Table of Contents

- Acknowledgments

- Chemical Treatment

- Advantages and Disadvantages of Chemical Treatment

- Gravitational Methods

- Background

- Conventional Thickeners

- High-Rate Thickeners

- Advantages and Disadvantages of Conventional, and High-Rate Thickeners

- Multiple-Plate Thickeners

- Types of Multiple-Plate Thickeners

- Advantages and Disadvantages of Multiple-Plate Thickeners

- Sizing Thickeners

- Centrifugal Sedimentation

- Background

- Solid-Bowl Centrifuges

- Screen-Bowl Centrifuges

- Disk Centrifuges

- Advantages and Disadvantages of Centrifuges

- Sizing Centrifuges

- Sigma Concept

- Pilot-Plant Testing

- Filtration Equipment

- Background

The disposal of wet fine-grained wastes from a milling operation can be a difficult challenge for the plant operator. He or she must consider the stability of the material after deposition, environmental consequences, and, above all, economic constraints. Waste material or tailings with a minimum of material smaller than 200 mesh (0.0029 in) can be piled up or used as backfill with few complications because it drains water easily and is relatively stable.

On the other hand, materials with a high percentage of particles smaller than 200 mesh present far more problems for water drainage and stability. The small size allows intermolecular attraction between water molecules and solid particles to influence the hydraulic and structural characteristics of the material. As a result, when these fine tailings are saturated, they have low permeabilities and have little or no shear strength.

Current tailings disposal practice is to mix these fine tailings or slimes with large volumes of water and to pipe the resulting slurry to settling ponds. In these ponds, the solid particles settle out of the slurry and the remaining liquid is decanted out of the pond. This disposal method works well; however, it requires large ponds. Also, as a consequence of the small particle size, these slimes may not become completely settled for years and may present a possibility of structural failure.

These problems can be mitigated or eliminated if the water content is substantially reduced prior to disposal. Many different methods have been developed for separating small-sized solids from liquids. A cursory evaluation of these methods was done by the Bureau of Mines. This report presents the results of the study in a format that should assist mill operators who must establish a tailings disposal system or upgrade an existing dewatering circuit for metal or nonmetal mining operations; dewatering coal slimes is reviewed in a report done under contract to the Bureau of mines. Many of the conclusions in this report are based on experience from the coal processing, power generation, and sewage treatment industries in the hope that a sharing of knowledge will be beneficial to those interested in dewatering slimes.

The descriptions of each dewatering method, along with the lists of manufacturers and equipment in appendixes B and C, should assist mill operators in making decisions about the most appropriate and economic methods of tailings dewatering to investigate further.

Acknowledgments

The author thanks Ken Miyoshi, mill superintendent, Western Nuclear Corp., Wellpinit, WA, for reviewing this paper and offering considerable technical advice.

Chemical Treatment

This paper discusses the physical methods of separating solids and liquids. It must be acknowledged, however, that any discussion of solid-liquid separation must include some comments on chemical additives used in this process. Other Bureau projects are investigating the various aspects of chemical additives, so only a brief review of these substances is included in this report.

Chemical treatment is often the first step in slurry concentration. Chemical additives (or reagents) are added to a slurry to promote formation of more easily separated solid masses. For many of the dewatering devices evaluated in this report, chemical pretreatment is frequently used or may even be necessary to remove as much water from the solids as possible prior to mechanical dewatering.

For many years, glue, gums, starch, lime, and similar additives were used as flocculating aids to improve the separation rate of small solids from liquids. These substances were reasonably successful but increased the volume of the solids that had to be transported and disposed after dewatering.

With the introduction of polymers or polyelectrolytes, great improvements occurred. Settling rates for solids increased by a factor of 10, 20, or more, and solids that could not previously be thickened were responsive to the addition of polymers. In addition, lower doses of these additives were needed to produce the desired thickening. As a result, the volume of the solids did not increase and production rates improved.

Advantages and Disadvantages of Chemical Treatment

The proper application of chemical additives will—

- Increase separation efficiency.

- Increase throughput.

- Require a minimum investment for mixing equipment.

There are, however, several disadvantages to using chemical additives—

- They can be very expensive.

- A large concentration of some additives may be needed to produce the required results.

- Not all slurries are responsive to the chemical additives.

Chemical additives are often needed to increase the efficiency or throughput of a dewatering system. The use of chemical additives must be carefully considered because they are expensive to purchase and will increase the processing cost.

Gravitational Methods

Background

This section describes equipment known as thickeners because of their capability to concentrate or thicken the solids from a slurry that has a very low solids content. In gravitational methods, the force of gravity causes the solids to settle and separate from the liquid. In the mining industry, flocculants are added to the slurry which cause the solids to form larger masses or “flocs” that settle at an accelerated rate. With respect to dewatering slimes, thickening equipment is often used to concentrate the fine particles for further processing by other dewatering equipment which will then produce the final dewatered product.

Over the years, nomenclature has been adopted that is specific to thickener functions in the mineral processing industries. The solid-liquid mixture that is to be separated by sedimentation is known as the feed. The sedimented material having a solids content higher than that of the feed is the underflow. The clarified liquid from which solids have been removed is the overflow. This terminology is used even for equipment where the overflow does not migrate over a weir or the underflow does not emerge from the bottom of the sedimentation device.

Regardless of name or variation in design, all gravitational equipment depends on sedimentation to produce the thickened product. During initial sedimentation, solid particles in a nonturbulent solution move downward under the influence of gravity relative to the liquid. The velocity of this movement increases until the upward force of drag, caused by the viscosity of the liquid, equals the downward force of gravity on the particles. These particles then fall at a constant velocity, called the terminal or free-settling velocity. In addition to gravity, the size of the reacting force is dependent on the particle diameter and density and the solution density and viscosity. The magnitude of the terminal settling velocity can be shown as

Vs = Gx²(Ds-Dl)/J8µ…………………………………………………..(1)

where Vs = the terminal settling velocity, feet per second,

G = the gravitational constant, feet per second per second,

x = the particle diameter, inch,

Ds = the particle density, slugs per cubic foot,

Dl = the liquid density at a specified temperature, slugs per cubic foot,

µ = the viscosity of the liquid at a specified temperature, pound-seconds per square foot,

and J = a correction factor for particle shape, dimensionless.

