Over the past quarter of a century, the success of the hydrocyclone as a classifier in closed circuit grinding installations has permitted the introduction of the cyclone into virtually all fields of wet industrial processing. Research and experience gained in these applications have established the optimum cyclone sizes and designs necessary to provide the required performance. Although cyclones are used in widely diverse liquid-solid applications, their use for ultrafine separation clearly demonstrates the importance of a familiarity with previous case studies.

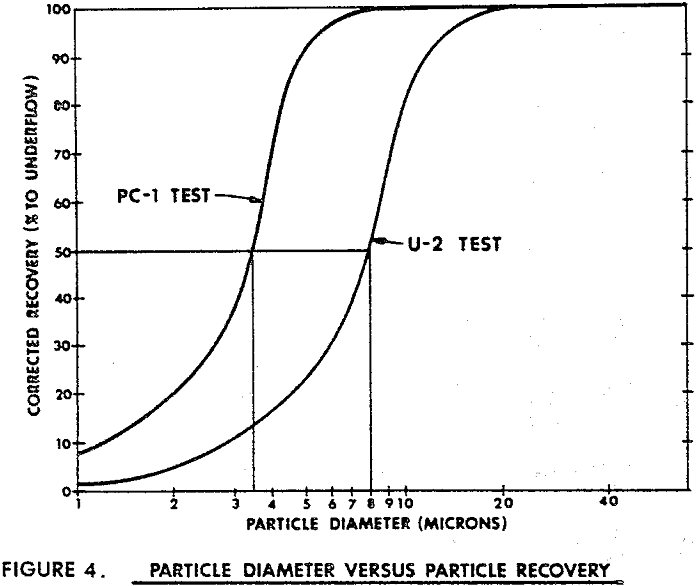

The variables that affect cyclone performance are especially important when making separations on the order of 10 microns. As with larger cyclones, the characteristics of the incoming feed are important to consider, since all cyclones are feed sensitive. In addition, the configuration of the typical large diameter cyclone must be specifically adapted to allow small diameter cyclones to make fine separations.

The most important construction variable is cyclone diameter. The driving force behind a cyclone separation is the accelerated gravitational forces which are inversely proportional to the radius of the cyclone cylinder. A small diameter cyclone is used to make ultrafine separations to utilize these high G values.

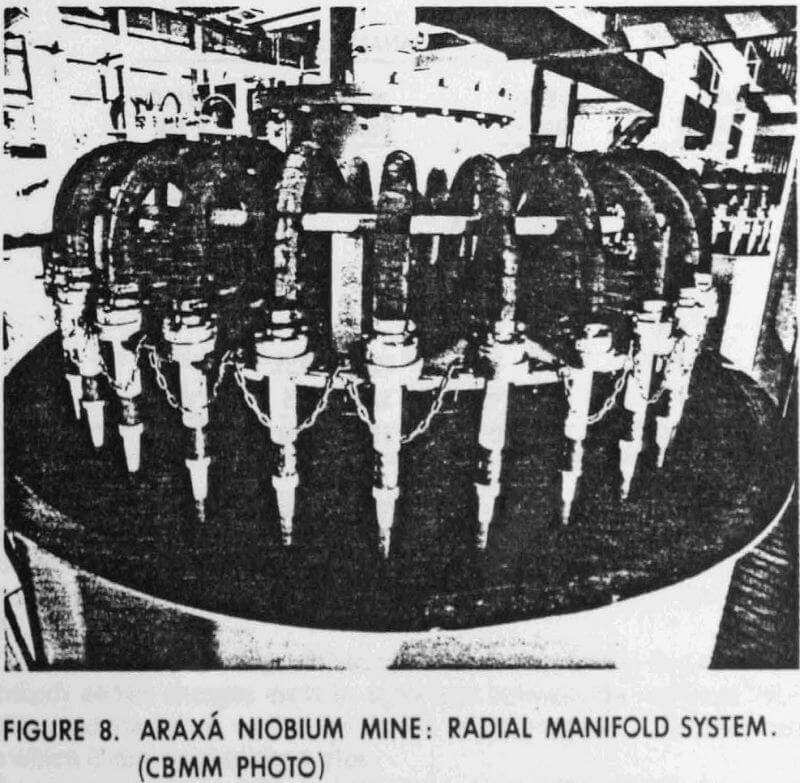

Small diameter cyclones are usually built with a long cylinder section, with a conical section of narrow included angle. The internal surfaces must be smooth and concentric around the cyclone axis. Wear resistant ceramics or molded plastics and elastomers are frequently used to give a continuous surface, free of any irregularities.

