Hydrostatic Bearing Type Center Mechanism

Development of the Hydrostatic Bearing Mechanism evolved from the caisson thickener design. Conventional thickener mechanisms are driven by gearing which rides on ball or roller

Development of the Hydrostatic Bearing Mechanism evolved from the caisson thickener design. Conventional thickener mechanisms are driven by gearing which rides on ball or roller

Figure 125, A and B shows typical arrangements using floating gold washing and gold-saving plants (“boats”). Figure 125, C, is a plan of an operation

Hydraulicking: In hydraulic mining a stream of water under high head is employed to break down the bank and excavate the gravel and to sweep it

Table of ContentsSmall-Scale Dewatering ExperimentsLarge-Scale Clay Dewatering Experiments Phosphatic clay waste is one of the principal waste products resulting from the mining and benefication of Florida phosphate

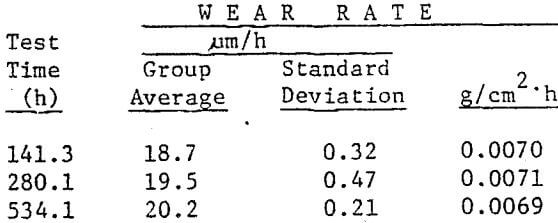

Table of ContentsResultsMarked Ball TestingMarked Ball Wear TestsSurface Morphology of Grinding BallsElectrochemical MeasurementsMarked Ball Wear TestsLaboratory Batch Flotation TestsPercent Martensite Hardness Marked Ball Wear TestsScanning

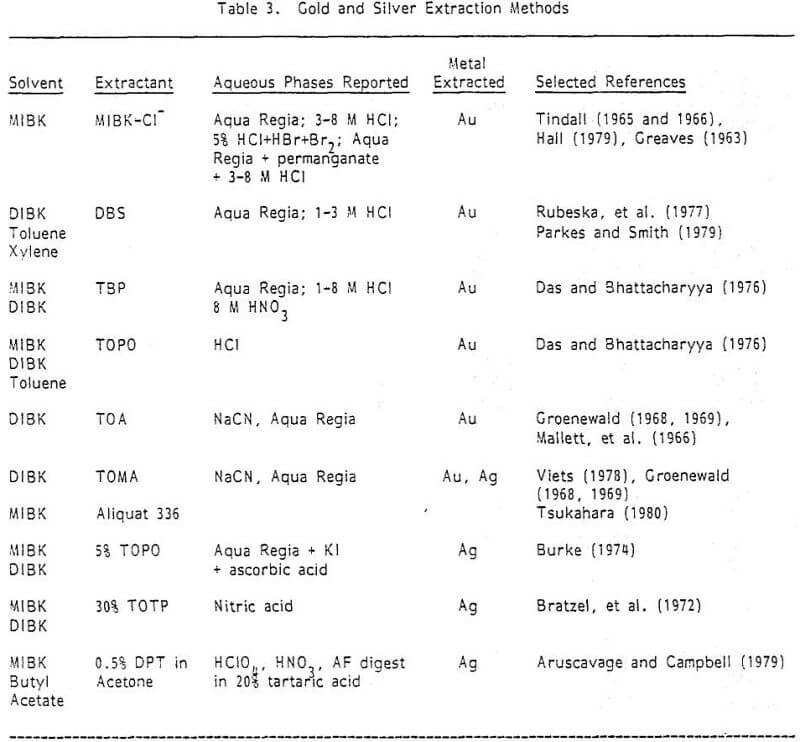

Table of ContentsInterferencesDetermination of Gold and Silver from a Single Sample Preparation Flameless AAS provides a means to increase flame AAS sensitivity, by up to

Gold values in the surveyed sulfide-poor rock units proved to be generally even lower than those in sulfidic sandstone. As a further check on this

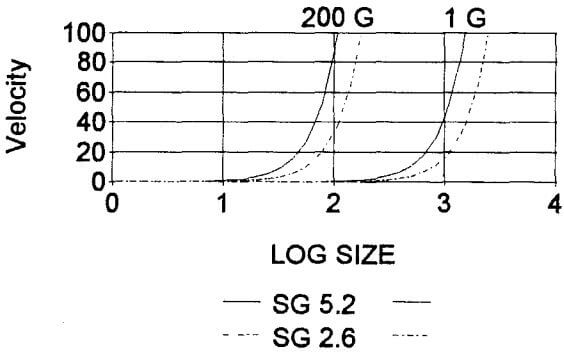

Table of ContentsCapacityEfficiencyPulp AccelerationParticle Shape vs enhanced GravityBackground theoryModel B Enhanced Gravity Separator Enhanced gravity separation devices (centrifuges) have been patented for over a century

A number of compressive tests were conducted on iron ore pellets obtained from the Samarco pelletizing plant located at Ponta Ubu, Brazil. These pellets are

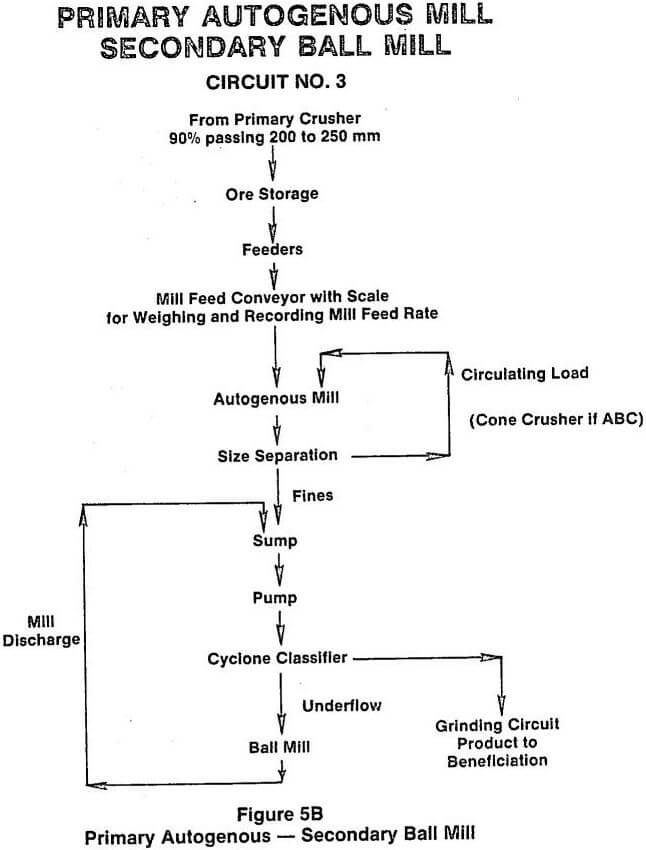

Ff the drill cores indicate that the ore could contain sufficient lumps in the sizes needed for ore media in autogenous and semi-autogenous grinding, then