Where nonspherical particles are concerned, vs alters by factor (J), which is less than 1.0. Where there is a low density of particles, vs also decreases by a factor that is a function of the particle concentration. The purely mathematical description of sedimentation is imprecise owing to variations in particle diameter, shape, and distribution for any given slurry. Therefore, the above formula will be used for the determination of boundary conditions such as the smallest particle size just completely retained by a given device.

As sedimentation continues, the concentration of the solids increases through the process of “hindered settling” and then continues into the “compression phase.” In this phase, a further concentration of the sediment occurs and an increase in the concentration of solids takes place; however, the process proceeds at a slower rate. This slowing down is due to the fact that during the exchange of solid matter for water, the water does not reach the top relatively unhindered but has to pass through increasingly narrowing capillaries between the more densely packed particles. Also, the friction between the touching particles slows down the compression process.

As the sedimentation process reaches equilibrium in the tank, four zones will be present (fig. 1):

- Clear solution zone.

- Feed zone.

- Transition zone.

- Compression zone.

The clear solution zone contains the clarified solution of the overflow. The feed zone has the solids concentration of the unsedimented feed. The transition zone has a higher concentration of solids in hindered settling. The compression

zone has the highest concentration of solids in compression and is the origin of the underflow.

Gravity thickeners consist of open tanks with a feed inlet at the top and a means of collecting the sludge at the bottom by a rake. As the contents are slowly stirred by the rake rotation, the solids settle and are drawn off the bottom in a continuous underflow. Gases escape from the surface, and clear solution is removed by the overflow weir. Chemicals are added to the feed to aid settling, and, in the mining industry, many gravitational thickeners produce underflows having over 40 pct solids with recoveries approaching 100 pct.

Three general types of thickeners will be discussed in this report: conventional, high-rate, and multiple-plate thickeners. The following sections discuss each of these in detail.

Conventional Thickeners

Conventional thickeners use the sedimentation principle for liquid-solid separation. They are much larger than high- rate or multiple-plate thickeners and have several characteristic design features such as—

- Cylindroconical shape.

- Annular overflow weir.

- Walkway and feed pipe support

- Feed well.

- Drive mechanism and rake.

- Underflow cone or trench

Conventional devices are typified by a cylindrical upper portion attached to a shallow conical section having the apex oriented downward (fig. 2). The width or diameter of these thickeners is much larger than the depth. Most conventional thickeners are equipped with an annular overflow weir, which may be located internal or external to the tank and which

is equipped with a froth baffle. Usually, overflow is regulated through a notched weir so that adjustments can be made to compensate for uneven tank settlement in the subjacent soil. Most thickeners have a walkway to the center of the thickener. The walkway usually serves as support for the piping that carries the feed to the center of the machine. The feed pipe terminates at a device located at the center of the thickener, which is called the feed well or center well. The function of the feed well is to dissipate the kinetic energy of the incoming feed and to form a zone of quiescence conducive to sedimentation. Feed wells are manufactured in many shapes and sizes because recent information shows that the feed introduction method and the feed well shape greatly affect sedimentation behavior. The function of the rakes in a thickener is to gently move the sedimented solids from the periphery towards the center discharge point. The movement of the rakes is provided by a drive mechanism. After the sedimented solids have been moved toward the center of the tank by the rake, they are removed from the thickener through a cone or trench located near the bottom center.

Although they are all based on the same sedimentation process, a variety of conventional thickeners are being manufactured which differ from each other in their design. For instance, the feed pipe support may extend from the edge of the tank to the center or may span completely across the diameter of the tank. The rake arms in some thickeners are rigidly attached to a central vertical shaft or lattice, while in other designs, the arms may be suspended from cables. Drive mechanisms also vary from worm-spur gear combinations to hydraulically operated push-pull arrangements for rotating the rake arms about the central axis. Each of these thickener configurations is designed to assist the process of continuous sedimentation by steadily removing the consolidated solids and the clear liquid to make room for the introduction of more feed material.

High-Rate Thickeners

Recently, several manufacturers have introduced high-capacity or high-rate thickeners, which have much smaller tanks than conventional thickeners. The lateral area for a conventional installation ranges from 5 to 10 ft² for each ton of solids thickened per day, but the area of high-rate units may be as low as 0.3 to 0.6 ft² for each ton of solids per day.

These high-capacity thickeners have smaller tanks because they discharge the feed directly into the bed of settled solids and use chemical additives to hasten the flocculation of the sediments. The efficiency of the flocculation depends on how thoroughly the flocculant and the slurry are mixed. The many different high-capacity thickeners on the market use various mechanisms or designs to mix the flocculant with the slurry.

High-rate thickeners, while smaller than conventional models, can often meet or exceed the performance of the larger units. In one such comparison between a conventional and a high-rate thickener, the latter unit produced underflow solids concentrations equal to or greater than those produced by the conventional unit. This was done even at feed input rates 10 times that of the conventional thickener. These results, though, were dependent on the slurry solids being responsive to the chemical flocculant used during the trials.

