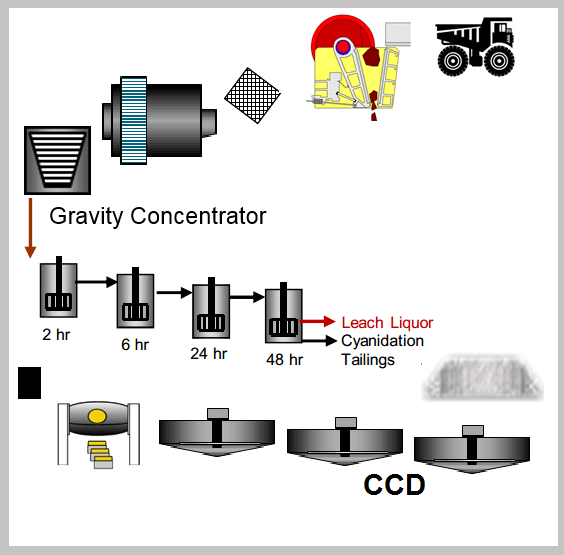

Gravity Recovery & Au/Ag Leaching – CCD Merrill Crowe Plant & Refinery: This complete hydrometallurgical process plant is for recovering precious metal from oxide or very low sulphide ore deposits containing silver and/or gold more commonly. The turnkey plant is for the recovery by cyanidation leaching from ores absent of preg-robbing carbonaceous material. The initial gravity circuit will extract any coarse, slow leaching gold and silver. The simple Merrill-Crowe technology best deals with high grade gold and/or silver deposits.

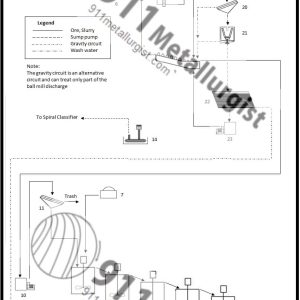

This simple metallurgical concentrator includes single stage crushing, conveying, primary grinding, spiral classification, gravity concentration, slurry pumping, cyanide leaching tanks, counter-current decantation circuit, Merrill-Crowe precipitation and refinery.

With this simple flowsheet, you will recover silver and/or gold into a bullion bar.