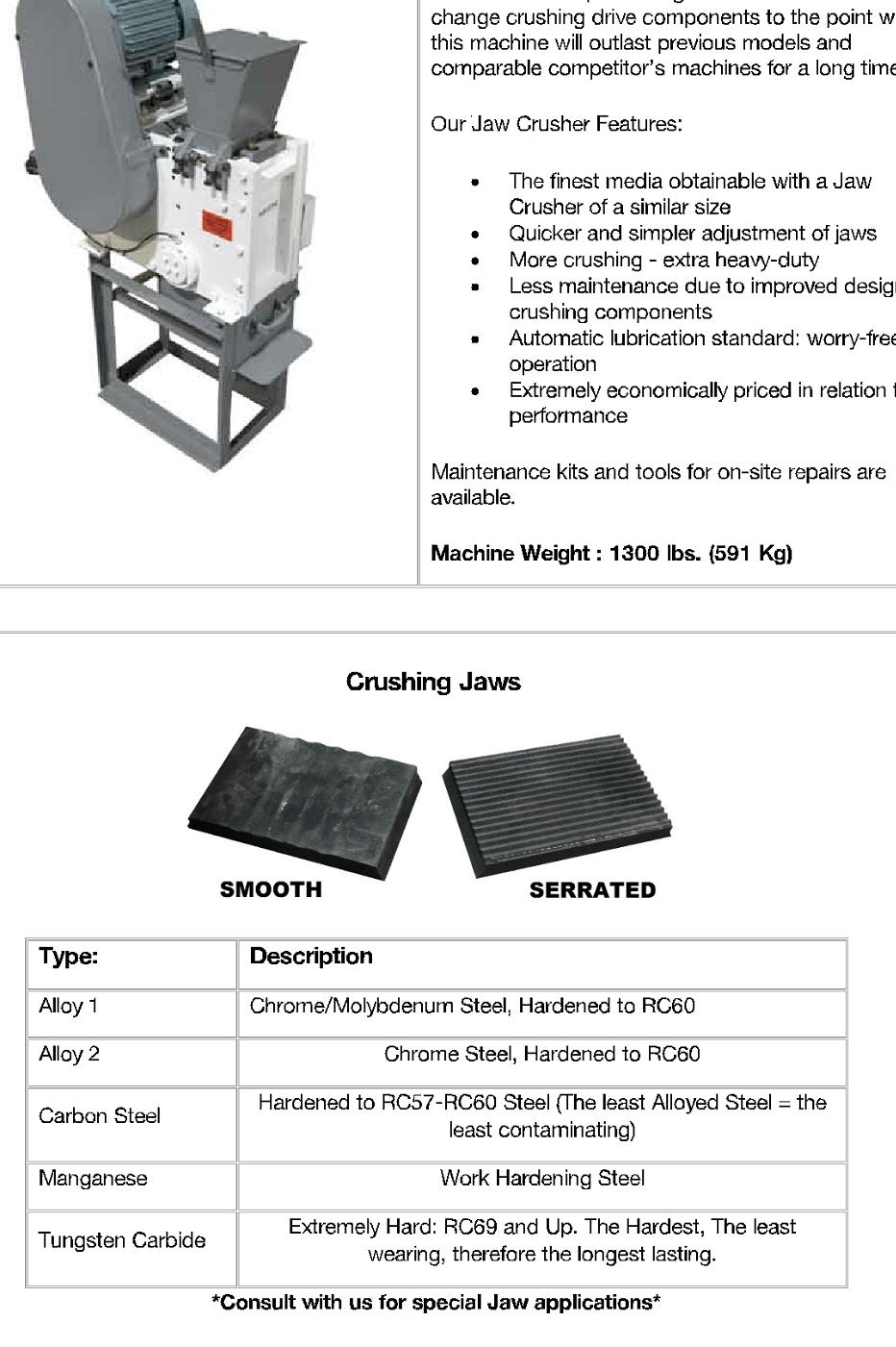

The 911MPETMBT75 is our largest Laboratory Jaw Rock Crusher and is based on our world-renowned High Reduction Ratio Jaw Crusher; the 911MPETMBT75 has been engineered to handle the toughest crushing requirements. With an input gap opening of approximately 7-1/2” x 7-1/2” ( 191 mm x 191 mm), this machine will crush larger rocks and/or any other dry material faster than any other Jaw Crusher in the market of its size.

- Design options are available per customer requirements.

Power Options:

3 Phase / 60 Hz

7.5 HP or 10 HP Motor Single Phase and/or 50 Hz Motors Available

Voltage Options:

208, 220, 230, 240, 380, 415, 440, 460, 480, 575, 600

Explosion Proof Available for Special Applications