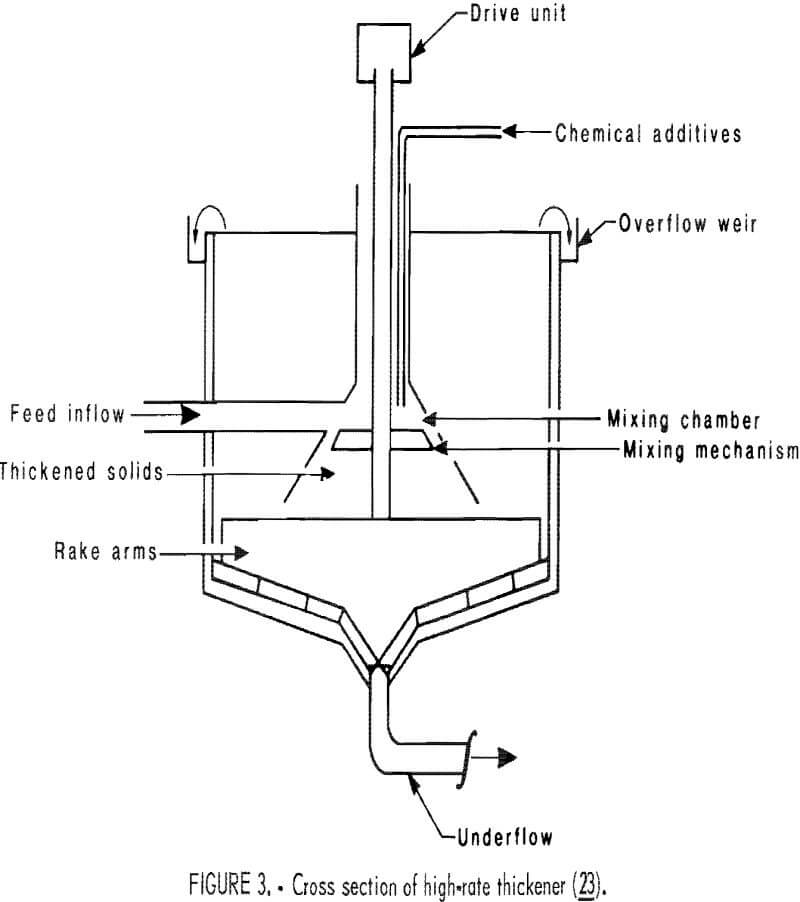

Figure 3 shows a typical high-capacity thickener. The chemical additives are combined with the incoming feed and previously thickened solids in the mixing chamber. This mixture is thoroughly churned by the blades of the mixing mechanism. The high concentration of the solids causes all chemical reactions to occur quickly and completely so that flocculation is considerably improved. This mixture moves from the reaction chamber to the clarified zone, where the flocculated solids quickly settle, to be used again with the incoming feed. A portion of the solids is collected inward by the rakes and evacuated as underflow. As in conventional thickeners, the clear solution migrates upward through the circulating sludge bed and exits over the overflow weir.

Gravity plays only a part in the solids-liquid separation in this thickener. It would be more precise to refer to this as a filtration unit in which the filter media is a suspended sludge bed. This is true because as the solids settle, the pore spaces between them become more restricted and trap other solids being carried along with the water migrating upward.

The horsepower required to operate these thickeners is approximately equivalent to the horsepower for conventional units having a similar capacity. The drive unit employed by high-rate thickeners is usually a hydraulic arrangement.

Advantages and Disadvantages of Conventional, and High-Rate Thickeners

Thickeners have been used extensively by the minerals industry for concentrating slurries, and over the years many design improvements have been made that enable them, to be very reliable and efficient for thickening operations. Gravitational thickeners, in general, may be advantageous to an operation because they—

- Are capable of continuous operation.

- Are capable of processing slurries with a variety of solids concentrations and size ranges.

- Have fairly low maintenance and operational costs for the mechanical equipment.

- Provide a kneading action by the rake mechanism which is beneficial to the compression process.

In addition, high-rate thickeners have some advantages over conventional thickeners , such as—

- Smaller lateral space requirements (i.e., lower installation costs).

- Greater throughput of solids based on available area for settlement.

Gravitational thickeners, though, do have some drawbacks, which include—

- Requirements for large spaces.

- Necessity for large watertight basins.

- Sensitivity to persistent strong winds, especially for very large units.

- Expensive operation if large amounts of flocculants are needed to obtain the desired concentration.

Multiple-Plate Thickeners

Innovations have been made to reduce the space needed for gravity thickeners. First among these is the multiple-plate thickener, which uses a series of evenly spaced Inclined plates positioned in a settling tank.

Multiple-plate thickeners are in use by the minerals industry around the world for clarifying, classifying, and thickening. In the United States, this equipment is being used in the coal industry for dewatering the waste products of coal cleaning.

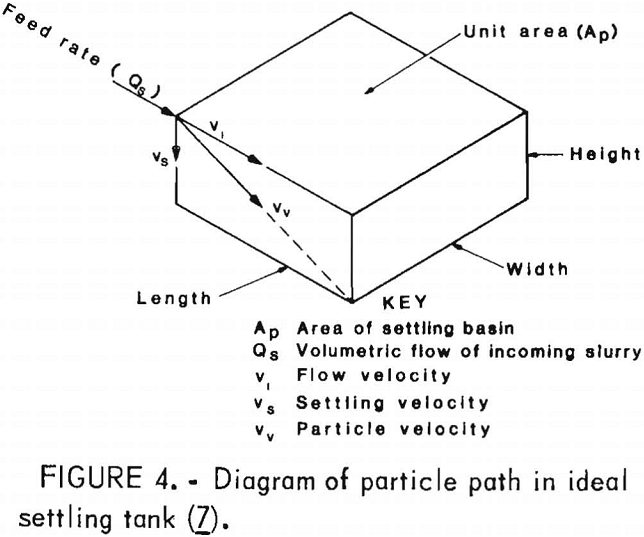

The multiple-plate thickener can be used to accomplish both free settling and hindered settling; however, for simplicity, only free settling will be discussed in describing the theory of operation. For an ideal settling basin, the thickener feed enters at one end of the basin, flows uniformly along its length at velocity Vl, and exits at the other end (fig. 4). Any one particle will settle at velocity vs. The actual trajectory of the particle is indicated by the vector vv. If the trajectory takes the particle to the bottom of the basin before it reaches the far end, then the particle is assumed to have been removed from the liquid. A particle starting at

the top must settle to the bottom at velocity vs in the same time or less than the velocity of the liquid, Vl, in the basin. Thus, the feed quantity, Qs, divided by the settling area, Ap, of the basin is known as the overflow rate or surface loading and is often expressed as gallons per minute per square foot. Based on this relationship, all particles are removed that have a settling rate equal to or greater than the overflow rate. It should be noted that the height or detention time of the basin is not one of the main parameters that affect the separation efficiency.

