Aqueous pressure oxidation at low temperature, although desirable from a process engineering and operations point of view, presents unique problems when temperatures approach 160°C (320°F). In developing the pressure oxidation process for the Lone Tree Mine, elemental sulfur formation and agglomeration with pyrite proved to be a problem.

The Lone Tree Mine currently operates a 1.36 million mt/yr (1.5 million st/yr) heap leach operation on an oxide gold ore grading 3.1 g/mt (0.09 oz/st) of gold. The project’s annual production from the heap leach operation is estimated at 120,000 ounces. The oxide ore is considered free milling with heap leach gold recoveries in the 80 to 90% range.

Initially, Lone Tree began testing several potentially low cost sulfide processing methods with minimal success. The predominant low cost process alternatives tested were:

- Fine grinding

- Pre-aeration with air and oxygen

- Hot lime and caustic pre-treatment

- Ferric sulfate pre-treatment

- Chlorination and flash chlorination

- Flotation

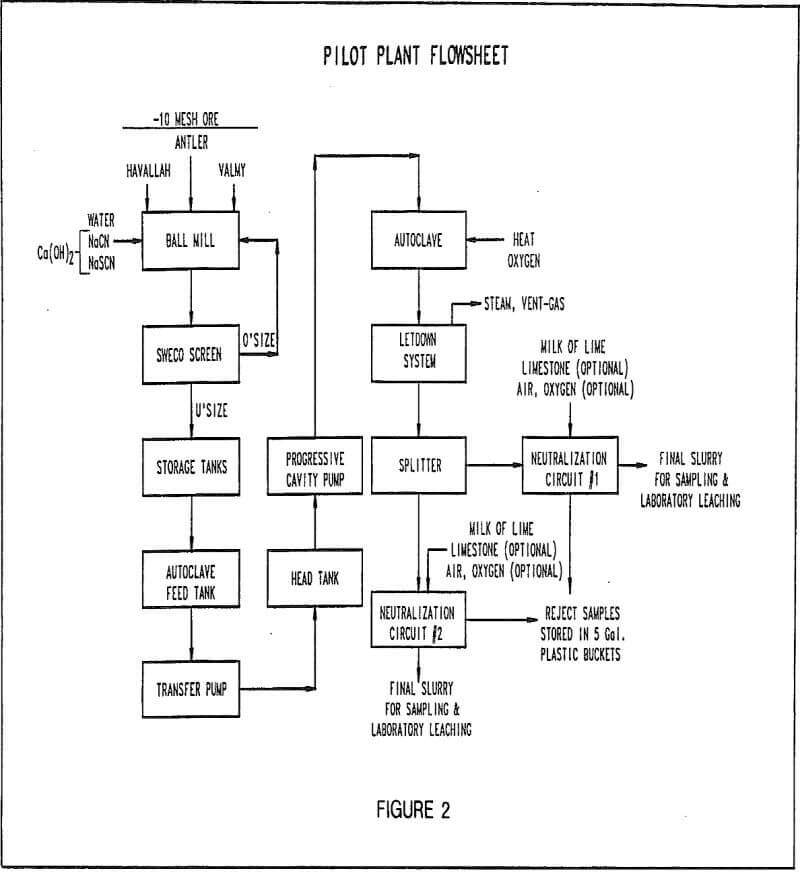

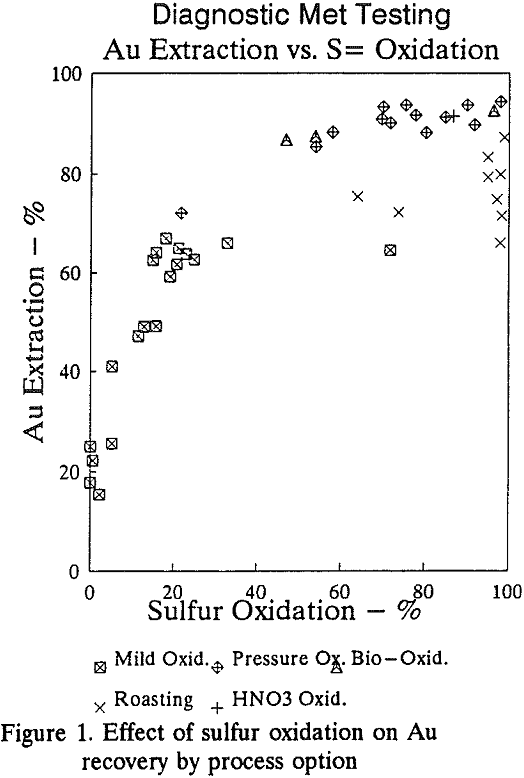

After evaluating the initial test results, Lone Tree began more detailed process development on pressure oxidation, nitric acid oxidation, bio-oxidation and roasting. Work was directed at proving the advantage of partial sulfur oxidation for the three aqueous process options and on trying to improve gold recovery by roasting.

The Process Ranking Study took four months to complete and was carried out in five phases:

Phase 1: Detailed review of all available mineralogical, metallurgical and technical data.

Phase 2: Development of flowsheets and GA’s for each process.

Phase 3: Detailed engineering adequate for +/-20% cost estimate.

Phase 4: Capital and operating cost estimates.

Phase 5: Financial and process risk analysis.

The economics of the process alternatives were evaluated with a simplified discounted cash flow model. At a gold price of $400/oz, the net present values (NPV) at 15% discount rate and the discounted cash flow rates of return (DCFROR) for the process alternatives were calculated.

Four inch core drilling was conducted by the Lone Tree geological staff to obtain a large enough quantity of representative material from the predominant sulfide ore types.

Testing proceeded using the above design conditions, until a problem developed involving the formation of excessive amounts of elemental sulfur in the autoclave. The elemental sulfur agglomerated with sulfides to make “prills”.

Once the prills were discovered, pilot plant testing was suspended in order to evaluate the problem and formulate a solution.

Gold recovery improved to levels obtained from batch laboratory testing, although at the higher operating temperature and pressure.

Study of the individual autoclave runs support this conclusion, but show that the sulfide oxidation end point for different ore varies widely. The relative percent of fine grained sulfides (containing most of the gold) accounts for the majority of easily oxidizable sulfur. Some Lone Tree ores achieve low sulfur oxidation, as low as 40-50%, while others achieve as high as 80-90% at the same operating temperature.