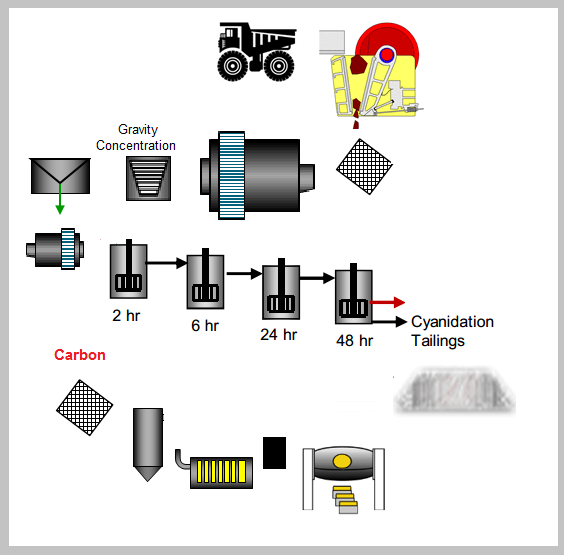

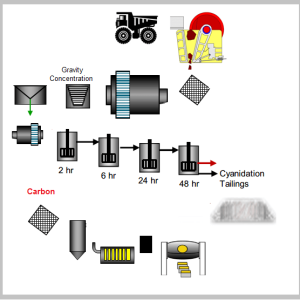

Gravity Gold – Rougher Concentrate Flotation CIL Leaching & Refining: This mineral processing plant is to recover gold from sulphide ore deposits. Provided here are all major equipment for a plant arranged to recover gravity gold, float a gold rich sulphide concentrate, liberate the sulphide hosted gold with a light regrind and dissolved its precious metals using the Carbon-in-Leach process. The CIL process with activated carbon is best suited for ores with no or some levels of preg-robbing carbonaceous material. The initial gravity circuit will extract any coarse GRG gold and silver. More difficult (refractory) ores may need deeper ultra-fine regrind prior to leaching as well and more elaborate processing, not included here.

This simple metallurgical concentrator includes single stage crushing, conveying, primary grinding, spiral classification, gravity concentration, slurry pumping, rougher and cleaner (optional) flotation banks, regrind mill, cyanide leaching tanks, loaded carbon stripping and regeneration as well as refining facility.

With this simple flowsheet, you will recover silver and/or gold into a bullion bar.