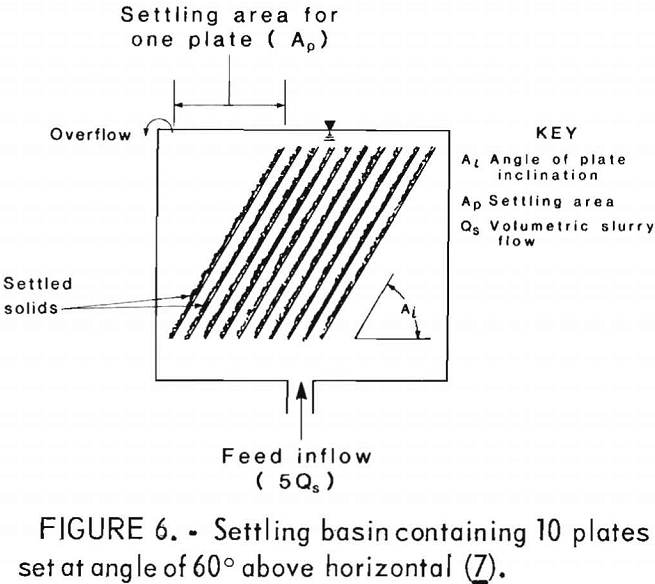

If the depth of the basin is reduced to a few inches and a number of such basins are stacked on top of each other, the result is a simple multiple-plate sedimentation device. Figure 5 shows such a unit containing 10 plates, which can theoretically handle 10 times the flow rate as could the same basin without any plates. The liquid detention time is one-tenth as long, and the settling area is 10 times as large, so the same separation efficiency is achieved because the overflow rate is unchanged.

In practice, the plates are inclined so the settled particles will slide downward and the plates are, in effect, self-cleaning. Figure 6 shows an arrangement of 10 plates set at an angle of 60° above the horizontal. In this case, however, the plate area must be multiplied by the cosine of the angle to correctly determine the capacity and overflow rate, because only the projected area of each plate on a horizontal plane is counted. Thus, the total settling area is 10 times the plate area times cosine 60°, which equals 5Ap, and the capacity of the unit is 5QS. The following equation is used for determining the terminal settling velocity of the smallest grain size just completely retained:

where vs = the terminal settling velocity, feet per second,

Sp = the spacing between plates, feet,

Vl = the feed flow velocity, feet per second,

Lp = the plate length, feet,

and Al = the inclination angle above horizontal of the plates, degrees.

From equation 2, it appears that even at very high flow velocities the finest particles can be retained if the plates are long enough. This is not true, though, because the flow becomes turbulent with high flow velocities. At sufficiently high flow velocities, particles that may have been deposited on the plates will be flushed away when the force exerted on them by the flow becomes larger than the force of gravity on them.

A typical thickener plate is usually 2 ft wide and 10 ft long. Plate spacing is a critical variable because it must be large enough to prevent the settled solids from being disturbed by the upward flowing liquid but close enough to give the benefit of compactness. A 2-in spacing between plates is generally safe and is often used. The plate angle is another critical variable because the angle must be steep enough for the solids to flow or slide down the plate easily. For mineral- type solids having a high specific gravity, 45° is adequate; however, application experience is the best guide in this area.

Types of Multiple-Plate Thickeners

Two different types of multiple-plate thickeners are available. Each type differs according to the direction of the feed flow in relation to the inclination of the plates. The first type operates using the counterflow principle, where the feed material rises between the inclined plates against the direction of inclination, as described in the previous section, to develop the principle of multiple-plate sedimentation. Figure 7 shows a cross section of a typical countercurrent thickener and its component parts. Note that the feed inflow line extends to the center of the tank in order to distribute the feed evenly to all plates.

The second type of multiple-plate thickener uses the crossflow principle (fig. 8). The incoming slurry flows across the width of the inclined plates. The terminal settling velocity for the solids is determined from the equation

where the variables are the same as those defined for equation 2. The crossflow multiple-plate thickener is more efficient in small-particle separation and allows higher feed velocities than the counterflow model. This is because the directions of the feed flow and the solids flow down the plate are perpendicular and not opposed to each other as in the first type. There are practical limits to the highest velocities

possible because the very fine solids may not have sufficient time to settle to the plate at very high feed velocities.

Advantages and Disadvantages of Multiple-Plate Thickeners

The multiple-plate thickener is simple in design and operation. The only item requiring operator attention is the sludge withdrawal rake located at the underflow outlet. This is usually controlled by a variable-speed, positive displacement hopper, which is manually or automatically set by a detector monitoring the sludge level in the hopper.

Spacing and inclination of the plates are very critical for an efficient operation; however, once these parameters have been determined, the multiple-plate thickener can reduce the space requirements by as much as 90 pct compared with conventional thickeners. Multiple-plate thickeners are simple in construction and can be prefabricated for rapid erection. These thickeners are normally constructed of mild steel or 3/16-in stainless steel. For corrosive slurries, polyvinylchloride (PVC) or fiberglass-reinforced plastic plates can be used with rubber-lined tanks.

Sizing Thickeners

Settling Rate Basis

The sizing of thickeners can be done using the method proposed by Coe and Clevenger. When the suspending fluid is water, the area necessary for particle settlement can be estimated by the following formula:

Acs = 1.333(Wrs – Wrd)/Sf………………………………………………………(4)

Where Acs = the cross-sectional area of the basin, square feet per ton of dry solids thickened in 24 h,

Wrs = the weight ratio of water to solids in the slurry,

Wrd = the weight ratio of water to solids in the discharge,

and Sf = the settling rate for a given Wrs, feet per hour

This equation uses various values of Wrs obtained from batch sedimentation tests. The procedure for these tests begins by mixing the solids to be tested in a graduated cylinder of water at a specific water-to-solids ratio, Wrs. The cylinder is shaken, and the fines are allowed to settle. The settling rate, Sf, is the subsidence rate for the solids in the bottom of the cylinder. Several values of Wrs should be tested, including the final discharge value, Wrd. The largest area, Acs, obtained will govern the size of the settling basin or number of settling plates.

The capacity of a thickener can then be estimated by using the equation proposed by Deane.

where Vsc = the volume of solids in compression, cubic feet per ton of solids per 24 h,

ths = the holding time for the solids to settle from the entering dilution of com-compression to the dilution of the discharge, hours

Sgs = the average specific gravity of the solids

Sgw = the specific gravity of water, which is 1.0,

and Sgsc = the average specific gravity of the solids in compression.

The foregoing analysis assumes that the settling rate is dependent only on the feed solids concentration. Running settlement tests with different solids concentrations will indicate the settling rates at different depths in a thickener tank. Talmadge and Fitch proposed another method based on the work done by Kynch. This method uses just one settlement test and provides an estimate of the coincident settling rate and solids concentration for various depths.

