Likely the Best Fine Gold Recovery Equipment based on the enhanced centrifugal forces, like the Falcon Concentrator, has a maximum capacity of 150 t/h. The concentrator has proven effective in various minerals sectors link gold, Cu, Sn, Coal, Iron ore, Ag, Heavy mineral and most significantly tantalum where Falcon has achieved excellent results.

ADVANCED GRAVITY TECHNIQUES

Gravity concentration technique is the most simple and economical of all methods of concentration applied in mineral processing. It permits the recovery of values at coarse a size range as possible. The separation of mineral particles are generally based by exploiting the difference in density between the two minerals. At present, the gravity concentration technique is widely used for the treatment of various traditional raw materials. Tin. tungsten, chromite, iron ore, coal as well as the heavy mineral of alluvial or beach sands etc. are commonly processed by this technique. Now days lot of new and advanced equipments have been developed to separated the finely divided minerals from the gangue materials. Some of them arc reviewed here.

The Falcon Concentrator is a Fine Gold Recovery Equipment made of a rotating bowl with the smooth inclined wall. The feed slurry enters the bottom of the bowl and gets stratified along the bowl wall. The heavier material settles on the wall while the lighter particles are pushed to the lip of the bowl and discharged as the overflow. The heavier fraction settled on the bowl wall is continuously removed through a nozzle located at the top of the bowl.

Gravity concentration is the oldest beneficiation technique adopted by the mankind. Gravity concentration is simple, cheap and efficient to treat coarse high-grade ores. However the low-grade ores need to be reduced to fine sizes for better liberation and traditional gravity concentration techniques are not capable of treating fines. After the invention of froth flotation in the beginning of 20th century, gravity concentration was pushed to the back seat. But the gravity concentration made a comeback by the end of 20th century due to:

The advanced gravity concentration techniques essentially use centrifugal force to provide enhanced gravity to efficiently treat fines. Some of the successful Enhanced Gravity Concentration technologies and Fine Gold Recovery Equipment that found application in the mineral processing industry are Falcon Concentrator and Mozley Multi-Gravity Separator.

As a Fine Gold Recovery Equipment, the Falcon concentrators rely on a rotating bowl to generate high centrifugal accelerations similar to Knelson concentrators. The feed slurry rises upward over a slightly inclined smooth wall Stratification of higher-density particles occurs toward the bowl wall, and lower-density particles move toward the center of the bowl. Different models vary in the way they collect and produce the concentrate

In the semi-batch Fine Gold Recovery Unit, the upgraded product that has been forced against the bowl wall is made to move into a vertical, fluidized collection zone in the upper portion of the bowl. The collection zone consists of a number of rings that have pressurized water injected from the back, effectively elutriating and cleaning the concentrate that sits in these collection rings until a rinse cycle begins. These machines are known as semi-batch devices because they continually accept feed during the run cycle but only produce concentrate during periodic rinse cycles. Run times range from 30 minutes to several hours depending on the application, while the rinse times are generally less than a minute. The throughput rates range from 1 to 400 t/h The centrifugal accelerations range from 50 to 200 G These units are mainly used in precious metal recovery plants.

In continuous devices, at the top of the bowl is a ring of specially designed concentrate flow hoppers, followed by pneumatically controlled variable orifice valves. These valves allow for a constant stream of concentrate to be produced. The continuous Fine Gold Recovery concentrator is able to vary mass pull to concentrate by adjusting valve orifice size through changes in air pressure. Because of their high mass pull rates of 5% to 40%, these units are used in the recovery’ and upgrade of tin, tantalum, tungsten, chrome, cobalt, iron, fine oxidized coal, and uranium ores. The ultrafine units are designed to concentrate material below 50 um at less than 20% solids and may be typically used in deslime cyclone overflow streams.

The Falcon concentrator is another spinning batch Fine Gold Recovery Equipment designed principally for the recovery of free gold in grinding circuit classifier underflows where, again, a very small (<1%) mass pull to concentrate is required. The feed first flows up the sides of a cone-shaped bowl, where it stratifies according to particle density before passing over a concentrate bed fluidized from behind by back-pressure (process) water. The bed retains dense particles such as gold, and lighter gangue particles are washed over the top. Periodically the feed is stopped, the bed rinsed to remove any remaining lights and is then flushed out as the heavy product. Rinsing/flushing frequency, which is under automatic control, is determined from grade and recovery requirements.

