Table of Contents

Separating a mixture of particle sizes of material suspended in a liquid medium is by no means an exact science. Selecting machines for individual classifying operations is even more difficult. The plant operator’s own background is of course invaluable, and considerable help may be obtained from technical articles, talks with sales engineers, and handbooks on ore dressing. These several sources of information, however, are difficult to marshal in proper perspective for the major decision on classification units that an operator may be called upon to make. To the present writer’s knowledge this assembly of facts is not available in handbooks, and technical papers are scarce on classification equipment developed in the past five or six years. It is believed that this paper will be helpful to users of classification equipment at this particular period in the development of hydro-classification.

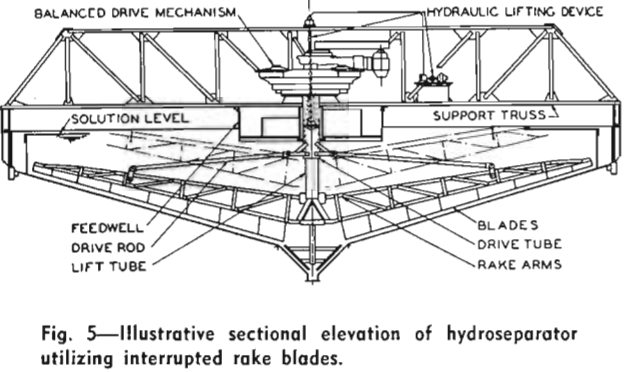

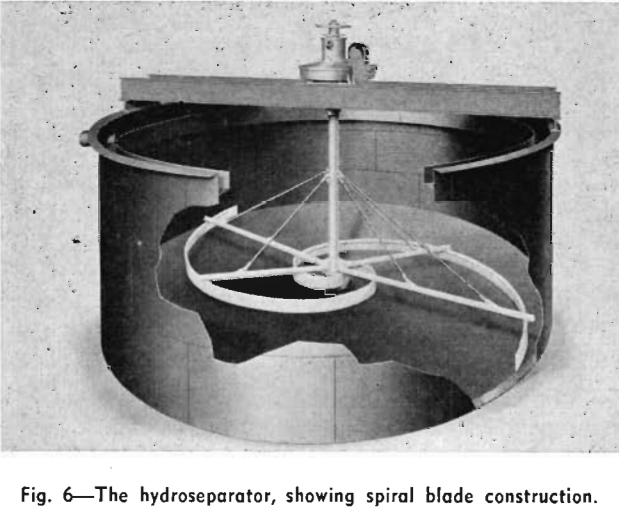

The hydro separator is a circular tank equipped with slowly rotating rake arms, set on a slope, with interrupted rake or spiral blades to move the settled solids to a central discharge cone. Tank diameters vary from 4 to 250 ft. Tank depths at center are 2 to 3 ft for small units and up to 25 ft for larger units.

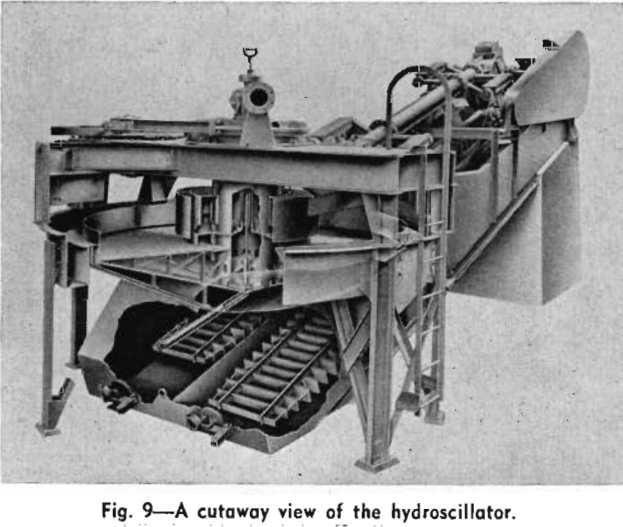

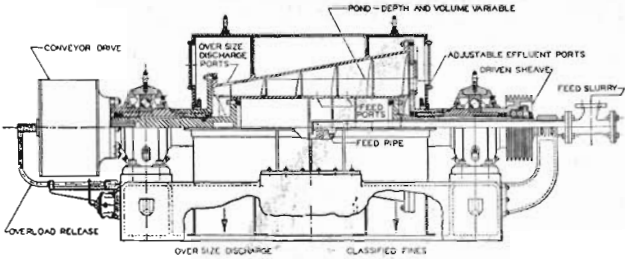

The hydroscillator is a rectangular tank set on a slope of 3 to 4 in. per ft. A bowl is superimposed on the lower end. The bowl bottom is an oscillating rubber-covered disk, perforated to allow hydraulic water introduced beneath the disk to set up a teeter bed and thus produce an oversize or rake product exceptionally free of slimes, and material minus the mesh of separation.