In this analysis, a slurry having the anticipated solids concentration of the full-scale operation is put into a tall cylinder. The height of the interface between zones A and B is recorded at frequent intervals. From these data, a graph of the interface height versus time is plotted as shown in figure 9.

The relationship among solids concentration, particle settling velocity, and interface height is shown by the following equation:

where Cse = solids concentration at time te, pounds per cubic foot,

Css = solids concentration of the feed slurry, pounds per cubic foot,

Habo = original height of A-B interface, feet,

Habe = height of A-B interface at time te, feet,

vs = solids terminal settling velocity, feet per hour,

and te = an arbitrary time after solids settlement begins, hours

The solids settling velocity, vs, is the slope of the tangent to the curve for interface height versus time at time te. The quantity Habe + vs te is the intercept of the tangent with the ordinate.

When the feed inflow rate, feed solids concentration, and underflow solids concentration are established, the area of the thickener tank can be determined from the formula—

where Acs = tank area, square feet,

Qs = Volumetric feed rate, cubic feet per hour

and Csu = solids concentration of underflow, pounds per cubic foot.

A series of solids concentration and settling velocity values can be deter-mined from the interface height versus time curve. These values can then be used to establish and plot the solids concentration at different times. Several thickener areas are calculated using the corresponding values of vs and Cse. A graph of Acs versus vs can then be plotted. The maximum value for Acs will be used for designing the thickener.

After the required area has been established the depth of the compression zone can be determined based on the retention time of the solids in this zone. This time is dependent on the rate of discharge and the concentration of the underflow. These values can be obtained from the circuit required for the underflow solids concentration and from the interface versus time graph.

The volume and the height of the compression zone can then be computed:

where Vsc = volume of the compression zone, cubic feet,

ths = retention time, minutes,

Ds = density of the slurry solids, pounds per cubic foot,

Cave = average slurry solids concentration, pounds per cubic foot,

and Dl = density of the slurry liquid, pounds per cubic foot.

The total height of the thickener tank can be determined by allowing 2-½ to 5 ft above the compression zone for the solution in the clarified and transition zones.

Of the two methods discussed, the Kynch method is more often used for flocculated slurries. It must be remembered that these equations will provide only approximate values for sizing a conventional thickener. Pilot plant experimentation must be done using the slurries to be thickened in order to determine the optimum design features.

Solids Flux Basis

The Coe-Clevenger and Kynch methods have been used many years for designing settling tanks; however, they have limitations because they are used to design a dynamic process based upon data obtained from a static settling test. A recent innovation for designing gravity settling equipment uses the solids flux concept.

Solids flux is defined as the mass rate of solid flow through a unit area and portrays the conditions in a modern continuous process gravitational thickener. The solids flux in a batch settling test is dependent only upon the velocity of the settling particles. In a continuous thickener, however, the solids flux is dependent not only on the settling velocity but also on the bulk transport of solids in the underflow. This can be represented as

where Fts = the total solids flux, pounds per square foot per hour,

Fbt = the bulk transport flux component based on the underflow, pounds per square foot per h,

Fs = the settling flux component, pounds per square foot per hour.

Vbt = the bulk transport velocity of the solids, feet per hour,

vs = the settling velocity of the solids, feet per hour,

and Css = the solids concentration of the slurry, pounds per cubic foot.

Figure 10 shows a graphic relationship among the various components of the solids flux for a continuous gravity thickener. This graph can be constructed for any gravity thickener, once the underflow rate and the bulk transport velocities have been determined.

The figure indicates that for low solids concentrations, most of the total flux is composed of the settling component. As the solids concentration is increased, the bulk transport component represents a correspondingly greater portion of the total flux. When the total flux is less than the solids handling capacity, there is only one associated value of solids concentration, and there will be a zone of constant concentration for any particular underflow rate. If the total flux is greater than the solids handling capacity, there will be two zones of constant concentration for any particular underflow rate, but the solids handling capacity represents the maximum practical value for stable thickener operation.

Mathematical manipulation of the variables indicates that

where Csu = the solids concentration of the underflow, pounds per cubic foot.

When designing a thickener, the total solids flux, Fts, and the underflow solids concentration, Csu, will be known or fixed, but the settling flux component, Fs, and solids concentration,

Css, will be unknown. Using values for Fts and Css and picking values for Csu, equation 11 can be used to obtain corresponding values for Fs. A graph of the settling flux, Fs, versus concentration, Css, can then be constructed, as shown in figure 10.

If values of Css and the corresponding Fs are plotted as shown in figure 11, the result is a straight line with a slope of -Fs/Csu and an intercept of Fsl. This is referred to as the operating line and represents the thickening characteristics for a particular thickener at any specified underflow rate. The batch flux curve can also be plotted, and the intersections of the operating line and the batch flux line indicate those solids concentrations that satisfy both relationships.

In figure 11, an operating line has been plotted for a thickener that is functioning within its limits. In this example, only one zone of concentration exists at Cssl to produce an underflow concentration, Csul. If, however, the slurry concentration and the underflow concentration are increased to Css2 and Csu2, respectively, the operating line intercepts the tangent to the batch flux curve and a second zone of concentration

begins to appear with a concentration of Cs2. This condition represents the limiting solids handling capacity of a thickener at a particular underflow rate.

In practice, the necessary data are obtained by running tests using a thickener and the slurry to be thickened. Altering the applied flux, Fts, and the underflow concentration, Csu, will provide an indication of the limiting flux value. After the maximum value of Csu has been determined, a tangent to the batch flux curve can be drawn. The area of the tank can then be determined by dividing the maximum rate of solids loading by the limiting flux. Experience has shown, though, that the optimal thickener throughput will be about 90 pct of the values calculated.

As with conventional thickeners, the use of a pilot plant is also necessary for determining the best size for a high- capacity thickener and for establishing the amount of flocculant needed for proper thickening. The properties of the slurry and the many available flocculants will vary considerably, so the best flow rates and flocculant injections should be determined experimentally.

Multiple-plate thickeners should also be sized according to results of laboratory and pilot plant testing. The results will aid the designer in determining the settling rate of the solids so that the overflow rate and effluent quality can be established. The sludge volume can also be determined in order to establish the underflow solids concentration. Finally, the need for chemical pretreatment can be evaluated.

