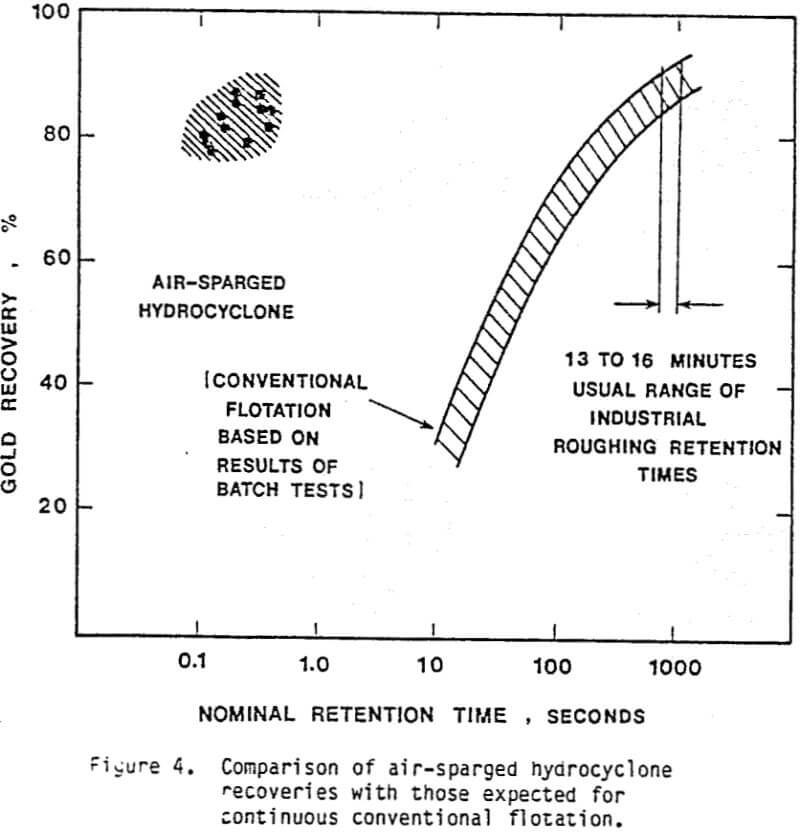

Pilot-scale tests indicate that effective concentration of fine gold from Colorado River sands can be achieved by flotation with the air-sparged hydrocyclone. The fine sands (55% minus 400 mesh and 0.01 opt) from gravity concentration were processed with a 5-cm air-sparged hydrocyclone (capacity -1.0 tph dry solids). Concentrate grades as high as 5.0 opt were produced in a single stage at a recovery of 75.0%. The separation efficiency was significantly better than that achieved in conventional batch flotation experiments.

