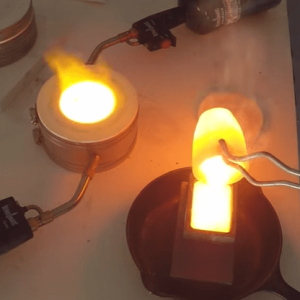

A modular mid-sized propane gas kiln. If the mini kiln is too small for your needs and our 8″ gold smelter too large, the 6″ melting furnace, the perfect size.

Deluxe Kit includes:

6″ round by 7″ tall refractory kiln with 3″ diameter x 4″ tall chamber

1 clay crucible stand

1 Salamander A0.5 clay graphite crucible, which can melt up to a kilo of silver

8″ tongs

Liner maintenance kit

1 lb kiln silver melting flux

1 lb premium gold flux

Graphite combo loaf mold

Graphite 2 oz Gold Loaf Mold (1 oz Silver or Copper) – for smaller pours

NAC-500 Graphite Mini Crucibles – for smaller pours (remove one of the chamber layers)

Jar Liner Restore High-Quality Maintenance Material

Instructionsusa manufacturer

Requires 2 x 4000 BTU Torches Bernzomatic TS4000 or equivalent (not included)