Centrifugal classifiers of this type are available in cone diameters from 18 to 54 in.

In the sand washer a set of buckets is attached to a circular frame rotated slowly on an inclined deck, which forms the bottom of a circular tank. The top of the tank side extending up from the heel becomes the overflow weir. Feed under pressure is introduced toward the center of the inclined bottom. Sand washers are available in 7, 9, and 12-ft diam.

Particles coarser than 20 mesh can be made to report in the overflow from unit-type classifiers when the ground ore or material contains a high percentage of true slimes. Such materials are cement rock and ores containing talc and clay. But these coarse particles, sometimes as large as ¼ in., are more in the nature of tramp oversize carried in suspension in a high-density classifier pool. The basic mesh of separation is more nearly at 20 mesh.

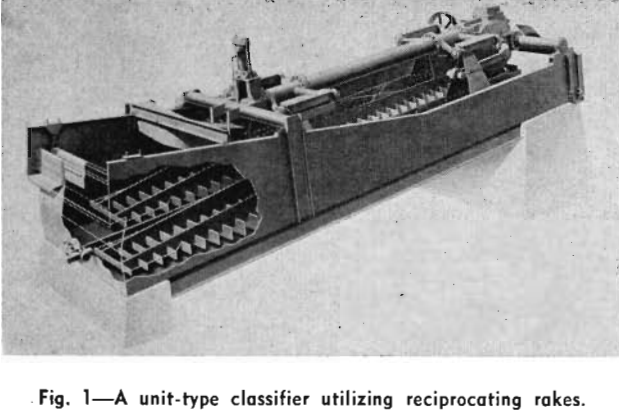

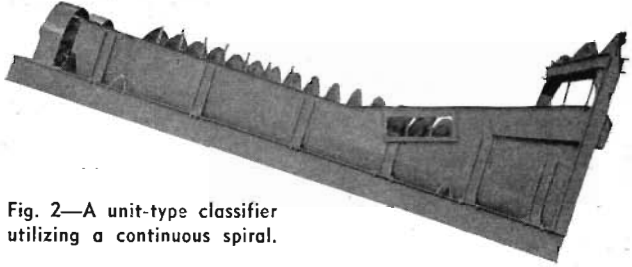

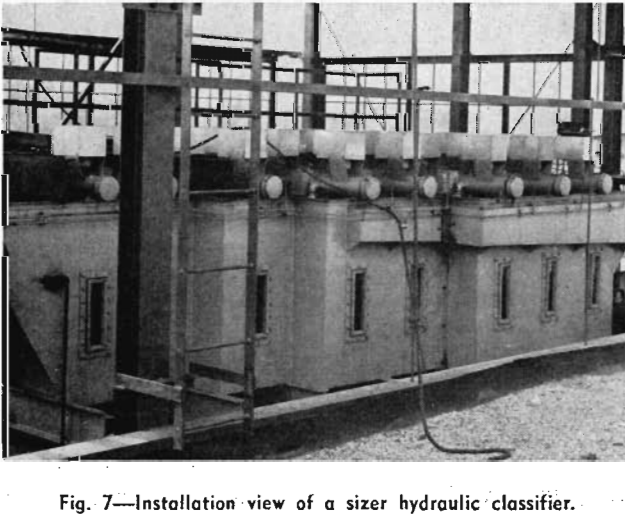

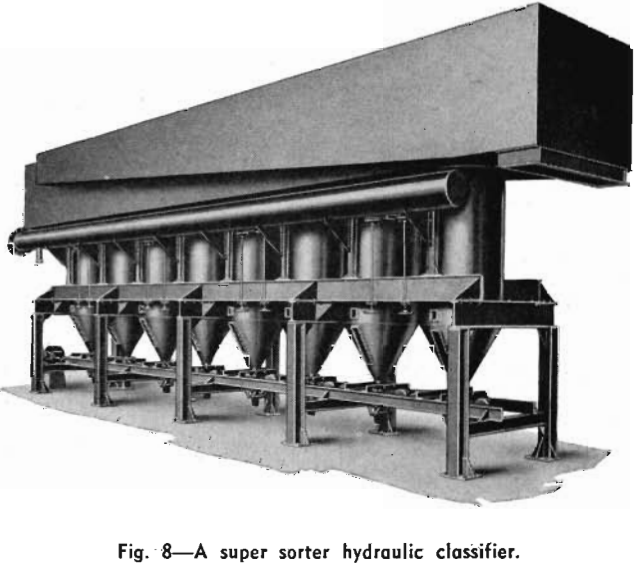

Unit-Type Classifiers

Limitations: Unit-type classifiers are commonly employed for two-product separations, overflow and rake product, with overflow solids ranging between 20 and 100 mesh. Maximum size of feed particle is normally 1 in., occasionally 1½ to 2 in. When specific gravity of the feed solids is 4.0 to 5.0, overflow should be limited to a top size of 28 to 35 mesh.

Control of water into these classifiers is very important, as separation at whatever mesh, 35, 48, 65, or 100, is made largely by the buoyancy or viscosity of the mixture of water and solids in the pool. Agitation of the sand-raking mechanism also affects mesh of separation. Excess water, contrary to the opinion of the uninitiated, ruins the separation by allowing too many particles of the desired size to drop down into the rakes or screws. Too little water, conversely, allows oversize particles to remain in suspension and contaminate the overflow.

