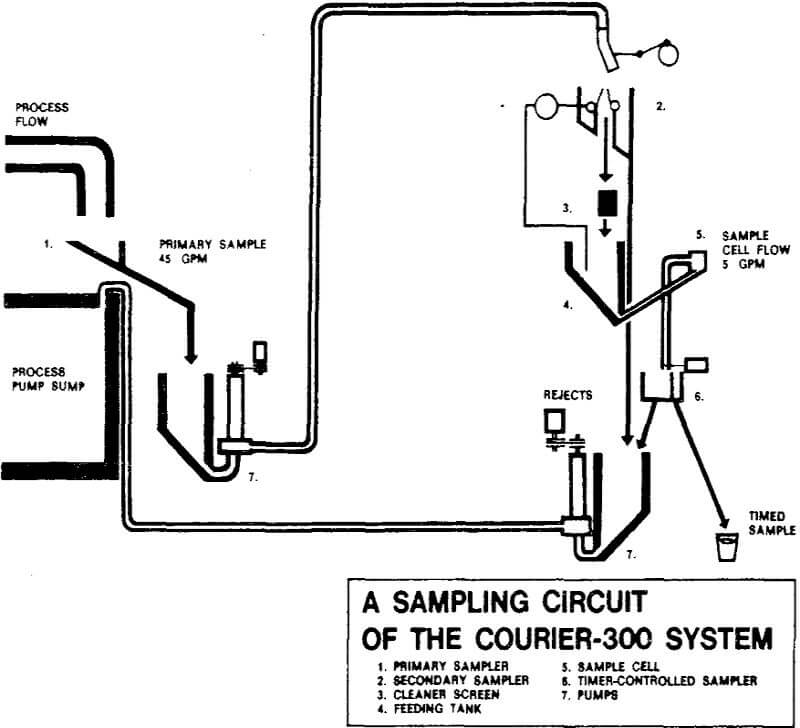

The sampling system consists of up to fourteen sampling circuits. Each circuit comprises of the following components,

- Primary sampler

- Secondary sampler

- Secondary sampler screen

- Feeding tank

- Sample cell

- Timer-controlled sampler

- Pumps, sumps and pipes

A primary sample of about 45 gallons per minute is cut from a vertical process flow. The sampler is a continuously operating model developed by the company. Its cutter moves to and fro along a 70° sector around a vertical shaft. The cutter has an opening which is controlled by the slurry level in the sump of the primary pump. The jaws of the opening are moved by a compressed-air membrane motor.

The flow through the sample cell of the analyser is about 5 GPM. The final sample is cut from the primary sample flow. The operation of the secondary sampler is continuous. The end of the primary sample pipeline is a rubber tube that swings to and fro over the cutter of the secondary sampler. The jaws of the cutter are controlled by the slurry level in the feeding tank.

The timer-controlled sampler takes samples for shift and 24-hour analyses. The timed samples are taken from the sample-cell return flow. The end of the sample-cell return flow tube is moved by a timer – controlled piston. Each sample contains about 1/8 gallon.

On-stream X-ray spectrometer

The X-ray data for assaying comes from a layer of slurry a few hundredths of an inch thick nearest to the sample-cell window. For obvious reasons, this layer must be exactly representative of the process flow. In developing the flow cell for the Courier analyser, therefore, we made an extensive study of the flow hydraulics of the slurry. The sample cell meets the severest criteria.

Strictly representative samples are obtained over a wide range of pulp densities, flow speeds and particle – size distributions.

The measuring head moves to and fro along the row of the vertical sample tells, which number 14 at the most. Experience has shown that, to keep the sample strictly representative and ensure reliable on-line operation, each slurry must have its own flow circuit and the sample cells should be stationary.

The head includes fixed channels for fluorescence radiation of each of the elements analysed, plus one or two channels for scattered radiation, depending on the application. The maximum number of channels is eight.

The spectrometers are fitted with high-resolution bent and curved crystals. The signal-to-background ratio of the quartz crystals used is such that in normal working conditions the total background of the e. g. copper channel corresponds to about 0.03% copper, when measuring copper tailings.