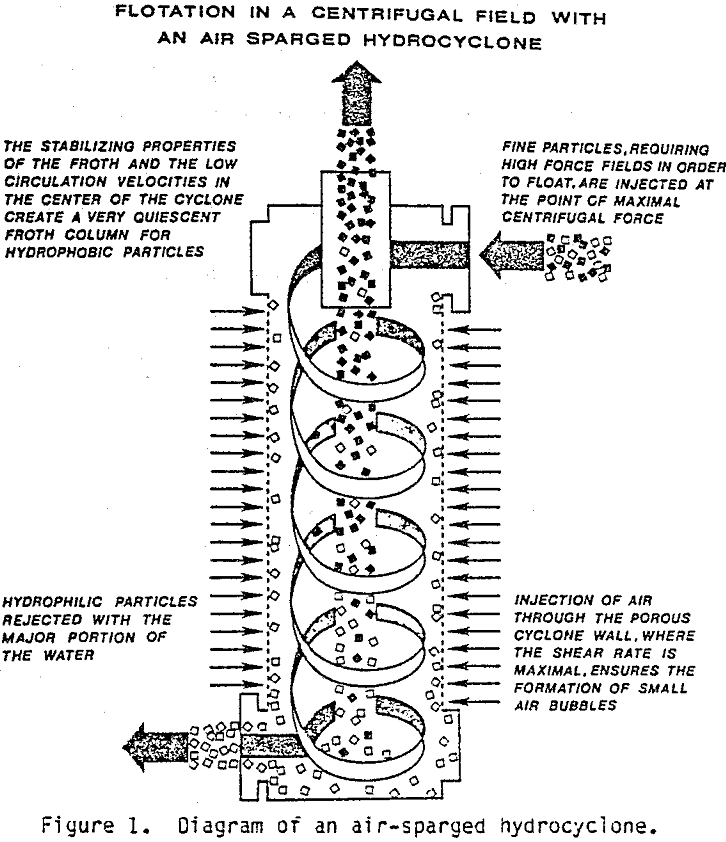

The air-sparged hydrocyclone was envisioned to take advantage of a high centrifugal force field developed by swirl flow in the cyclone and a high density of freshly formed small air bubbles in order to achieve fast flotation of fine particles. The basic features of the air-sparged hydrocyclone include a porous cylindrical wall through which air is sparged and a swirl flow of slurry orthogonal to the air flow.

Unlike conventional flotation cells, in the air-sparged hydrocyclone, particle/bubble interaction is directed and occurs in the swirl layer at the surface of the porous wall. Further, the bubble number density is tremendously increased because of the air-sparged system. Both these factors contribute to an increase in the overall flotation rate to such an extent that retention times of less than a second have been shown to be sufficient for satisfactory separation.

Pilot-plant tests in South Africa are in progress and have shown that the air-sparged hydrocyclone can be used effectively for pyrite flotation (minus 48 mesh) from a low-grade ore. Recoveries approaching 90 percent and a concentrate grade of about 75% FeS2 have been reported for a single-stage operation.

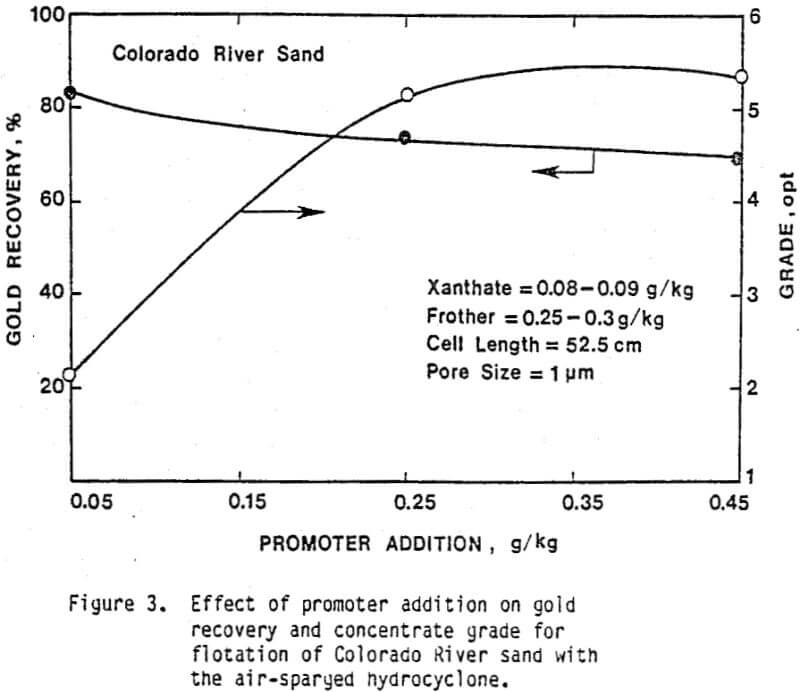

In any event, flotation reagents generally will be required for effective gold flotation. In this study reagents used for flotation of the placer gold ores in the 5-cm diameter air-sparged hydrocyclone included Aero 343 xanthate (collector), kerosene (promoter), and Dowfroth 1012 (frother). The feed was conditioned with appropriate amounts of these flotation reagents in a sump for 20 minutes prior to the initiation of a test.

With a collector addition of 0.08 g/kg, a promoter addition of .05 g/kg, and a frother addition of 0.1 g/kg, more than 80 percent of the gold is recovered at 2.17 opt gold. For comparison, the results from conventional batch flotation are given. Note that both the grade and recovery are significantly better for the air-sparged hydrocyclone test than the grade and recovery for the conventional batch flotation test. As mentioned earlier, promoter and collector were found to significantly influence the flotation recovery of gold.

Successful recovery of gold from the Colorado River sand (0.01 opt) can be accomplished by fast flotation with the air-sparged hydrocyclone. Sold recoveries exceeding 75 percent at grades of 2 to 5 opt were obtained. The separation efficiency achieved with the air-sparged hydrocyclone was superior to that achieved by conventional flotation.