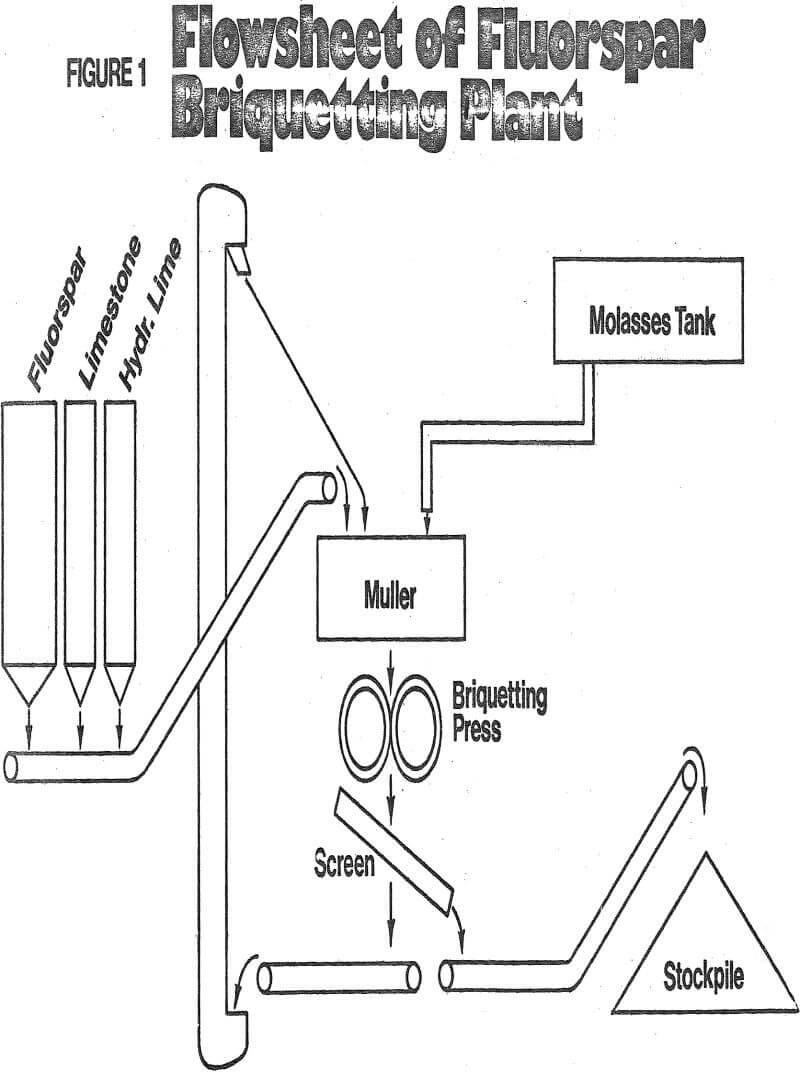

The Oglebay Norton Company has traditionally been a supplier of metallurgical grade fluorspar gravel to the American steel industry and, in the early sixties, fluorspar pellets were entered into the market. The gravel has been imported from Mexico, the pellets were produced by the Minerva Company in southern Illinois.

Use of waterglass or tall oil requires a double drying operation; heat treatment of the briquets is particularly critical as a certain, uniform, minimum temperature of the product must be attained in order to render the binder insoluble in water. Sugar and hydrated lime, on the other hand, form a water insoluble solid bond almost instantaneously and without extraneous heat.

The sugar-lime bonded briquets have proven to be resistant to any wetting, soaking, freezing, and thawing that might occur before their use in the customers furnaces. Because of rumors to the contrary, we had an independent laboratory conduct a special study in the course of which the briquets were subjected to five cycles of soaking, freezing, and thawing. After thawing, but before drying, the pillow shaped briquets were subjected to a beam test which showed that considerable force had to be exerted before the briquets broke in two.