Unit-type classifiers are also employed for final scrubbing, washing, and dewatering of granular products such as phosphate rock, ground silica, concrete sand, fine coal, limestone, precipitated alumina, and mineral concentrates from flotation and gravity concentration milling. Occasionally these classifiers size, wash, and dewater granular organic-chemical products in plastics and related fields.

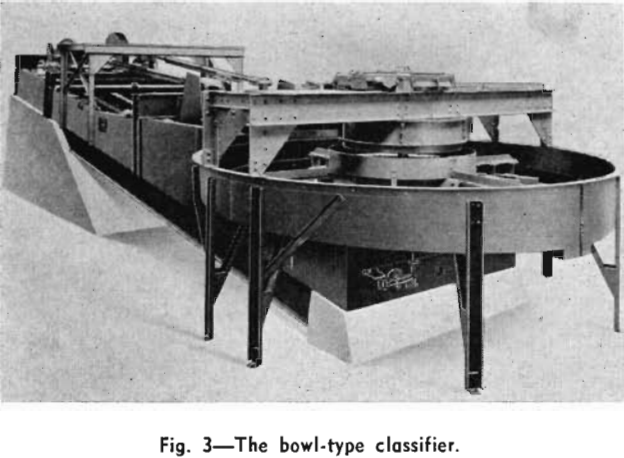

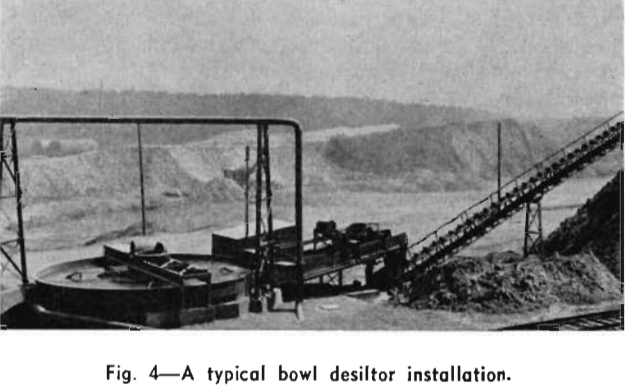

The Bowl Classifier

Limitations: The bowl classifier has been designed and developed for separations finer than are generally attempted in the straight or unit-type classifiers. For the more usual 2.65 to 3.0 sp gr materials, a two-product separation at 65 mesh is the generally accepted top limit. Separations within the range of 100, 150, 200, and 325 mesh are, however, more common. The raking mechanisms of this unit can handle a feed containing particles as large as ½ to ¾ in. For materials of 3.5 to 5.0 sp gr, the top limit for a two-product separation with the bowl classifier is about 100 mesh, and because of the heavier gravity, fineness of separation can be extended below 325 mesh (43 microns) or down to about 20 microns (750 mesh).

The Multi-Deck Washing Classifier

In some processing operations it becomes desirable to wash a contaminating chemical solution from the rake product of a bowl or a unit-type classifier. In most instances more than one washing stage is required, and one, two, or three additional raking sections are added in cascading fashion to make a unit-type or a bowl classifier with multidecks for the counter-current washing of the sand product. Fresh water is added on the final deck and progresses downward counter-currently to movement of the solids. The wash water flows from one raking section to the next lower section by means of interconnecting launders.