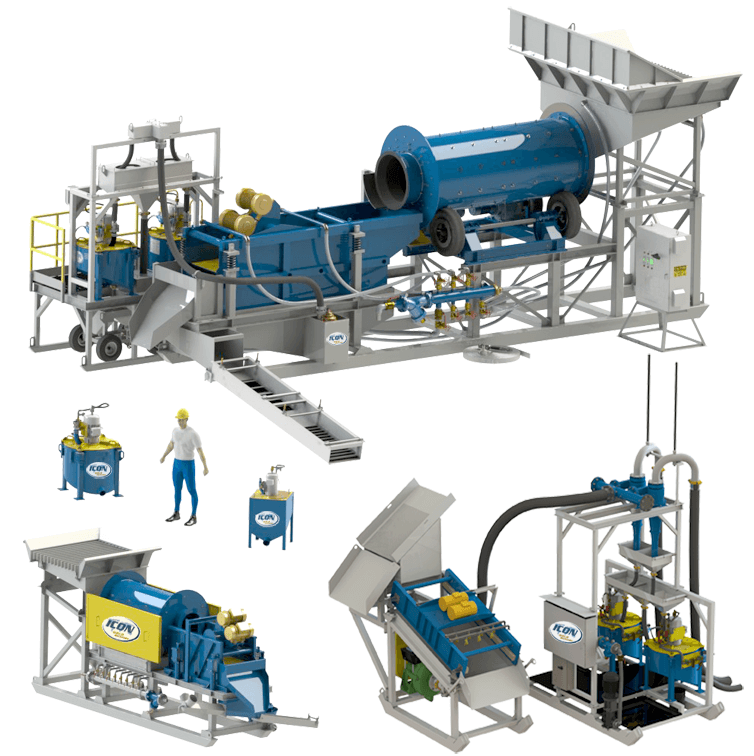

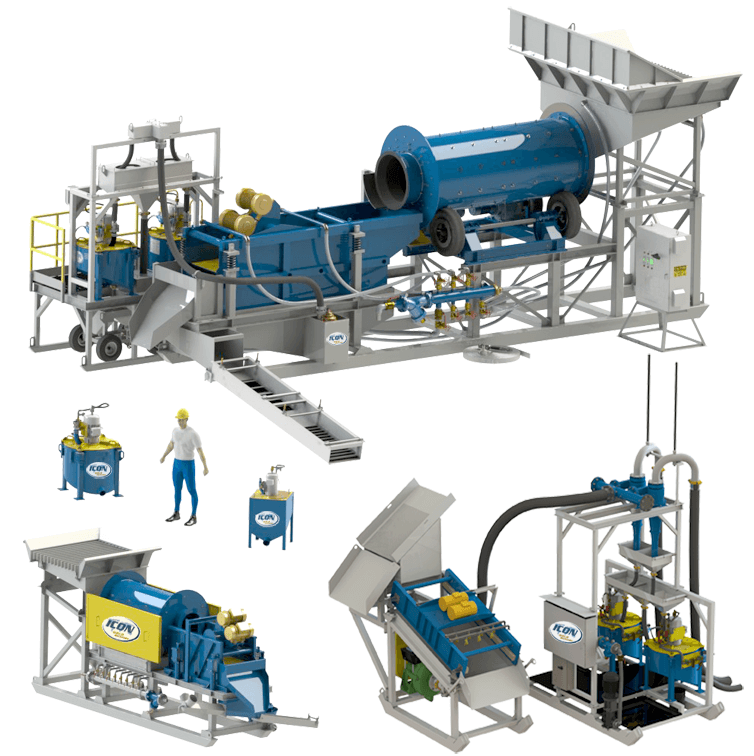

The units come in several designs, the Semi-Batch (SB), Ultrafine (UF), and i-Con. designed for small scale and artisanal miners.

These batch centrifugal concentrators have been widely applied in the recovery of Fine Gold, platinum, silver, mercury, and native copper.

|

|

|

|

|

|

![]()

Images for illustration purposes only. No rights can be delivered from the illustrations.

911METALLURGY CORP. can not be responsible for errors in typography or photography.

Copyright 2012-2024 911Metallurgist | All Rights Reserved