Centrifugal Sedimentation

Background

Centrifugal sedimentation depends on the density difference between solids and liquids where the particles are subjected to centrifugal forces that make them move radially outwards or inwards through the liquid, depending on whether they are heavier or lighter than the liquid. Centrifuges are compact machines and are capable of producing high liquid clarification and solids concentration. Most of the units available today are designed for continuous operation.

Centrifuges have relatively modest capital costs, but they may be expensive to operate because of the need for chemical conditioning in most applications, high power consumption, and extensive maintenance requirements. Lower speed units consume less power and, as a result, have fewer wear problems. Maintenance difficulties can be greatly reduced if the construction materials are specified to match the abrasive or corrosive characteristics of the slurry to be handled.

A large variety of centrifuges are available on the market; however, several types are used primarily for clarifying and not dewatering, so they are not included in this report. Solid-bowl, screen-bowl and disk centrifuges are of interest in dewatering slimes and are discussed in the following sections.

Solid-Bowl Centrifuges

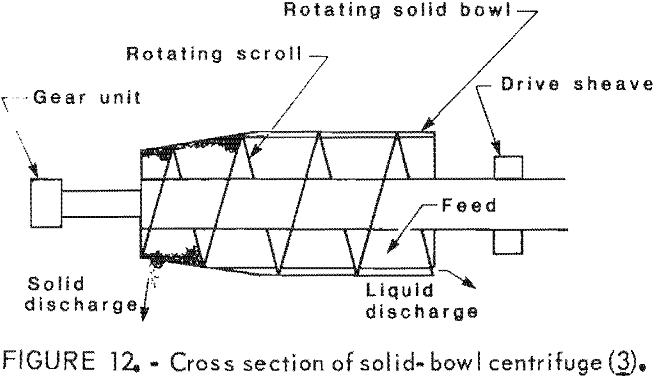

Solid-bowl, scroll, or decanter centrifuges consist of a horizontally rotating chamber that has one end tapered into a cone. The slurry is admitted through axial feed tubes arid removed radially out of the bowl. A screw or scroll mechanism rotates in the same direction as the bowl but 5 to 100 rev/min faster or slower than the bowl and thus can push the solids along the length of the chamber. The speed of the bowl rotation can vary from 1,600 to 6,000 rev/min. The solids are collected by the scroll towards the tapered end of the bowl, while the solution overflows a weir at the other end. The tapered section serves as a drying zone or beach area prior to the cake discharge. Figure 12 shows a simplified cross section of a typical solid-bowl centrifuge.

With regard to the machine design, a number of variations are available in the contour of the centrifuge shell, scroll flight angle and pitch, beach angle and length, conveyor speed, and feed position, An alternative to the liquid overflow outlet is an internally mounted tube for skimming off the liquid.

Specially designed models of this centrifuge have been used to dewater very fine slurries in hydrocyclone circuits for recovering and dewatering deslimed coal. Other solid-bowl centrifuges have been used to dewater froth flotation tailings after thickening in a static thickener. Another major area of application for this type of centrifuge is in the classification of solids such as kaolin clay and titanium oxide.

Polyelectrolytes are widely used for the flocculation of the solids to be

dewatered in solid-bowl centrifuges. The point of addition varies, depending on the type of the polyelectrolyte and slurry. Anionic polyelectrolytes are usually introduced upstream from the centrifuge, while cationics are added within the centrifuge because they react very quickly with the slurry.

Wilson and Miller compared the effectiveness of solid-bowl centrifuges to that of disk vacuum filters and commented on the parameters that affect their use in coal dewatering. The solid-bowl centrifuge and the disk vacuum filter produced similar results on the same slurry. The solids from each of the two dewatering machines contained 20 pct minus 325 mesh with 20 pet surface moisture and a centrate or filtrate of about 0.1 to 0.2 pct solids. The products from these units are very similar in nature, so the choice between the devices should be made on the basis of handling characteristics , throughput, floor space, cost, and overall circuit or layout considerations. If the centrifuge is chosen, in-plant adjustments to feed rates, speed, and pool depth can be made to obtain the proper balance of throughput, moisture, maintenance cost, and effluent clarity.

Wilson and Miller also found that steam-heating the feed to 110° F resulted in a 4-pct reduction in product moisture; however, higher temperatures did not further improve results. The use of heat may be economically feasible as a means of reducing the product moisture if an inexpensive source of heat is available.

One of the principal advantages of this machine is that it can dewater dilute slurries. In plants that use shaking tables, no dewatering screens are required between the table and the centrifuge as would be needed when a screen-type machine is used. The solid-bowl unit will require more horsepower, though, because it must accelerate the water as well as the solids during the dewatering operation.

Screen-Bowl Centrifuges

Screen bowls, als0 called basket or perforate units, are a second type of centrifuge. Positive-discharge machines are screen-bowl centrifuges with transport devices and are the most common type of centrifuge found in the minerals industry today. These units have two elements that rotate about a vertical or horizontal axis. These elements consist of an outside conical screen frame and an inside solid cone that carries spiral hindrance flights. A gear arrangement produces a differential speed in the two rotating elements so that they both rotate in the same direction, but the screen element moves slightly faster than the cone carrying the spirals. The operation is similar to that of the solid-bowl centrifuge. The slurry enters the machine at the top and falls on the apex of the cone. The centrifugal force developed by the rotating cone throws the solid-liquid mixture against the screen. The water passes through the perforations and is collected in an effluent chamber. Meanwhile, the flights spiral downward and the solid material is gradually transported to the bottom of the screen. The conical shape of the basket causes the solids and water to be subjected to zones of increasing centrifugal force. Figure 13 shows a cross section of a typical screen—bowl centrifuge.

Another type of screen-bowl centrifuge is the vibrating-basket type that is frequently being installed in new plants. This centrifuge has either a vertical or horizontal basket that vibrates in such a manner as to cause the solids to move through the machine. This vibration tends to loosen the bed of particles so that they are free-draining and only moderate force is required to effect thorough dewatering. Because of the low speed generally used in these centrifuges, the moisture content of the solids is usually higher than that produced by the transport-type unit; however, wear and horsepower are low and solids degradation is minimal. The principal difference between the horizontal and

vertical screen-bowl types is that the horizontal axis machine requires less headroom than the vertical device.

