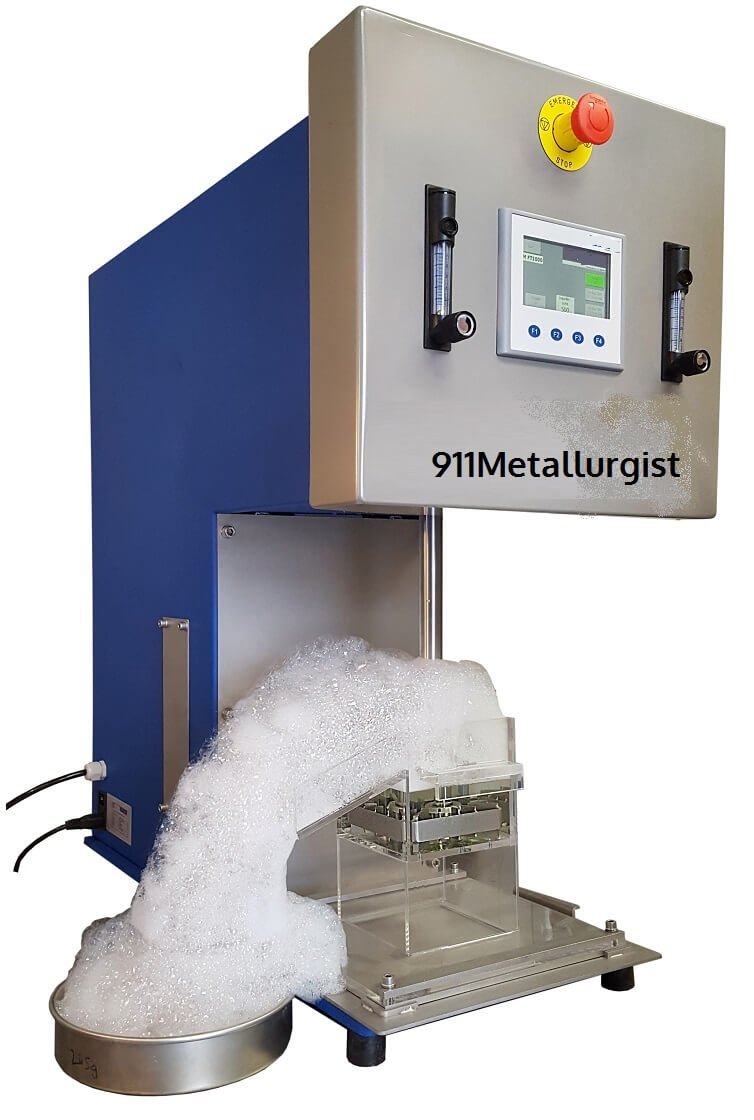

The FC Bond Work Index Test Ball Mill was designed by F. C. Bond for use in determining the Bond Index, a measure of grindability and power required for grinding applications. The FC Bond Mills are used in laboratories throughout the world. A copy of Fred C. Bond’s Method of Crushing and Grinding for determination of the Bond Index is included with each mill. This mill can be used to calculate the grindability of all ores.  This Ball Mill can be used in to grind for a period of time, if plugged into a lab timer, or it can be used for any number of revolutions, according to the type of grind desired. The FC Bond ball Mill comes with table stand (pictured), motor, clutch, revolution counter, motor starter* and controls, 12″ machined steel drum, 44-1/2 pounds of steel balls (Bond Index test), receiving pan and hand screen pan. Our Bond mill is guaranteed to have internal mill dimensions within 0.10” of the 12” x 12” as specified by Mr. Bond. This is important, because the original bond mill was within these specifications and all data derived by Fred Bond was derived from a mill with his specifications

This Ball Mill can be used in to grind for a period of time, if plugged into a lab timer, or it can be used for any number of revolutions, according to the type of grind desired. The FC Bond ball Mill comes with table stand (pictured), motor, clutch, revolution counter, motor starter* and controls, 12″ machined steel drum, 44-1/2 pounds of steel balls (Bond Index test), receiving pan and hand screen pan. Our Bond mill is guaranteed to have internal mill dimensions within 0.10” of the 12” x 12” as specified by Mr. Bond. This is important, because the original bond mill was within these specifications and all data derived by Fred Bond was derived from a mill with his specifications