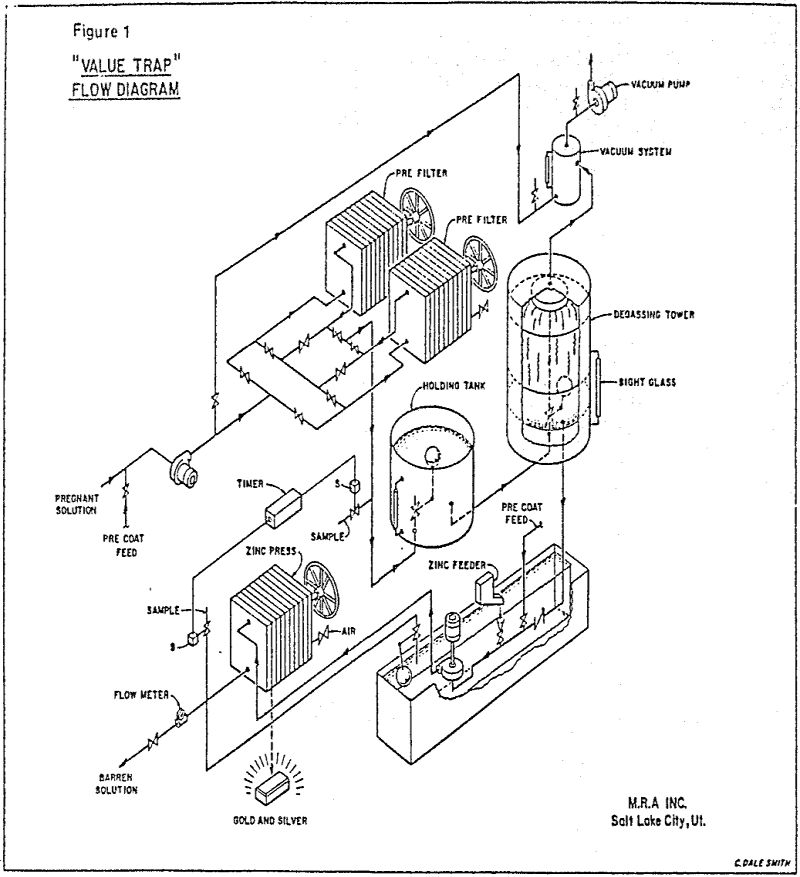

The removal of metal values from cyanide solutions, fortunately, can be done in several ways. The oldest practiced method is, cementation with zinc, or Merrill-Crowe.

Clarifying Filters

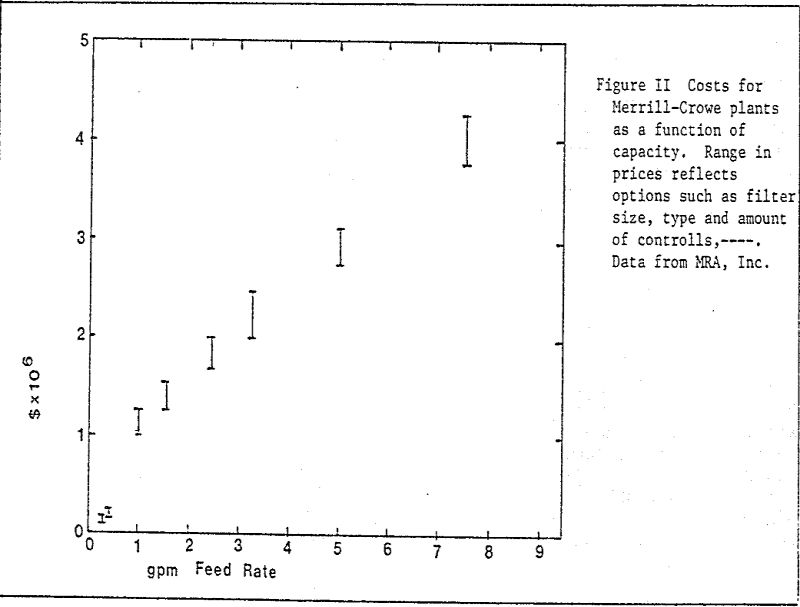

Today the clarifying filtration is done with every kind of filter imaginable. Most of these filters are precoated with diatomaceous earth, DE, to produce extremely clear solutions. The design criterion of these filter vary with turbidity of the leach solutions. As a rule of thumb, one should have at least 2.2×10³ m³/s (1.5 foot squared per gpm) of pregnant feed. Normally there are two prefilters arranged such that production does not stop during clean up and precoating of the pre filters.

Vacuum degassing is done in a packed tower. The clarified pregnant solution is introduced into the top of the tower and percolated down through the packing.

Zinc Dust Addition

Zinc feeders are the nemesis of the Merrill-Crowe operators. The angle or repose of zinc dust is in excess of 90 degrees, it will “rat hole” and bridge. The cures for this problem are legion! In small package units the feeders are tapered bottomed boxes with augers or springs to advance the zinc to a discharge port. The rate of discharge is adjusted by varying the speed of the auger. To keep the zinc flowing the entire feeder is vibrated and/or finger springs are set to “click” along the auger.

The equation for cementation is:

NaAu(CN)2 + 2NaCN + Zn° + H2O = 2NaZn(CN)4 + Au° + ½H2 + NaOH

It is apparent that one mole of zinc will precipitate one mole of gold ( or silver or copper ). Therefore, one gm of zinc should precipitate 3.02 gm of gold or 1.64 gm of silver or 0.97 gm of copper.

Filtration of Product

A word of warning is in order about product filter feed punps. These pumps MUST have submerged seals. There is a tendency to try to cut costs by not not placing this pump under barren solution. This is especially true with small “shoe string” operations and in some snail packaged units. The problem surfaces when the seals start to leak, and they will leak. Because the seals are at the center of the pump, they are in a negative pressure area and air leaks into the pump. A small air leak can quickly undo everything accomplished in the vacuum tower.

I have seen an operation when everything was functioning under acceptable limits using a packaged unit that did not have submerged seals. During clean up, the precipitate was gray ( vrs. the normal black ). The seal in the product pump was leaking, providing oxygen to the system which placed all of the zinc into solution and left nothing but the DE precoat in the filter.

Clean Up and Melting

It is general practice to wash the precipitate with sulfuric acid to remove excess zinc, copper, lead. This wash should not be done with hydrochloric acid. Despite the the low solubility of silver chloride, large quantities of silver can be taken into solution in strong chloride environments, especially in the presence of zinc, as AgCl2-.

The goal in melting into dore is to produce 90+% gold plus silver content, to reduce refining charges at the refining houses.