Wilson and Miller also conducted tests on screen-bowl units. They found that the positive-discharge screen-bowl centrifuge provided 4 to 6 pct lower moisture in the solids product than the solid-bowl centrifuge, Thus, for similar sized centrifuges, the screen bowl is preferable to the solid bowl for this particular in¬stance, As with the solid-bowl centrifuge, they found that the screen-bowl centrate must be bled out of the plant to a pond or backed up by a secondary recovery system. Because of the recovery requirement, this type of centrifuge should operate for maximum moisture reduction as opposed to maximum effluent clarity to fully benefit from this costly system.

Further test results indicated that only minor moisture reduction was obtained by steam heating the feed, so heating was not recommended for this type of centrifuge, Surface-tension-reducing chemicals and a flocculant were also tested; however, both approaches were ineffective in reducing moisture.

Disk Centrifuges

The last type of centrifuge to be discussed is the disk centrifuge. Its construction is similar to that of the vertical screen-bowl unit; however, instead of using just one cone. It uses multiple cones for dewatering (fig. 14). The basic idea of increasing the settling capacity by using a number of disks in parallel is the same as the multiple-plate principle in gravity sedimentation.

The slurry enters the unit at the top, and the solids are forced to the outer circumference by centrifugal action, then removed through the outer rim. The clarified water is channeled upward through passages between the disks. These centrifuges can handle inflows of up to 3,300 gal/min containing low-density particles up to 0.1 in in diameter and concentrations to about 1 pct solids. The output can be up to 6 pct solids, or even up to 10 pct solids if chemical additives are used.

Disk centrifuges are operated at speeds up to 12,000 rev/min, depending on the bowl diameter. The bowls usually have

equal dimensions of height and diameter for optimum capacities, and the angle of the cones is usually between 35° and 50°, which is large enough to facilitate the sliding of the particles on the disk surfaces.

There are several variations in this design, which include recirculating the solids discharge, a facility for washing before discharge, and a paring tube for pressurized solids discharge.

Disk centrifuges are very effective for dewatering fine-grained solids and are often used for dewatering kaolin clay.

Centrifuge Performance

The performance and efficiency of a centrifuge depend on a number of factors. The more important factors are—

- Centrifuge rotation speed

- Diameter.

- Length,

- Beach angle and length (for horizontal centrifuges)

- Feed point of slurry.

- Feed point of flocculants.

- Scroll rotation speed differential and pitch (for positive-discharge units),

- Pool depth (for solid-bowl units)

Increasing the bowl rotation speed usually increases the solids recovery. There may be an increase in the solids cake concentration; however, the increase of the fines in the cake tends to increase the cake moisture. Higher speeds also increase both maintenance and operating costs of the centrifuge.

Centrifuge-bowl diameters generally range from 6 to 50 in, and bowl lengths are generally from two to four times the bowl diameter. Bowl speed is normally a function of the bowl diameter because the effects of speed and diameter determine the resulting centrifugal force acting on the slurry. Typical values for centrifugal force range from 1,000 to 4,000 times the force of gravity; the higher centrifugal forces are associated with the smaller bowl diameters.

The bowl length will affect the centrate clarity. A longer bowl increases the residence time of the slurry as it travels from one end of the bowl to the other. This increased time allows the finer particles sufficient time to separate from the liquid.

In solid-bowl units, the beach angle and beach length will affect both the percent solids in the final cake and the torque needed to move the solids out of the centrifuge at a constant scroll differential speed. The longer the cake is allowed to dewater on the beach, the higher the cake solid concentration, and the higher the torque requirements for discharge.

The feed entry point into the bowl will influence the percent solids in the cake and the solids recovery. For solid- bowl centrifuges, recovery will be improved if the feed entry point is near the beach because the slurry particles have a longer distance to migrate to the end of the machine where the liquid exits.

Chemicals may be added to the slurry to accelerate the flocculation of fine particles that do not immediately separate from the liquid. The high degree of agitation and mixing within the centrifuge generally necessitates large polymer doses to effect an increase in the solids recovery. In one instance, a dosage range of 0.1 to 0.3 lb polymer per ton of solids increased the capacity of a centrifuge 5 to 10 pct at the same solids recovery.

In positive-discharge units, changes in the scroll rotation speed and pitch will affect the solids recovery and cake dryness. Small residence times allow only the heavier and larger solids to be removed, while the finer solids remain suspended in the liquid. This factor will be particularly important when dewatering slimes.

Most solid-bowl centrifuges are provided with an adjustable pool depth setting so that the liquid level in the bowl can be changed after installation. An increase in the pool depth will improve the percentage of the solids that are separated from the liquid. This improvement in solids recovery is due to an increased residence time and a reduction in the agitation within the centrifuge at deeper pool depths; however, deeper ponds will increase the amount of moisture in the cake because of the reduced dewatering time on the beach.

Advantages and Disadvantages of Centrifuges

A main advantage of the centrifuge is its operational flexibility. Within its design limits, a centrifuge can be fed a slurry at various rates and still provide a consistent solids product. If the feed rate exceeds the design limits of the unit, the excess solids appear in the liquid; however, the quality of the discharged cake does not deteriorate and the percent solids remains relatively constant.

A disadvantage of the centrifuge is abrasive wear on the scroll and other interior parts, which results in high maintenance costs. In recent years, scrolls have been manufactured with improved materials such as tungsten carbide on the wearing surfaces. Operational results indicate an order of magnitude improvement in the life of these components. Another drawback of the centrifuge is that the feed slurry may need to be prethickened. Although centrifuges can dewater a wide range of slurries, a very low feed solids content means that the centrifuge must process large volumes of slurry input. The number of centrifuges needed in a dewatering circuit is directly proportional to the volume of feed slurry to be processed. Consequently, the slurry should be prethickened by sedimentation, hydrocycloning, or other means prior to centrifugation. The final circuit configuration will be the result of compromising the performance and economy of the pre-thickening and centrifuge equipment.

Sizing Centrifuges

When centrifuging a slurry, it is not necessarily true that an increased force will decrease the moisture content of the product. Materials that deform, break, or degrade will not be dewatered proportionally to the applied forces. It should also be realized that horse-power, wear, maintenance, and degradation will accelerate with increased forces applied in the machine. While a large centrifugal force developed by a machine may be an indication that it is sturdily built, this force should not be the only criterion used in selecting a centrifuge to dewater any material.