The number of adjustments to be made in the Courier System has been minimized. This not only applies to the electronics, where the only items to be adjusted are the voltage of the detectors and the discriminator window (which are normally checked two times a year). No adjustments are needed for the spectrometer, either.

Assay computation

As stated earlier, the basic requirement for reliable analysis is strict representativeness of the sample at the point where it is excitated by X-rays. The design of the spectrometer with solidly fixed high-re solution crystals and stabilized detectors results in excellent measurement sensitivity and high precision in the acquisition of data for the analysis. The digital electronic system also ensures that there is no inaccuracy in processing the data.

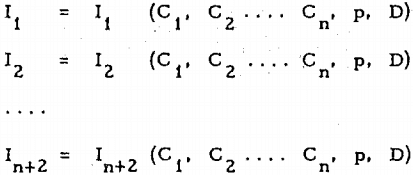

The following description of the method of assay computation gives an idea of our technique. The physical model is a group of non-linear equations derived on a purely theoretical basis. An equation has been derived for each type of the spectrometer channels. Each of the equations determines the theoretical intensity of a given spectrometer channel as a function of the major slurry variables: the concentrations of elements, composition of minerals, percentage of solids, and particle size. The coefficients in the equations of the model are in principle universal, such as absorption coefficients but in practice, it is better to use experimental values because of non-homogenities in the particles, inadequate data on compositions, etc. The group of equations in the physical model can be written as follows:

where I1 n+2 are the theoretical intensities, C1 n, the percentage concentrations of the elements, p the percentage of solids in the slurry and D the average particle size. The number of equations is the same as the number of spectrometer channels.

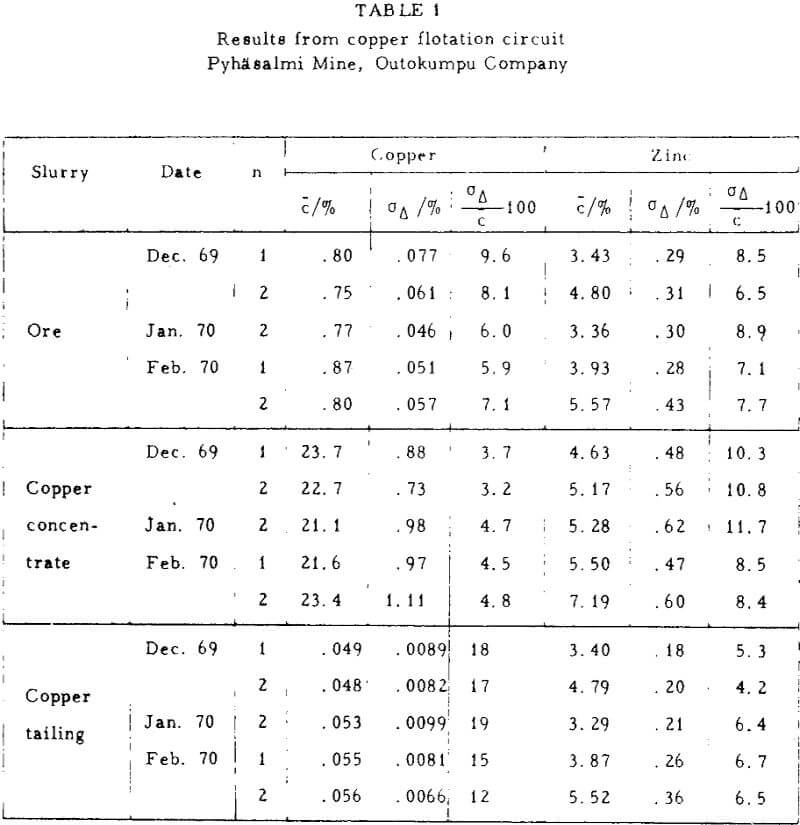

Most of the data on the accuracy of the Courier at the Pyhasalmi copper and zinc mine were obtained at the beginning of 1970. Samples were taken daily from three slurries – ore, copper tailings and copper concentrate – in order to chcck the performance of the analyser. Special care was taken to synchronize the measurement and sampling and assure the representativeness of the sample. To avoid unnecessary work only copper and zinc were analysed chemically because the iron assayed by the Courier was of minor importance in this flotation circuit.