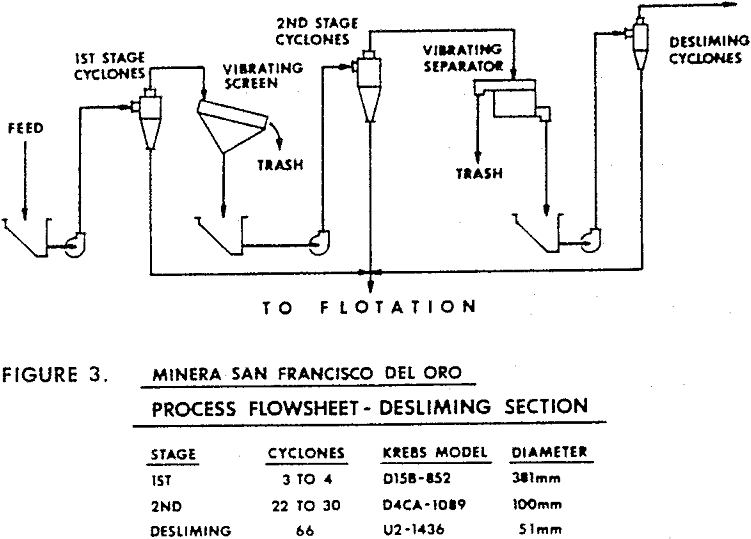

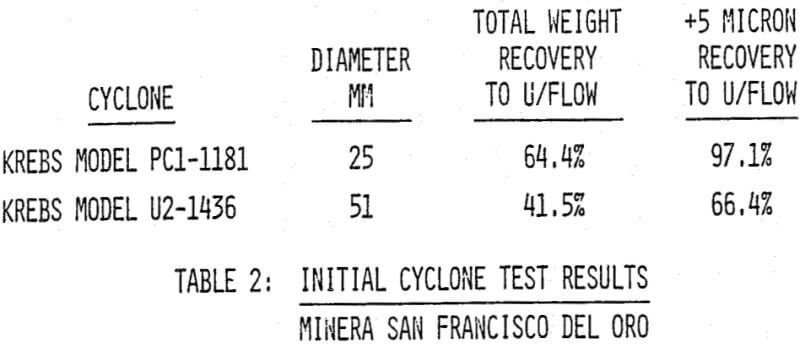

Minera San Francisco del Pro Concentrator, Mexico: the original process was designed to recover fluorite fines from a feed stock consisting of tails from an old zinc ore beneficiation plant. This process consisted of an attrition mill to break up the fine but solidified tailings followed by one stage of three to four operating 381 mm diameter Model D15B-852 Krebs Desliming Cyclones. The overflow from this cir-able to eliminate the plugging problems by installing non-blinding vibrating screens to have removed the fibrous contaminants.

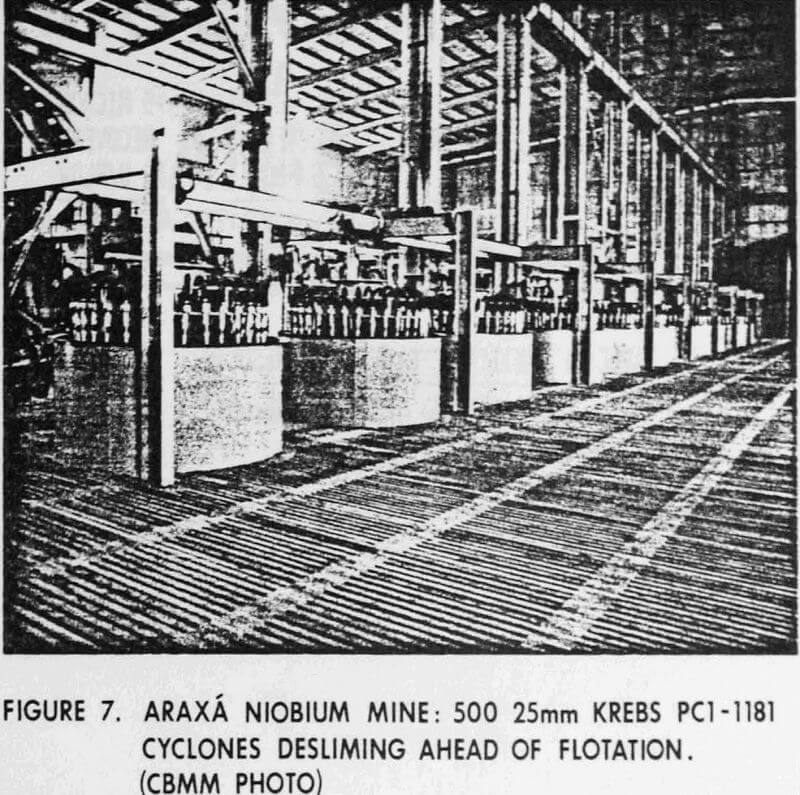

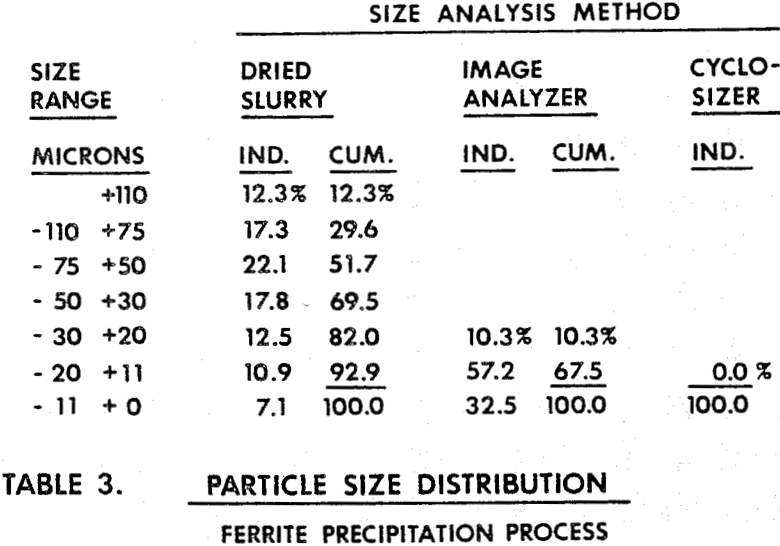

Araxa Niobium Mine, Brazil: A unique case study involving a rare but important element is the Araxa Niobium Mine in Brazil. Niobium, also known as Columbium, is used primarily as a ferro alloy adding significant strength to mild steel. The niobium deposit is found in a pyrochlore-rich lateritic ore, which is exceptionally high in -5 micron slimes. Since the niobium ore values are concentrated by slimes sensitive flotation, an effective ultrafine separation using cyclones is required.

Recovering Filter Aid Particles from Filter Cake: An effective method to recover a high percentage of filter aid particles with a high product quality is a process using cyclones. The particles can be reused, provided an effective 5-10 micron separation is made.