The Hydroseparator

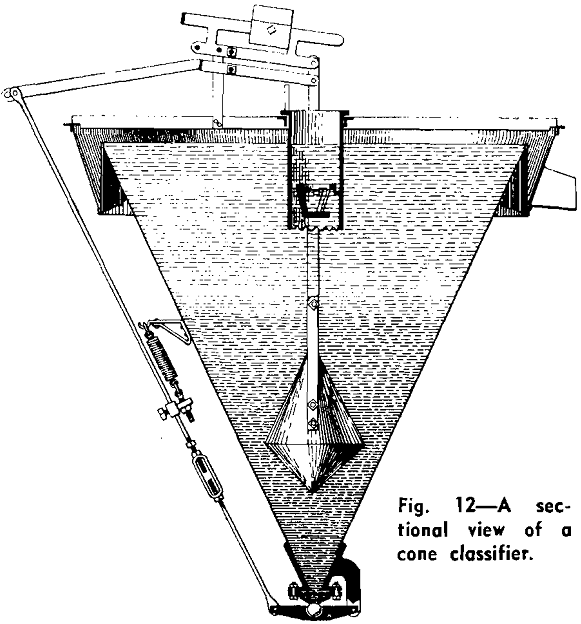

Limitations: In the hydroseparator a widening in the line of flow allows the coarser particles to settle out from the suspension. Only the cone classifier is simpler in construction. The hydroseparator is frequently misused because its limitations are not fully recognized.

Classification efficiency of the hydroseparator is appreciably lower than that of the unit-type and bowl classifiers. It depends entirely on gravity settling for the separation, and the overflow can be set to contain around 1 pct or less of particles plus the mesh of separation. This is done at the expense of allowing a relatively high separation of particles minus the mesh of separation to settle into the underflow, resulting in low classification efficiency. The underflow will always contain about 40 to 60 pct of the material minus the mesh of separation, the higher percentage being approached when coarse separations in the 35 to 65 mesh range are adopted.

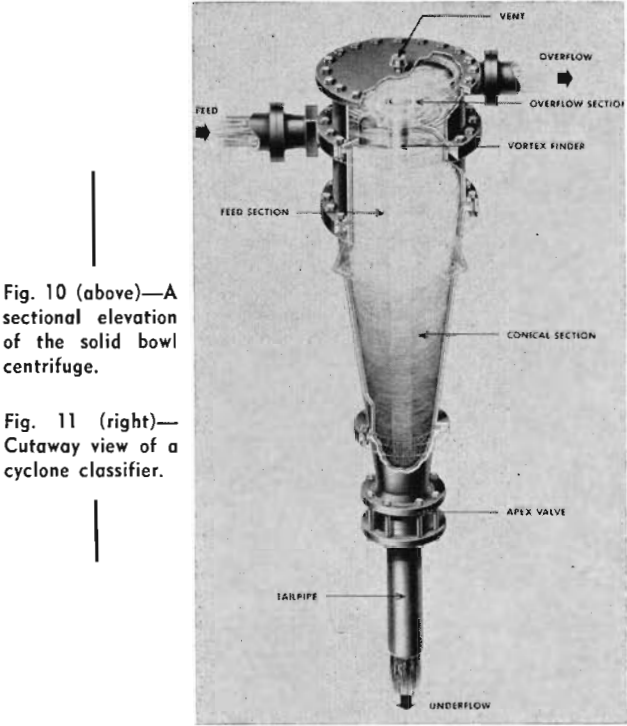

Centrifugal Classifiers

Limitations: 1—The solid bowl centrifuge. This unit can develop centrifugal forces up to 1000 times gravity, and with such characteristics it is the only commercial unit that will accomplish reasonably efficient separations down in the low micron range. Ordinarily the solid bowl centrifuge is limited to relatively fine separations from about 100 mesh to as low as 5 microns.

2—The stationary cone or cyclone classifier. In this type of classifier the centrifugal force is set up by injection of the feed tangentially under pressure. Pressure is generally maintained at 15 to 20 psi but is raised up to as much as 80 to 100 psi when extremely fine separations are necessary.

The cyclone, having a steep-angle cone section of 20°, is in its present design usually limited to separations between 147 microns (100 mesh) on the coarse side and 10 to 20 microns on the fine side. It is limited in that abrasive action of any appreciable amount of coarse particles in the feed causes excessive wear when high pressures are used.