For any particle traveling in a circular motion about a point, the centrifugal acceleration is

Ac = vp²/Rc……………………………………………………(12)

where Ac = centrifugal acceleration, feet per second per second.

vp = the linear peripheral velocity, feet per second,

and, Rc = the radius of curvature, feet

Centrifugal acceleration is then expressed as multiples of the gravitational acceleration:

where vp = 2 RCN, feet per second,

N = the number of revolutions per second,

π = 3.1416,

Fc = the centrifugal acceleration expressed as multiples of gravitational acceleration, dimensionless,

and G = the gravitational acceleration, feet per second per second

Sigma Concept

The “sigma concept” has been widely used in the field of centrifugal sedimentation for the last 30 yr. It is a simplified representation of machine performance in terms of the particle size, the total volumetric rate, and an index of the centrifuge size. The sigma concept characterizes a centrifuge’s ability to separate solids from liquids and is widely used in industry.

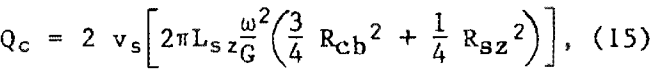

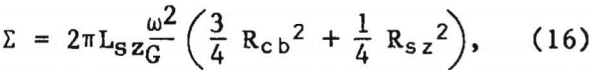

The volumetric throughput of a centrifuge can be expressed as

where Qc = the volumetric throughput, cubic feet per second,

vs = the terminal settling velocity of the solids, feet per second,

ω = the angular velocity of the solids, radians per second,

G = the acceleration of gravity, feet per second per second,

Lsz = the length of the settling zone, feet,

Rsz = the radial length from the rotational axis to the settling zone surface, feet,

and Rcb = the radial length from the rotational axis to the centrifuge bowl surface, feet

This equation is composed of two parts. The first component, vs, describes the settling characteristics of the solids. The remainder of the equation represents the machine variables that effect separation efficiency, such that—

where Σ = the sigma value for a particular centrifuge configuration

Equation 16 is the basic expression of the sigma concept, which gives an estimate of the maximum flow rate that will allow solids of a particular size to separate from the liquid. Sigma is a constant containing factors pertaining only to the centrifuge and can be thought of as the theoretical capacity factor. It is expressed in terms of area and facilitates comparison between the performances of geometrically and hydrodynamically similar centrifuges processing the same slurry.

A shortcoming of the sigma concept is that the cut size or smallest particle separated from the liquid is not suitable as a criterion for separation efficiency because different total efficiencies can be obtained for a given cut size, depending on the size distribution of the solids. The best method of describing the performance of a centrifuge is by using the grade efficiency curve, which is briefly discussed in appendix D. This requires many tests, together with deeper theoretical considerations, but the results will provide more meaningful and reliable predictions of total efficiencies for different slurries.

Pilot-Plant Testing

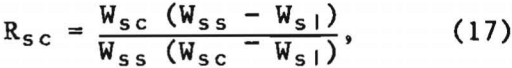

The centrifuge evaluation procedure, generally used in pilot testing, relates the percent of solids recovered and cake solids concentration to the feed rate at various operating conditions. The recovery of feed solids in the centrifuge cake is determined from the measurements of flow rates and concentrations entering and leaving the centrifuge. By combining the material balance equations and the definition of recovery, the following simplified equation relates the recovery to various solids concentrations:

where Rsc = the percent recovery of solids in the cake,

Wsc = the weight percent of solids in the cake,

Wsl = the weight percent of solids in the centrate,

and Wss = the weight percent of solids in the fed slurry.

This equation simplifies the testing procedure so that the solids recovery can be calculated from concentration measurements made on the three process streams entering or leaving the centrifuge. Thus, flow rate measurements need not be made to calculate the recovery of solids in the cake.

Filtration Equipment

Background

Filtration is a process where solids are separated from liquids by passing a slurry through a permeable filter medium that retains the solids. To cause the fluid to flow through the filter medium, a pressure drop has to be applied. The pressure drop can be achieved by various means, including gravity, vacuum, or direct pressure. If the liquid is induced to flow through the medium by hydrostatic head, it is called gravity filtration. If higher than atmospheric pressure is applied upstream from the filter, the process is called pressure filtration; if lower than atmospheric pressure is applied downstream from the filter, it is referred to as vacuum filtration.

There are two types of filtration systems available: surface filters and depth filters. Surface filters are used for cake filtration, where the solids are deposited in the form of a cake on the surface of a relatively thin filter medium. Depth filters are used for deep-bed filtration, where particle deposition takes place within the medium. Surface filtration is the process in common use by the minerals industry and is the only one discussed in this report.

At the commencement of surface filtration, the slurry particles that are the same size as or larger than the openings of the filter medium are held at these openings and create smaller passages, which remove even smaller particles from the slurry, A filter cake is formed which, in turn, functions as a more efficient filter for the subsequent filtration.

In practice, solids are deposited on the filter medium as a cake, which is removed from the filter medium by a mechanical method such as scraping. After the cake is removed, the filter is cleaned by spray washing, then put into position to receive more solids. The performance of filter equipment is usually expressed as the yield in pounds of dry solids per square foot of filter area per hour.

The filter medium is probably the single most important component of a filter that affects equipment performance. Many different materials are now available as filter media. Filter cloth can be composed of duck, chain, and twill weaves, as well as felt made of cotton, nylon, polyester, polypropylene, and other natural or synthetic materials. Filter cloths and screens made of steel, stainless steel, and other alloys are also on the market.

Filter paper is often required as the filter medium to obtain high solids retention. Filter paper requires the support of filter cloth, screens, or perforated metal sheets to prevent its breaking. The filter paper can be easily removed from the support filter medium.

Covering the surface of the filter cloth or filter paper with a filter aid is known as a precoat and is often required to prevent blinding or clogging the filter medium. Materials such as diatomaceous earth, paper pulp, or perlite can be very effective. A filter aid can also be added to the slurry as a body feed to produce a filter cake that remains relatively permeable during the filtration cycle and gives a good overall filtration rate. Various combinations of filter cloth, filter paper, and precoating are capable of filtering out particles as small as 0.0002 in in diameter.

The following sections discuss the filtration equipment commonly used today.