Metallurgy Problems

Table of ContentsParting LimitsAging While reflecting on the subject of my present paper, I soon realized that it would be very difficult to say something

Table of ContentsParting LimitsAging While reflecting on the subject of my present paper, I soon realized that it would be very difficult to say something

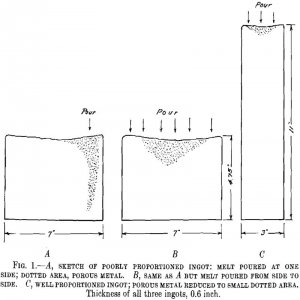

Table of ContentsMetals used in AlloyingGas and Electric MeltingDefects in IngotsSurface DefectsIngot ProportionsPorous IngotsDeoxidizersUse of Deoxidizers in Sterling SilverUse of Phosphorus in Gold AlloysCalcium Boride

Table of ContentsConventional “Hungarian” Riffle DesignsHydraulic RifflesMacon Self-Cleaning Filter For Hydraulic Riffle Operation In-depth research on gold recovery in the Yukon conducted in 1990 by

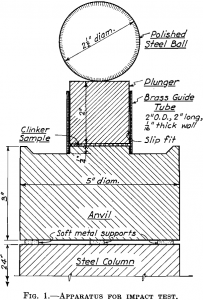

Table of ContentsImpact Grindability TestGrindability Test in Analysis of Mill PerformanceGeneral Discussion Grinding costs are an important item in cement manufacture, and the cost of

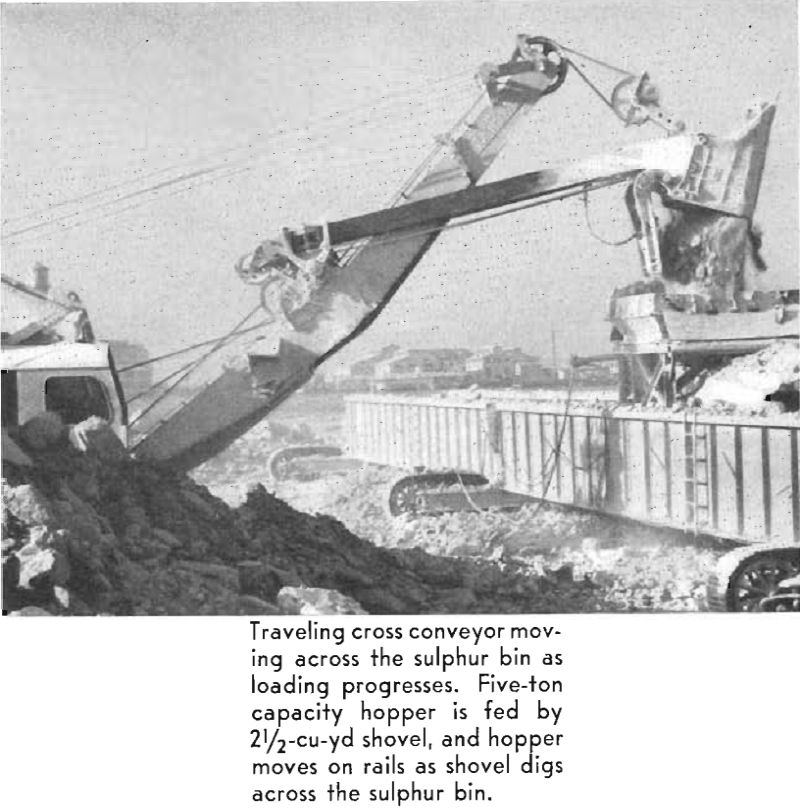

The Freeport Sulphur Co. built a portable screw crusher in 1944 that solved a problem that none of the crusher manufacturing companies contacted were able

Table of ContentsSafetyBill of Materials ShippedUnpackingTable Installation & AssemblyGeneralAlignmentLaundersFeed Box / Wash water BarPre-Start up ChecksHolman 2000 OperationFeedStrokeDeck TiltWash WaterProduct off TakeGeneral Preventative MaintenanceHolman Head

Here is my list of the Top 15 largest and biggest mines in the world: They are economically big and physically large, taking a

Table of ContentsA JAW CRUSHER DESIGNED FOR OPERATORSJaw Crusher ToggleTOGGLE REPLACEMENT COSTAutomatic LubricationCapacitySizes and Dimensions Jaw crushers include Superior, Type “B” Blake, Fine-Reduction, and Dodge — sizes,

As it is malleable, no crusher can crush gold but, all rock crushers can crush rock with gold minerals in it. Small gold prospectors are

Table of ContentsDiscussionWritten Discussion The speed of drilling rock has become an important factor in mining operations, while the placement of holes, kind, and quantity

Images for illustration purposes only. No rights can be delivered from the illustrations.

911METALLURGY CORP. can not be responsible for errors in typography or photography.

Copyright 2012-2024 911Metallurgist | All Rights Reserved